$4,000.00 – $8,700.00

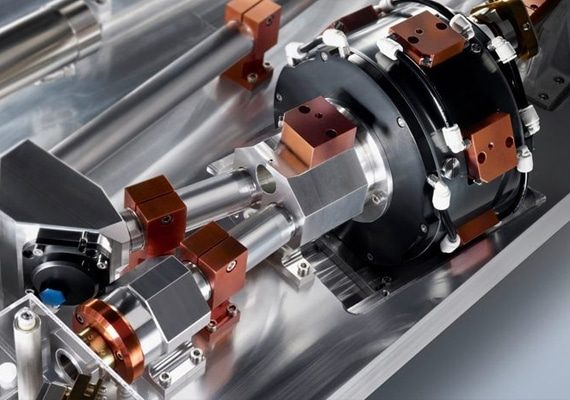

Our laser welding machines are equipped with high-quality laser generators that ensure excellent beam quality, providing small and focused spot sizes for precise and efficient welding. With power output options from 1500w to 3000w, our laser welding machines can meet a variety of welding needs, ensuring optimum productivity without compromising quality.

Designed with reliability in mind, our laser welding machines feature an efficient water cooling system to ensure consistent performance and extend the life of the laser generator. With advanced water cooling technology, we can guarantee stable and reliable welding results even during long-term operation.

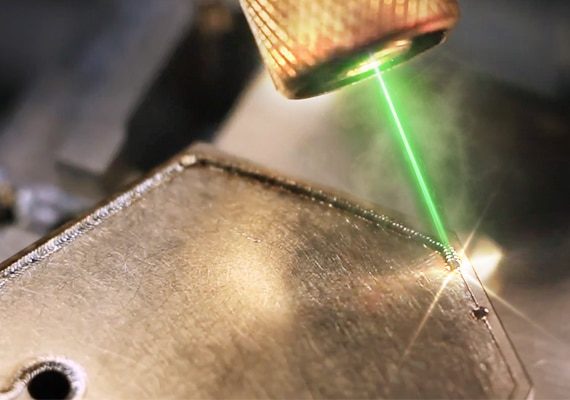

Our laser welding machines have excellent beam quality, producing a focused and precise laser spot. This feature enables high-precision and efficient welding of different materials and thicknesses, reducing spatter and minimizing the heat-affected zone.

The beam delivery system of our laser welding machines utilizes flexible and flexible fiber optic cables, which can be easily integrated into automated production lines or robotic systems, enabling you to flexibly and easily adapt to different welding tasks. This flexibility increases workflow efficiency and seamlessly adapts to various manufacturing settings.

Our laser welding machines feature a user-friendly control interface that gives you complete control over your welding process. Easily adjust and program welding parameters such as power, pulse duration, welding speed, and focus position to obtain the best results for your specific welding requirements.

Our laser welding machines are equipped with comprehensive safety features including enclosures, interlock systems, and safety sensors. These measures protect your operators from potential exposure to the laser beam, creating a safe work environment.

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1080nm | |||

| Way of Working | Continuous/Modulation | |||

| Cooling Method | Water Cooling | |||

| Power Demand | AC220V±5%/50Hz | |||

| Working Environment Temperature | 15~35℃ | |||

| Working Environment Humidity | < 70%(No Condensation) | |||

| Laser Power (W) | Material Type | Welding Form | Thickness (mm) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|---|

| 1000 | 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 35~45 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| 1500 | 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| Butt Welding | 2 | 10~20 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| 1500 | 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| Butt Welding | 2 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| 1500 | 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| Butt Welding | 2 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| Butt Welding | 3 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | ||

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 1.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | ||

| Butt Welding | 2 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Welding Method | Laser Welding | TIG Welding | MIG Welding |

|---|---|---|---|

| Heat Source | High-intensity laser beam | Non-consumable tungsten electrode | Consumable wire electrode |

| Gas Shielding | Generally not required, but can use inert gas | Inert gas (Argon) | Inert gas (Argon) |

| Welding Speed | High speed | Moderate speed | High speed |

| Precision | Very high | High | Moderate |

| Skill Level | Requires high precision and expertise | Requires moderate to high-skill | Relatively easy to learn |

| Weld Quality | High-quality welds, minimal distortion | High-quality welds, low distortion | Good welds, moderate distortion |

| Thickness Range | Thin to medium thicknesses | Thin to thick sections | Thin to thick sections |

| Joint Types | Suited for precision joints | Suited for various joint types | Suited for various joint types |

| Filler Material | Generally not required, but can be used | Requires filler rod | Requires filler wire |

| Welding Cost | Expensive equipment and operation | Moderate equipment and operation cost | Cost-effective |

| Applications | Aerospace, electronics, precision welding | Automotive, general fabrication | General fabrication, construction |

Note: Please note that these characteristics may vary depending on the specific equipment, settings, and expertise of the operator. Welding aluminum can be challenging due to its high thermal conductivity and susceptibility to defects, but with the appropriate welding method and techniques, high-quality aluminum welds can be achieved.

Yes, aluminum can be welded using a laser welding machine. Laser welding is one of the preferred methods of joining aluminum components, especially in industries that require high-precision and clean welding. Laser welding is a versatile welding process that can be used to weld a variety of materials, including metals such as aluminum. When a laser welding machine welds aluminum, it uses a focused laser beam to heat and melt the aluminum surfaces that need to be joined. Laser energy is absorbed by the aluminum, causing rapid heating and localized melting. The laser is then moved along the joint and the molten aluminum fuses together to form a strong weld.

Laser welding produces precise, high-quality welds when welding aluminum. Heat input can be finely controlled during welding, minimizing the risk of deformation or damage to surrounding materials. In addition, laser welding allows precise control of welding parameters, making it possible to weld thin and delicate aluminum parts without distortion.

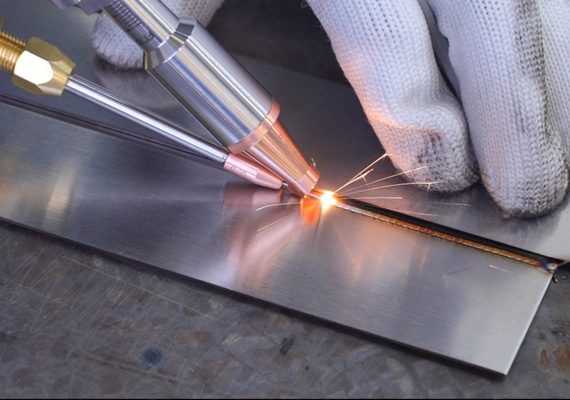

Laser welding is widely used in various industries, including aerospace, automotive, electronics, medical, etc., where aluminum parts require precise and reliable connections. Laser welding is especially valuable in applications where traditional welding methods such as TIG or MIG welding may result in increased distortion or where high-quality welds are difficult to achieve. Laser welding machines provide an effective and efficient solution for welding aluminum, providing excellent weld quality and performance in a wide range of industrial applications.

The maximum thickness of aluminum that a laser welding machine can weld depends on several factors, including laser power, beam quality, welding speed, and specific application requirements. In general, laser welding is well suited for welding thin to medium-thickness aluminum materials. Typical welding thicknesses for aluminum range from about 0.5mm to 3mm for fiber laser generators commonly used to weld metals. However, the advancement of laser technology and the optimization of the welding process may allow thicker aluminum materials to be welded in some special cases.

As the thickness of the material increases, the welding process can become more challenging due to increased heat absorption and heat dissipation from thicker parts of the aluminum. In the case of thicker aluminum, it is still possible to weld with a laser, but higher laser power and slower welding speeds may be required to achieve deep penetration and proper fusion. Additionally, other welding methods such as TIG or MIG welding may be more suitable for thicker aluminum materials due to their higher heat input and deeper penetration capabilities.

The specific requirements of the welding task, joint involvement, and material properties need to be considered when determining the best welding method and the maximum thickness of aluminum that a laser welding machine can effectively handle. Consultation with a welding specialist and feasibility testing are recommended to help ensure successful and reliable results for a particular welding application.

The aluminum most suitable for laser welding is usually an alloy in the 5xxx or 6xxx series. These aluminum alloys are well suited for laser welding due to their composition and properties, which make the welding process more manageable and produce high-quality welds. The following are some aluminum alloy families commonly used for laser welding:

5xxx and 6xxx series aluminum alloys usually contain magnesium as the main alloying element, which contributes to their good welding characteristics. These alloys form solid welds, have a relatively low risk of thermal cracking during laser welding, and have good thermal conductivity to efficiently dissipate heat during welding.

When considering the best aluminum for laser welding, you also need to make sure the aluminum is in the proper tempering condition. Some tempering conditions may have different weldability, so the appropriate temper should be selected according to the specific application and requirements.

When choosing the best aluminum material for laser welding, consider the specific needs of the project, the desired mechanical properties, and the desired weld quality. Consultation with an experienced welding professional can help determine the most suitable aluminum alloy and welding parameters to achieve the best results in your laser welding application.

Laser welding machines offer several advantages when it comes to welding aluminum compared to traditional welding methods such as TIG or MIG welding. Some of these advantages include:

Laser welding machines provide a reliable, efficient solution for welding aluminum with high precision, speed, and quality while minimizing material waste and operating costs.

Managing the heat-affected zone (HAZ) and minimizing deformation are crucial aspects of achieving high-quality aluminum laser welds. Here are some strategies to address these challenges:

By implementing these strategies and techniques, it is possible to effectively manage the heat-affected zone and minimize deformation in aluminum laser welding, resulting in high-quality, distortion-free welds suitable for various industrial applications.

With years of experience in laser welding technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser welding machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser welding machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser welding machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect welds every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser welding machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Aluminum Laser Welding Machine

Maria –

Impressive precision and reliability. Easy setup and operation. Makes welding tasks efficient and effective.

Kamau –

Efficient and powerful. Simplifies complex welding jobs. Essential for our manufacturing process.

Fatima –

Revolutionizes our welding process. Delivers consistent weld quality. A valuable asset for our workshop.

Martin –

Revolutionizes our welding operations. Saves time and resources. Highly recommended for industrial use.