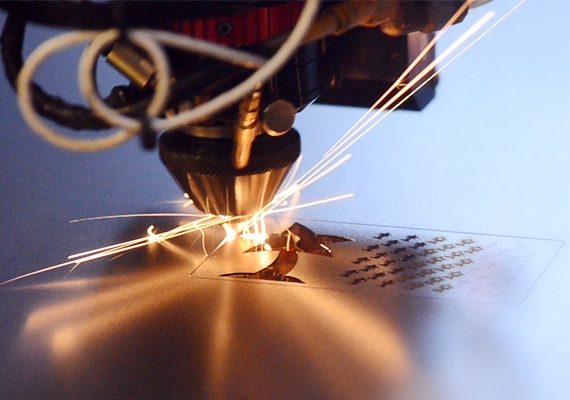

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

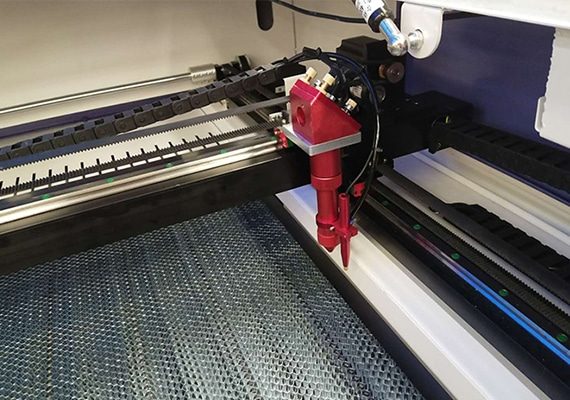

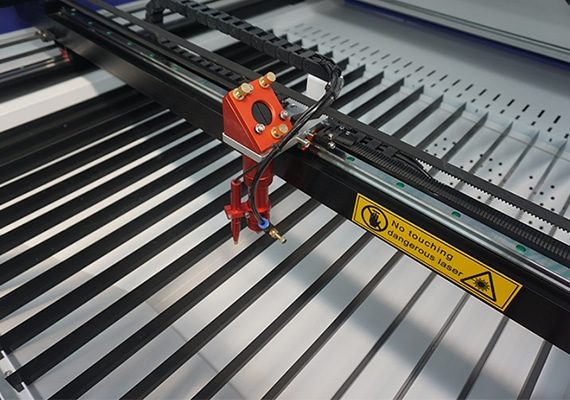

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

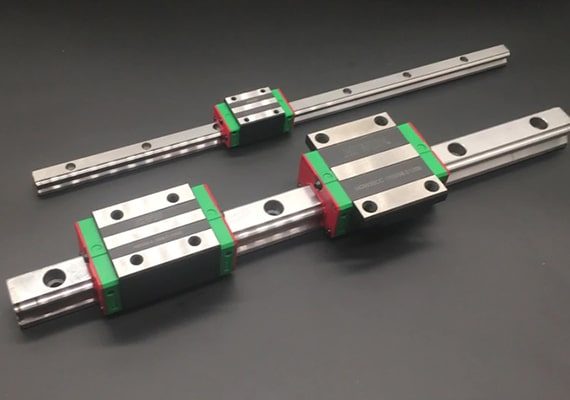

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

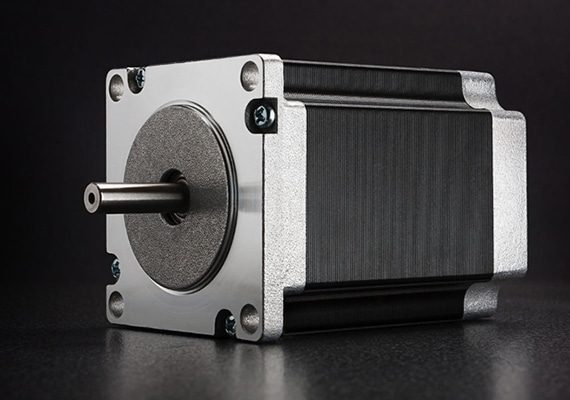

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 3mm | 5mm | 8mm | 10mm | 15mm | 20mm | 25mm | 30mm | 35mm | 40mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 8mm/s | 4mm/s | 1mm/s | / | / | / | / | / | / | / |

| Optimal Cutting Speed | 5mm/s | 2mm/s | / | / | / | / | / | / | / | / | |

| 40W | Max Cutting Speed | 15mm/s | 8mm/s | 4mm/s | 3mm/s | / | / | / | / | / | / |

| Optimal Cutting Speed | 10mm/s | 5mm/s | 2mm/s | / | / | / | / | / | / | / | |

| 60W | Max Cutting Speed | 20mm/s | 10mm/s | 5mm/s | 4mm/s | 2mm/s | 1mm/s | / | / | / | / |

| Optimal Cutting Speed | 15mm/s | 7mm/s | 3mm/s | 2mm/s | 0.8mm/s | 0.3mm/s | / | / | / | / | |

| 80W | Max Cutting Speed | 25mm/s | 12mm/s | 9mm/s | 6mm/s | 3mm/s | 1.5mm/s | 0.5mm/s | / | / | / |

| Optimal Cutting Speed | 20mm/s | 8mm/s | 5mm/s | 3mm/s | 1.5mm/s | 0.5mm/s | 0.2mm.s | / | / | / | |

| 100W | Max Cutting Speed | 30mm/s | 15mm/s | 10mm/s | 7mm/s | 4mm/s | 2mm/s | 0.8mm/s | 0.3mm/s | / | / |

| Optimal Cutting Speed | 25mm/s | 10mm/s | 6mm/s | 4mm/s | 2mm/s | 0.7mm/s | 0.3mm/s | / | / | / | |

| 130W | Max Cutting Speed | 35mm/s | 17mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1mm/s | 0.5mm/s | 0.2mm/s | / |

| Optimal Cutting Speed | 30mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1mm/s | 0.4mm/s | 0.3mm/s | / | / | |

| 150W | Max Cutting Speed | 40mm/s | 21mm/s | 15mm/s | 11mm/s | 7mm/s | 4mm/s | 1.8mm/s | 0.8mm/s | 0.4mm/s | 0.1mm/s |

| Optimal Cutting Speed | 35mm/s | 15mm/s | 10mm/s | 7mm/s | 4mm/s | 1.5mm/s | 0.8mm/s | 0.5mm/s | 0.1mm/s | / | |

| 180W | Max Cutting Speed | 45mm/s | 25mm/s | 18mm/s | 16mm/s | 9mm/s | 5mm/s | 2.5mm/s | 1.3mm/s | 0.6mm/s | 0.2mm/s |

| Optimal Cutting Speed | 40mm/s | 18mm/s | 12mm/s | 10mm/s | 6mm/s | 2mm/s | 1.2mm/s | 0.8mm/s | 0.3mm/s | 0.1mm/s | |

| 200W | Max Cutting Speed | 55mm/s | 30mm/s | 25mm/s | 20mm/s | 11mm/s | 7mm/s | 5mm/s | 3mm/s | 1mm/s | 0.5mm/s |

| Optimal Cutting Speed | 45mm/s | 25mm/s | 15mm/s | 13mm/s | 8mm/s | 4mm/s | 3mm/s | 1.5mm/s | 0.7mm/s | 0.3mm/s |

| Cutting Process | Laser Cutting | CNC Routing | Saw Cutting | Ultrasonic Cutting |

|---|---|---|---|---|

| Precision And Accuracy | High | Good | Moderate | High |

| Cutting Speed | High | Moderate | Low | Moderate |

| Material Thickness | Thin to Medium | Thin to Thick | Thick | Thin to Medium |

| Heat Affected Zone | Minimal | Minimal | Moderate | Minimal |

| Cutting Edge Quality | Smooth and Polished | Smooth | Rough | Smooth and Precise |

| Material Waste | Minimal | Moderate | High | Minimal |

| Complexity | Suitable for Intricate Designs | Suitable for Complex Designs | Simple Cuts Only | Suitable for Complex Designs |

| Versatility | Versatile | Versatile | Limited Applications | Limited Applications |

| Noise | Low | Moderate | High | Low |

| Equipment Cost | High | High | Low | High |

| Operating Cost | Moderate to High | Moderate to High | Low | Moderate to High |

| Safety Considerations | Eye Protection | Eye Protection | Safety Gear | Eye Protection |

| Post-Processing Required | Rarely | Sometimes | Often | Rarely |

| Handling Complex Designs | Yes | No | No | Yes |

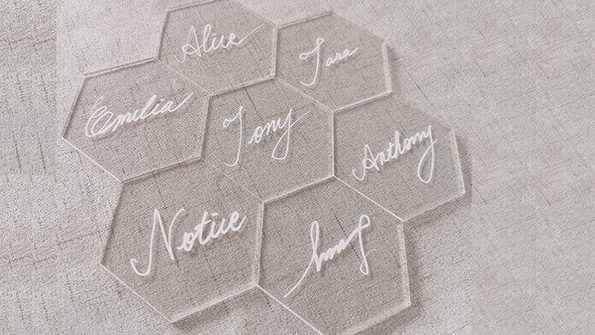

Yes, laser-cutting machines can cut acrylic. Laser cutting is one of the most popular methods of cutting acrylic sheets and other materials. Also known as plexiglass or PMMA (polymethyl methacrylate), acrylic has properties ideal for laser cutting.

The laser cutting process works by using a high-powered laser beam to melt, burn, or vaporize material along the cutting path. A focused laser beam delivers a large amount of energy to a small area, allowing it to cut acrylic with high precision and a minimal heat-affected zone. By adjusting the power, speed, and focus of the laser, different cutting depths and edge finishes can be obtained.

The reason to cut acrylic with a laser cutting machine is that it provides clean, smooth edges without the need for additional finishing processes. The cut edges are polished, perfect for projects that require a high-quality finish. Additionally, laser cutting can achieve intricate and detailed designs on acrylic, making it a popular choice for custom signage, displays, and artistic creations.

When using an acrylic laser cutting machine, the settings must be adjusted correctly to ensure a clean cut. Laser power, speed, and focus should be optimized according to the thickness and type of acrylic used. Fumes and potentially hazardous particles are released during laser cutting and proper ventilation and safety measures should be taken.

The price of an acrylic laser cutting machine will vary widely, depending on several factors such as the brand of the machine, power, size, features, and country of purchase. In general, smaller and lower-powered laser cutting machines designed for hobbyists or small businesses can be more affordable, while larger and higher-powered industrial-grade machines can be expensive.

The basic entry-level desktop laser-cutting machine for a hobbyist or small business can cost between $1,000 and $3,000. These machines usually have lower power (such as 40W to 60W) and a smaller cutting area.

Larger, more powerful industrial-grade laser cutting machines with larger cut sizes and higher laser power (such as 100W to 200W) can cost anywhere from $4,000 to $8,000 or more. Prices can be higher for professional and high-end models with advanced features.

These price ranges are rough estimates and will vary by region, specific seller, and other factors. Additionally, factors such as shipping costs, taxes, and optional add-ons can affect the final price of a machine.

If you are planning to buy an acrylic laser-cutting machine, you can contact us. Our engineers will provide you with specific quotations according to your requirements and budget, and we will also provide you with comprehensive after-sales support, warranty, and training services. Looking forward to working with you!

Laser cutting can cut many types of acrylic, but not all types can be laser cut. Whether acrylic is suitable for laser cutting depends on its composition and additives. Here are some common types of acrylic materials suitable for laser cutting:

When laser cutting acrylic materials, it is important to consider the thickness and ensure that the laser cutting machine has the proper power to effectively cut the selected acrylic type. It is recommended to test on scrap before cutting the final design to fine-tune the settings and achieve the desired result.

Additionally, acrylic emits fumes during the laser cutting process, which may contain dangerous chemicals. Therefore, when using a laser cutting machine to cut acrylic materials, it is necessary to have proper ventilation and ensure that safety measures are in place.

The power required to laser cut acrylic depends on several factors, including the thickness of the acrylic, the type of acrylic, the desired cutting speed, and the capabilities of the CO2 laser-cutting machine being used. Generally speaking, acrylic can be cut with a laser cutting machine with a power range of 30 to 150 watts or more. Here is a rough guide to power levels typically used for cutting acrylic:

While using a higher power setting may increase cutting speed, it also causes more heat to be generated, which may affect the quality of the cut edge. Finding the right balance between laser power and cutting speed helps achieve clean and precise cuts without excessive melting or charring of the material. Also, the laser power itself is not the only factor that determines the quality of the cut, the type of assist gas, the focal length of the lens, and the type of lens used also contribute to the best results.

Optimal laser power settings may also depend on the specific type and quality of acrylic being used. Different manufacturers may have slightly different recipes, which can also affect the laser-cutting process. It is therefore advisable to make some test cuts on scraps of the same acrylic material to determine the best power and cutting speed settings for your particular setup.

Laser-cutting acrylic has many advantages, such as high precision, versatility, and the ability to create intricate designs, but it does have some disadvantages. Here are some of the main disadvantages of laser-cutting acrylic:

Despite these drawbacks, laser-cutting acrylic remains a popular choice because of its precision, versatility, and ability to efficiently create intricate designs. To minimize these disadvantages, it is recommended to use proper laser settings, ensure proper ventilation, and invest in quality equipment and maintenance.

The thickness of acrylic that a laser cutting machine can effectively cut depends on a variety of factors, including the power of the laser generator, the quality of the optics, and the capabilities of the particular machine. In general, laser cutting machines are great for cutting acrylic sheets of a certain thickness, and the maximum thickness may vary.

For thin acrylic sheets (less than 1 mm), clean cuts can be achieved even with low-power lasers. As thickness increases, higher laser power is required to effectively cut the material. Medium-power laser generators (60W to 120W) are suitable for cutting acrylic sheets from 4mm to 8mm thick. Beyond 8 mm, a more powerful laser generator is required, such as 120W to 200W or even higher, depending on the thickness of the material and the required cutting speed.

As the thickness increases, the cutting process becomes more challenging and the laser’s power and speed settings may need to be adjusted. Thick acrylic sheets may require multiple cuts and even a specialized laser cutter to achieve a clean, precise cut. Every laser-cutting machine model has its limitations, and some machines may be better suited for cutting thicker materials than others. It is recommended to check the specifications of the specific laser cutting machine you are using or plan to use to determine its maximum cutting capacity for acrylic and other materials.

Preventing burn marks when laser cutting acrylic requires a combination of correct setup, material preparation, and proper technique. Here are some tips to help minimize or eliminate burn marks during laser cutting:

By carefully implementing these strategies and making adjustments to your laser-cutting process, you can significantly reduce the occurrence of burn marks and achieve clean, high-quality cuts in acrylic. When working with laser cutting equipment, always remember to prioritize safety and work in a well-ventilated area.

Yes, laser-cutting acrylic can produce a noticeable smell. The smell is mainly caused by the fumes and gases released during the cutting process. Acrylic is a thermoplastic material that thermally decomposes when subjected to high temperatures from a laser beam. The process releases fumes consisting of acrylic polymer vapors and may also contain small amounts of formaldehyde, a potentially harmful substance.

Odors produced during laser cutting may vary depending on the acrylic type, thickness, laser power and speed settings, and ventilation of the cutting area. Acrylic sheets with additives or coatings may also smell different when laser cut.

Fume produced during laser cutting can be harmful as it may contain volatile organic compounds (VOCs), acrylic polymer vapors, and other potentially toxic substances. These fumes can irritate the eyes, nose, and throat and may cause discomfort in some individuals. Therefore, proper ventilation and exhaust systems are required when laser cutting acrylic to ensure the safety of the operator and maintain a healthy working environment.

To minimize odors and potential health risks, laser cutting machines must be operated in a well-ventilated area with a proper exhaust system. This effectively removes fumes from the workspace, reducing odors and potential health risks. Using air to assist in blowing away smoke and debris during cutting can also help reduce odors.

When using a laser cutting machine, it is critical to maintain a well-ventilated area, use proper protective equipment such as goggles and a mask, and follow the manufacturer’s guidelines for safely operating the laser cutter. Taking these precautions will help mitigate any potential health risks associated with the odor and fumes produced during laser cutting acrylic.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Acrylic Laser Cutting Machine

Valentina –

Exceptional cutting accuracy from our laser machine. It’s a precise tool that ensures our products meet the highest standards.

Ruth –

Streamlined operations with our CO2 laser cutting machine. Its efficiency and precision have optimized our workflow, saving time and resources.

Hamid –

Highly satisfied with our laser cutter’s performance. It’s reliable, efficient, and contributes to our business’s success.

Oliver –

Our CO2 laser machine is an indispensable tool in our workshop. Its versatility and precision make it essential for our manufacturing processes.