$6,500.00 – $9,200.00

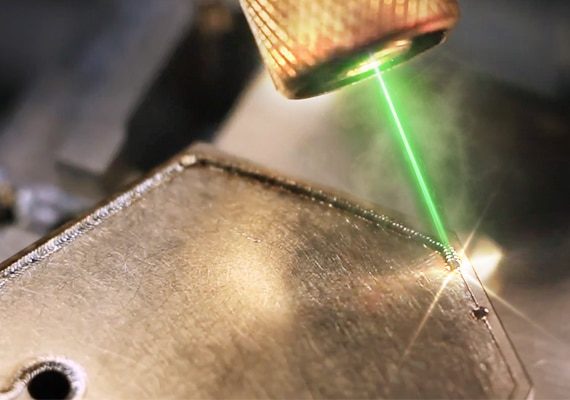

Using well-known brand laser generators (Raycus, JPT, Reci, Max, IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better. AccTek can design different configurations to meet customer needs.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

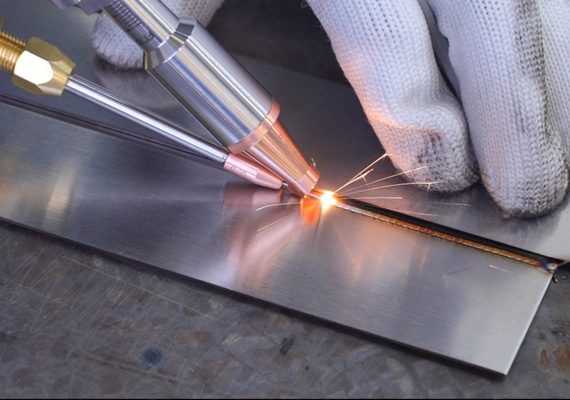

The laser welding gun is ergonomically designed, light in shape, comfortable to hold, and easy to control and operate. The hand-held welding gun is easy to hold and can be operated at any angle, making welding more convenient and flexible.

AccTek provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | |||

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1080nm | |||

| Way of Working | Continuous/Modulation | |||

| Speed Range | 0-120mm/s | |||

| Repeat Precision | ±0.01mm | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Cooling Water | Industrial Thermostatic Water Tank | |||

| Material | Welding Form | Thickness (mm) | Laser Power (W) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q235B) | Butt Welding | 0.5 | 3000 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 3000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 3000 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 3000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 3000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 3000 | 110~120 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 3000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 3000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 3000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 3000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 3000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 3000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 3000 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 3000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 3000 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 3000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 3000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 3000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 3000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Copper | Butt Welding | 0.5 | 3000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 3000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 3000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

The initial cost of a 3000w laser welding machine can vary based on several factors, including make, model, features, and other options. Generally speaking, an industrial laser welding machine is a great investment due to its advanced technology and capabilities. 3000w handheld laser welding machines range in price from $8,500 to $25,000. Note that these figures are approximate only and may vary significantly based on the previously mentioned factors. For example, higher-end models with advanced features and automation may cost more.

Note that the initial cost is only one aspect of the overall investment in a laser welding machine. Other factors to consider include installation costs, training, maintenance, and any necessary accessories or consumables. Additionally, ongoing operating costs such as power consumption and scheduled maintenance should also be considered when assessing the total cost of ownership.

For accurate and up-to-date pricing, it is advised to contact a reputable laser welding machine manufacturer or supplier. AccTek Laser is a professional laser welding machine manufacturer. We can provide details on pricing and any additional costs associated with your machines, such as shipping, installation, or training. Our engineers will advise you on pricing and options and recommend the best laser welding machine for your application and budget. If you need it, please feel free to contact us.

Also, even if you now have an accurate price, we recommend that you contact us. You can decide which laser welding machine to buy by comparing the prices and services of different suppliers.

The ongoing cost of a 3000w laser welding machine can vary based on several factors, including the specific components of the machine, the frequency and intensity of use, and the type of material being welded. The following are some common consumables and parts that may require periodic replacement or maintenance:

Specific ongoing costs can vary widely depending on the make, model, and usage pattern of the machine. It is advisable to consult the manufacturer or supplier of your laser welding machine for accurate information on expected ongoing costs and a suggested maintenance schedule for the particular machine you are considering. They can give you details on the supplies and parts you will need and the associated costs.

The initial cost of a 3000w laser welding machine is affected by many factors. These factors may vary including manufacturer, model, and specific features or options included. Here are some key factors that can affect initial cost:

When evaluating the initial cost of a 3000w laser welding machine, be sure to consider your specific welding requirements, production needs, and budget. It is recommended to contact multiple vendors, compare quotes, and evaluate the features, quality, and support offered before making a purchasing decision. This will help ensure that you choose a laser welding machine that meets your specific requirements and provides the best value for your investment.

The 3000w laser welding machine can effectively weld a variety of metal materials. Here are some common metal materials that can be effectively welded with a 3000w laser welding machine:

The weldability of different metals will vary depending on their composition, thickness, and specific laser welding parameters. Before welding, it may be necessary to use appropriate shielding gases, filler materials, and surface preparation techniques to achieve a high-quality weld with minimal defects. Additionally, joint design, material thickness, and other factors can affect the welding process, and laser welding parameters may need to be adjusted.

If you have a specific metal material or application, it is advisable to consult the manufacturer or a welding specialist to ensure that the laser welding machine is suitable for your specific requirements. They can guide machine compatibility with metallic materials and offer advice on achieving the best welding results.

The maximum material thickness that a 3000w laser welding machine can effectively weld depends on a variety of factors, including the specific machine model, laser generator, beam quality, and the material being welded. While a 3000w laser welding machine can handle various thicknesses of material, it is important to consider the following:

Although the 3000w laser welding machine can handle materials of various thicknesses, its welding capacity is limited. For very thick materials, alternative welding methods such as hybrid welding (a combination of laser and other welding processes) or different welding techniques may be more suitable. To determine the maximum material thickness that a particular laser welding machine can handle, it is advisable to consult the manufacturer’s specifications or perform a test on a representative sample of the materials you intend to weld.

Operating a 3000w laser welding machine usually requires training and expertise to ensure the safe and effective use of the equipment. While specific requirements may vary based on local regulations and workplace policies, here are some general considerations for training and certification:

It is recommended that you consult local regulations, industry standards, and workplace policies to determine the specific training and certification requirements that apply to your region and industry. Additionally, the machine manufacturer or supplier can guide training resources or assist in arranging an appropriate training program for the operator. By ensuring operators are properly trained and certified, you can promote a safe working environment, reduce the risk of accidents, and optimize the performance of your laser welding machine.

Yes, 3000w laser welding machines usually have special power requirements due to their high power output and energy consumption. Here are some considerations regarding the power requirements of a laser welding machine:

It is recommended to consult the manufacturer’s specifications and guidelines for the specific power requirements of the 3000w laser welding machine you intend to use. Of course, the manufacturer or supplier can also provide you with details on voltage, current, phase configuration, and any other specific requirements for the proper operation of the machine. In addition, it is recommended to consult a qualified electrician or electrical engineer to ensure that your facility meets the necessary electrical requirements and can safely and efficiently meet the electrical needs of your machinery.

Laser welding machines are known for their high precision and speed, making them suitable for a range of applications. Compared with traditional welding methods, laser welding machines can provide higher welding speeds. The speed of laser welding depends on factors such as the material being welded, the design of the joint, and the capabilities of the particular machine. Laser welding can typically achieve welding speeds of several meters per minute, allowing rapid production in industrial environments.

The 3000w laser welding machines typically offer higher power output compared to lower-powered machines, increasing welding speed and productivity. The higher the power, the more energy the laser emitter can deliver to the workpiece, resulting in faster heating and welding. This is useful for welding thicker materials or achieving deeper penetration.

Productivity is affected by the speed of the welding process, the efficiency of the machine, and the overall workflow of the production environment. Laser welding machines can usually be integrated into automated production lines or robotic systems to achieve continuous and efficient operation. With proper setup and optimization, laser welding machines can increase productivity levels in the manufacturing process.

While laser welding offers advantages in terms of speed and productivity, it may not be the best choice for all applications. Factors such as material thickness, joint design, and accessibility can affect the welding process. Therefore, it is necessary to consider the specific requirements and consult an expert or manufacturer to determine the best welding solution for a particular application.

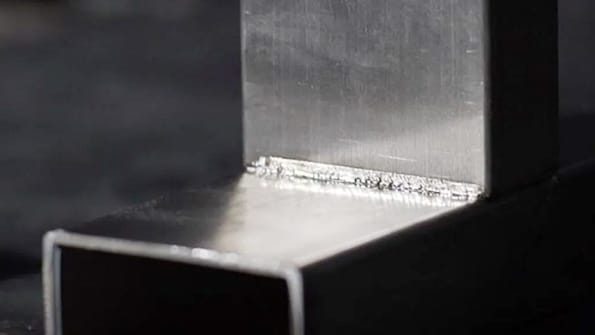

Simple preset selection ensures consistently high-quality laser welding results. The presets include wobble welding to accommodate wider seams and poorly assembled parts. Operators can instantly switch between different presets to easily handle multiple material thickness combinations.

The machine is ergonomic, compact, and proven to be the most comfortable and easy-to-use laser gun. The 2-step trigger and part contact sensor increase operator safety. It can quickly switch from standard laser welding to wire welding, making the operation simple and fast.

The clear logo on the rear of the machine makes connection easy and fast. Plug in the power cord and gas connections, attach the clips to the work surface, and you’re ready to start your welding operation. The ethernet computer connection provides access to advanced parameter settings for fine-tuning and saving welding process parameters.

Key switch control to protect the system from unauthorized welding operations. The emergency stop button can ensure that the machine can be shut down immediately when there is a problem. Safety interlocks verify the integrity of laser delivery to the welding gun.

4 reviews for 3000W Laser Welding Machine

Alice –

Impressed with its durability and performance. Makes welding tasks effortless. Highly recommended for manufacturing.

Sara –

Efficient and powerful. Simplifies complex welding jobs. Essential for our manufacturing process.

Anna –

Streamlines welding tasks. Boosts efficiency and accuracy. Great addition to our production line.

Leo –

Revolutionizes our welding process. Delivers consistent weld quality. A valuable asset for our workshop.