$3,200.00 – $6,400.00

Using well-known brand laser generators (Raycus, JPT, Max, IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better. AccTek Laser can design different configurations to meet customer needs.

AccTek Laser provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the laser welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

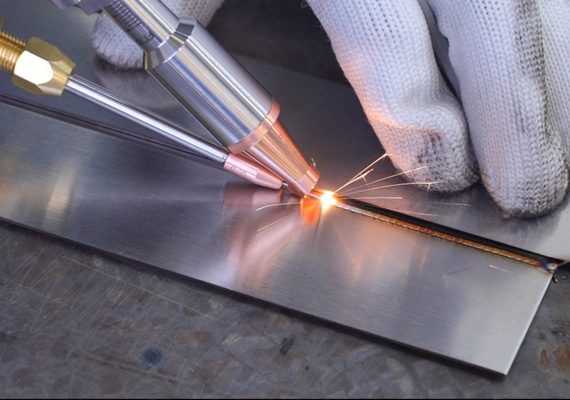

The laser welding head is ergonomically designed, light in shape, comfortable to hold, and easy to control and operate. The hand-held welding head is easy to hold and can be operated at any angle, making welding more convenient and flexible.

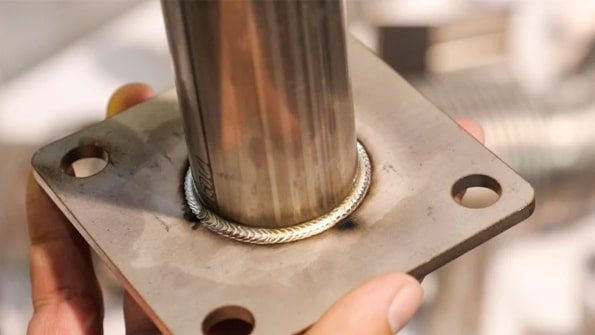

When the gap between the welded metals is greater than 0.2 mm, the welding wire is required during welding. AccTek Laser can add an automatic wire feeder according to customer requirements, and adjust the wire feeding speed through the touch screen. The automatic wire feeder has high repeat wire feeding accuracy, which can avoid the disadvantages of unstable and low efficiency of manual wire feeding.

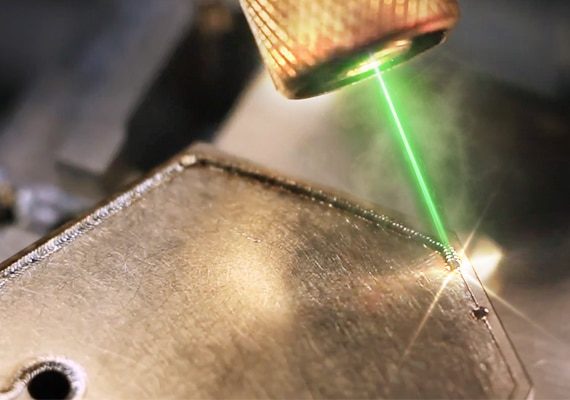

The wobble hand-held laser head is light in shape and economical in design, which provides great convenience for the laser welding process. In addition, we adopt a high-speed digital motor wobble design, which can switch freely between multiple welding modes.

| Model | AKH-1500 | AKH-2000 | AKH-3000 | |

| Laser Power | 1500W | 2000W | 3000W | |

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1080nm | |||

| Way of Working | Continuous/Modulation | |||

| Cooling Method | Water Cooling | |||

| Power Demand | AC220V±5%/50Hz | |||

| Working Environment Temperature | 15~35℃ | |||

| Working Environment Humidity | < 70%(No Condensation) | |||

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Carbon Steel | 0.5-1.5mm | 0.5-2mm | 0.5-3mm | 0.5-5mm |

| Stainless Steel | 0.5-1.5mm | 0.5-2mm | 0.5-3mm | 0.5-5mm |

| Brass | 0.5-1mm | 0.5-1.5mm | 0.5-2mm | 0.5-4mm |

| 1-3 Series Aluminum Alloys | 0.5-1.5mm | 0.5-2mm | 0.5-2mm | 0.5-3mm |

| 4-7 Series Aluminum Alloys | 0.5mm | 0.5-1mm | 0.5-1.5mm | 0.5-2mm |

| Copper | / | 0.5mm | 0.5mm | 0.5-1mm |

Yes, the price listed is the FOB (Free on Board) price. This means the seller covers the cost of getting the goods to the port and loading them onto the ship. From there, the buyer handles all remaining shipping costs and risks to the final destination. Let me know if you have more questions about the shipping terms!

The machine offers three power options: 1500W, 2000W, and 3000W. The 1500W is great for light applications or welding thinner materials. The 2000W can handle a wider range of materials and thicknesses, with moderate welding speeds, making it great for general use in a variety of applications. The 3000W is great for heavy applications, faster processing speeds, and welding thicker materials.

Each power option allows you to choose the one that best fits your specific needs, whether for precision, speed, or handling different material thicknesses. If you have more questions or need help choosing the right power level, feel free to ask!

The laser welding machine is designed to weld a variety of metal materials:

These materials make the machine versatile across industries, from construction to electronics. If you need further details on welding-specific materials, feel free to ask!

Yes, laser welding machines typically require shielding gas. The shielding gas plays an essential role in protecting the weld area from oxidation and contamination during the welding process, ensuring a cleaner and stronger weld. Common gases used are:

The choice of gas depends on the material being welded and the desired weld quality. Shielding gas also helps to control the temperature and stability of the weld, reducing splatter and minimizing the risk of defects.

Yes, wearing protective glasses is essential when using a laser welding machine. Laser welding emits intense light and radiation that can seriously harm your eyes, even from indirect exposure. Protective glasses are specifically designed to block harmful laser wavelengths, preventing eye injuries like burns, retinal damage, and long-term vision issues.

The glasses should match the laser’s wavelength, usually indicated by the laser machine specifications, and meet safety standards. Proper eye protection also enhances overall safety by allowing you to focus on precise welds without risk. In addition to glasses, other protective gear, like gloves and protective clothing, is recommended to ensure complete safety during operation.

Our laser welding machine package includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser welding machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser welding machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

With years of experience in laser welding technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser welding machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser welding machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser welding machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect welds every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser welding machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Automatic Wire Feeder Laser Welding Machine

Ali –

Impressed with its durability and performance. Makes welding tasks effortless. Highly recommended for manufacturing.

Daniela –

Effortlessly handles intricate welds. Saves time and improves efficiency. Essential for our production workflow.

Peter –

The Versatile tool for various materials. Produces strong and durable welds. Highly recommended for industrial applications.

Ioana –

Revolutionizes our welding process. Delivers consistent weld quality. A valuable asset for our workshop.