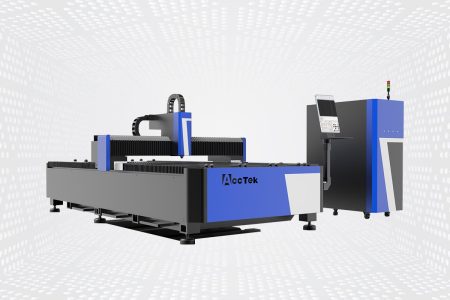

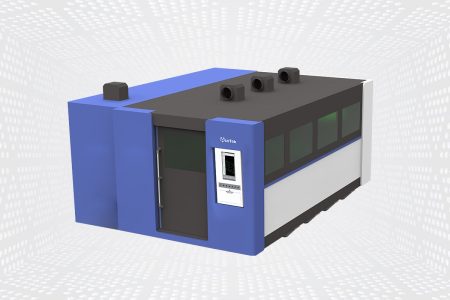

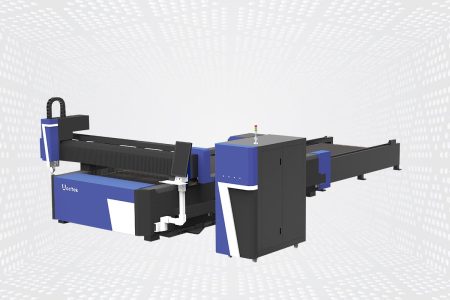

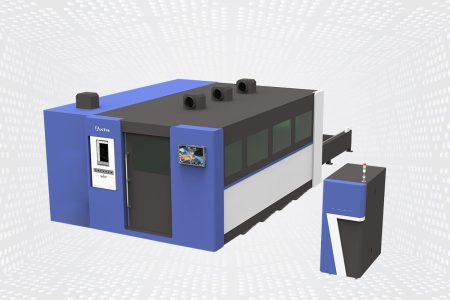

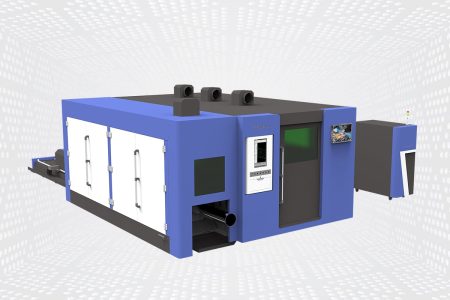

The environmental requirements of an 8000w laser cutting machine are crucial to ensure optimal performance, longevity, and safety. Proper environmental conditions help minimize machine downtime, maximize cutting quality, and ensure the machine operates efficiently. Here are the key environmental factors:

- Temperature and Humidity

- Operating Temperature: The machine should be kept in a room with a temperature range between 18℃ to 28℃ (64℉ to 82℉). Extreme temperatures can affect the performance of both the laser cutting system and its components, such as the laser source and electronics.

- Humidity: Ideal humidity levels should range from 40% to 70%. Too high or too low humidity can cause problems such as condensation on sensitive components or excessive dust buildup.

- Ventilation and Air Quality

- The machine requires proper ventilation to prevent overheating. It is essential to provide adequate airflow to the machine, especially around the laser generator, chiller, and electronics. Proper ventilation also helps dissipate heat generated by the cutting process.

- Clean Air Supply: The environment should be free of corrosive gases, dust, and other contaminants that could affect the cutting performance or damage internal components.

- Power Supply

- Stable Electrical Supply: The machine should be connected to a stable power source with the required voltage and current. Power fluctuations or interruptions can negatively affect the laser-cutting process.

- Dedicated Circuit: It’s advisable to use a dedicated electrical circuit for the machine to ensure consistent power delivery and to avoid overloading other systems in the facility.

- Space and Clearance

- The machine should be installed in a spacious, clean environment with adequate clearance around the system for maintenance, cooling, and air circulation. The workspace should allow easy access to all parts of the machine for operation and servicing.

- Flooring: The floor should be level and strong enough to support the weight of the machine. It should also be clean and free of any debris or materials that could cause operational issues.

- Safety and Noise Considerations

- Noise: The laser cutting machine generates significant noise, especially during operation. It is essential to install the machine in a location where noise levels can be managed, possibly using noise-reducing materials or enclosures.

- Safety Protocols: The machine should be placed in an area that complies with safety standards for laser equipment. Proper laser shielding and safety protocols should be in place to protect operators from potential laser exposure.

- Cooling System

- Adequate Cooling: The cooling system (typically involving a chiller or water-cooled unit) requires a constant and controlled coolant temperature. It should be installed in an area where the coolant flow can be maintained effectively, and any potential leaks can be addressed.

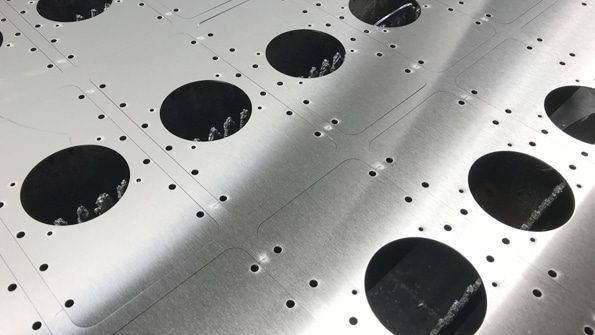

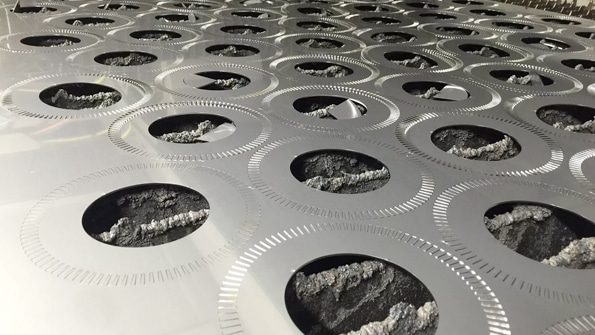

- Dust and Fume Extraction

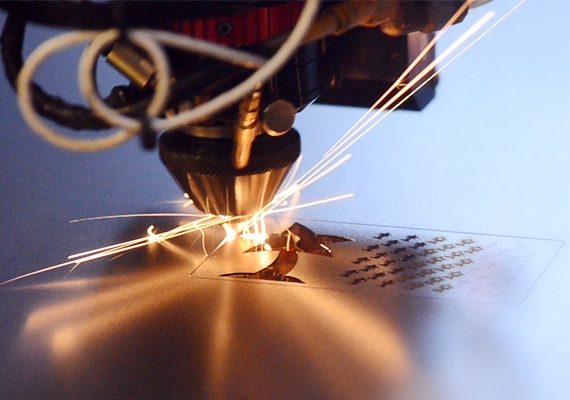

- Since laser cutting involves high-heat processes, the operation generates smoke, fumes, and fine dust particles, especially when cutting materials like metal. Fume extraction systems or dust collectors are required to remove hazardous materials from the air and keep the environment safe and compliant with health regulations.

- Floor Load and Vibration Control

- The machine should be installed on a stable, vibration-free surface. High-powered machines like the 8000w laser cutting machine can be sensitive to vibrations, which can negatively affect the cutting accuracy and cause wear on the system.

To ensure optimal performance and safety, the 8000w laser cutting machine should be placed in a controlled environment that maintains the proper temperature, humidity, clean air supply, and power stability. Adequate space for operation, proper ventilation, noise management, and safety measures are all essential for long-term operation and maintenance.

4 reviews for 8000W Laser Cutting Machine

Hristo –

Impressed with the quality and precision of this fiber laser cutting machine. It’s a valuable addition to our production process, increasing efficiency.

Mohamed –

Exceptional performance from this laser cutting machine. It’s fast, accurate, and easy to operate, boosting our productivity significantly.

Omondi –

Precision and efficiency define this fiber laser cutting machine. It’s a reliable workhorse in our workshop, delivering consistent, high-quality results.

Sophie –

Dependable and versatile, this laser machine is a game-changer for our business. It’s efficient, reliable, and exceeds our expectations.