$5,600.00 – $6,400.00

Using a well-known brand laser generator (Raycus, JPT, Max, IPG), the pulse width and frequency are independently adjustable and can maintain a stable peak power output, suitable for a wider range of cleaning scenarios. The high photoelectric conversion rate ensures the laser power and makes the cleaning effect better. Acctek Laser can design different configurations to meet customer needs.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the clean itself. It can also increase welding output by reducing the downtime of fiber laser cleaning machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser cleaning machine.

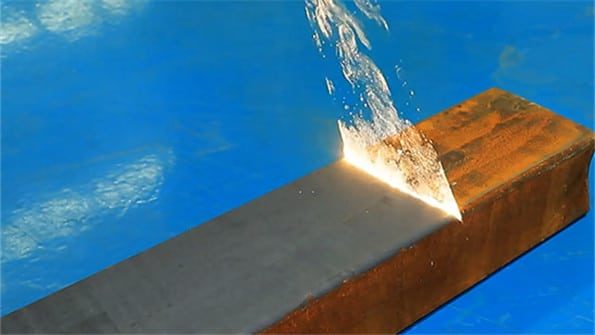

The laser cleaning head is ergonomically designed, small in size, comfortable to hold, and easy to control and operate. The hand-held cleaning head is easy to hold can be used for a long time, and can be operated at any angle, making cleaning more convenient and flexible.

Acctek Laser provides high-performance, intuitive, and easy-to-use operating systems. You can quickly set cleaning power, width, and other parameters through the screen, and provide a better cleaning effect. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

| Model | AKQ-1000 | AKQ-1500 | AKQ-2000 | AKQ-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | |||

| Pulse Formation | Q-Switched (Quality Factor) | |||

| Laser Generator | Raycus, Max, BWT | |||

| Output Range (If Adjustable) | 0-100% | |||

| Cleaning Efficiency | 12㎡/h | |||

| Scanning Width | 10-80mm | |||

| Cleaning Width | 80-450mm | |||

| Fiber Length | 10-15m | |||

| Expected Focal Distance | 160mm | |||

| Cooling Type | Water Cooling | |||

| Comparison | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Cleaning |

|---|---|---|---|---|

| Washing Method | Non-Contact Cleaning | Contact Cleaning | Abrasive Contact Cleaning | Non-Contact Cleaning |

| Harm To Base Material | None | Yes | Yes | None |

| Washing Efficiency | High | Low | Low | Mid |

| Consumable | Power | Chemical Detergent | Abrasive Paper, Grinder, Abrasive Stone | Dry Ice |

| Washing Result | Very Good, Very Clear | Medium, Uneven | Medium, Uneven | Good, Uneven |

| Precision Washing | Accuracy Controllable, High Precision | Uncontrollable, Low-Precision | Uncontrollable, Medium-Precision | -Uncontrollable, Poor Precision |

| Safety/Environment | No Pollution | Chemical Pollution | Dust Pollution | No Pollution |

| Operation | Easy to operate, portable, or automation optional | Complicated processes, higher technical requirements of the operator, and Pollution prevention measures are required | With more time & manpower, pollution prevention measures are required | Easy to operate, portable, or automatic |

| Investment | High investment in machines, but no consumable, low maintenance cost | Low investment in machines, but expensive consumables | Medium investment in the machine, high manpower cost | Medium investment in the machine, high consumable cost |

The price of a 3000w laser cleaning machine can vary based on several factors, including brand, specifications, features, and additional options or accessories. Prices may also be affected by suppliers, location, and market conditions and change over time. Typically, a 3000w laser cleaning machine costs between $5,700 and $6,500. Please note, however, that these are approximate prices and actual prices may vary significantly.

Factors that affect the price of a laser cleaning machine include laser generator type, build quality, automation features, control systems, scanning systems, safety features, warranty, and aftermarket support. Additionally, any optional accessories or customizations you require may also add to the overall cost. For the most accurate pricing information, I recommend contacting multiple suppliers, comparing their offerings, and discussing your specific requirements to obtain a tailored quote.

AccTek Laser is a professional laser cleaning machine manufacturer, if you want to get accurate price information for a 3000w laser cleaning machine, you can contact us. We can also provide you with details on pricing and any additional costs associated with the machine, such as shipping, installation, or training. Additionally, our engineers will provide you with information on pricing and options, and recommend the best laser cleaning machine for your application and budget.

The 3000w laser cleaning machine can effectively clean various surfaces. The versatility of laser cleaning technology allows it to be used on a variety of materials, including:

These are just a few examples of surfaces that a 3000w laser cleaning machine can effectively clean. It is important to note that the effectiveness of laser cleaning on a particular surface depends on factors such as the optical properties of the material, surface texture, and the type of contamination being removed. Before using a 3000w laser cleaning machine on any surface, it is recommended to test or consult an expert to ensure compatibility and determine the proper laser settings for a particular cleaning application.

The 3000w laser cleaning machine has several limitations when it comes to cleaning materials and surfaces:

Thermal Damage: Some materials are sensitive to heat, and the high energy of the 3000w laser can cause thermal damage, warping, or structural changes to these materials.

In summary, the 3000w laser cleaning machine performs well in certain applications, but its limitations make it necessary to consider the specific cleaning needs and conditions when choosing a cleaning method.

Yes, like any piece of sophisticated industrial equipment, a 3000w laser cleaning machine requires regular maintenance and care to ensure its optimum performance and longevity. While specific maintenance requirements may vary by make and model, here are some general maintenance aspects to consider:

It is recommended to refer to the manufacturer’s documentation, owner’s manual, and maintenance guide specific to the 3000w laser cleaning machine you are using. They will provide detailed instructions on maintenance procedures, recommended service intervals, and any specific considerations for your particular model. Regular maintenance and upkeep will not only help ensure optimal machine performance but also contribute to the longevity and reliability of your laser cleaning system.

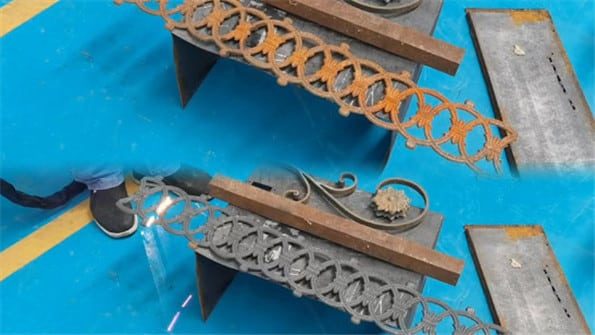

The 3000w laser cleaning machine can effectively clean various materials and surfaces in various industrial applications. Some common applications where it can be used effectively include:

These are just a few examples of the many applications where a 3000w laser cleaning machine can be used effectively. The versatility and precision of laser cleaners make them suitable for demanding cleaning tasks that require efficient and precise removal of different surface contaminants.

Yes, 3000w laser cleaning machines usually allow adjustment of power output or intensity. Laser cleaning machines are designed with control systems that enable operators to adjust various parameters, including power output, pulse duration, and laser beam characteristics, to optimize the cleaning process for different materials and surface conditions.

These adjustable parameters give operators the flexibility to optimize the power output or intensity of the laser cleaning process for specific materials, contaminants, and cleaning requirements. It allows them to adjust cleaning parameters to achieve the desired results while minimizing the risk of damage to the surface being cleaned. It is important to note that specific controls and adjustment capabilities may vary by the make and model of the laser cleaning machine. It is recommended to refer to the owner’s manual of the machine or consult the manufacturer for details on adjusting the power output or intensity.

The 3000w laser cleaning machine will produce a lot of noise during operation. Noise levels may vary depending on factors such as the design of the machine, the cooling system employed, and the specific cleaning process being performed. Laser cleaners usually incorporate cooling systems, such as fans or water cooling, to dissipate the heat generated by the laser source. These cooling systems affect the overall noise level of the machine. Additionally, the process of laser cleaning itself involves the interaction of the laser beam with the surface being cleaned, which creates additional noise.

To reduce noise, many laser cleaning machines are equipped with noise reduction measures. These measures can include thermally insulated enclosures, soundproofing materials, or the use of quiet cooling systems. These features are designed to minimize the noise produced by the machine and provide a more comfortable working environment.

It should be noted that the noise level of 3000w laser cleaning machines will still vary, and some machines may produce more noise than others. When considering installing a laser cleaning machine, it is advisable to consult the manufacturer or supplier for details regarding noise levels and any specific noise reduction measures implemented in their particular model. In some cases, additional noise reduction measures may be required, depending on the noise sensitivity of the environment or specific regulations. This may involve implementing further soundproofing measures, such as isolating machines in separate rooms or using additional noise-dampening materials.

The 3000w laser cleaning machine is a powerful tool that requires several safety measures to ensure the safety of the user. These measures are implemented to minimize the risk of accidents, injuries, and exposure to harmful laser radiation. Here are some common safety features and measures found in laser cleaning machines:

It should be noted that the specific safety measures of different laser cleaning machine models and manufacturers may be different. Users should carefully read the user manual and safety guide provided by the manufacturer for the specific 3000w laser cleaning machine they are using to ensure that the recommended safety procedures are properly understood and followed.

At AccTek Laser, we understand that different businesses have different needs, which is why we offer you a range of models to choose from. Whether you need a portable mini laser cleaning machine or a high-speed industrial laser cleaning machine, we have the right machine for you. Invest in our fiber laser cleaning machines and take your cleaning capabilities to the next level.

With years of experience in laser cleaning technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser cleaning machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser cleaning machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser cleaning machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cleans every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser cleaning machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for 3000W Laser Cleaning Machine

Ming –

Impressive precision and reliability. Streamlines cleaning processes and improves workflow. Highly recommended for industrial use.

Eva –

Reliable performance, minimal maintenance. Boosts efficiency and extends equipment lifespan. A must-have for industrial cleaning.

Noah –

Versatile cleaning machine for various surfaces. Enhances safety and efficiency in operations. Delivers consistent performance and exceeds expectations.

Koki –

Exceptional cleaning power saves time and effort. Essential for maintaining cleanliness and productivity in the workplace.