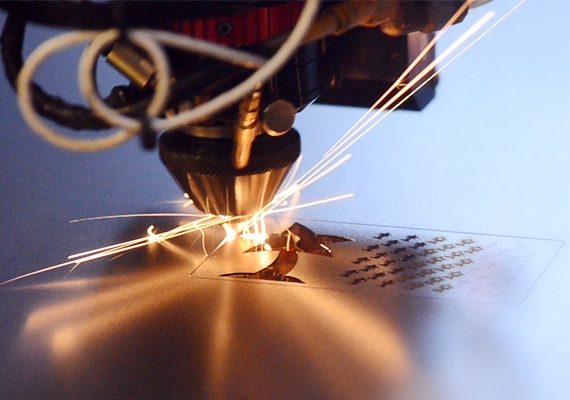

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

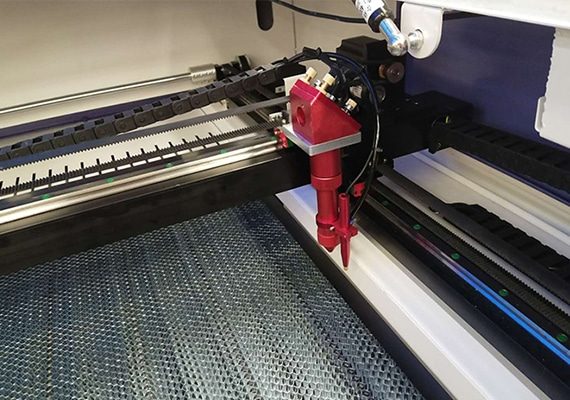

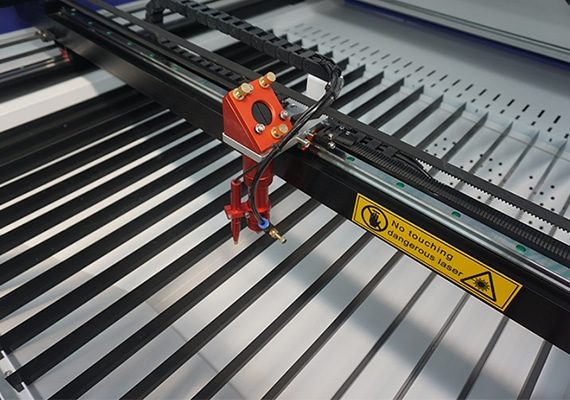

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

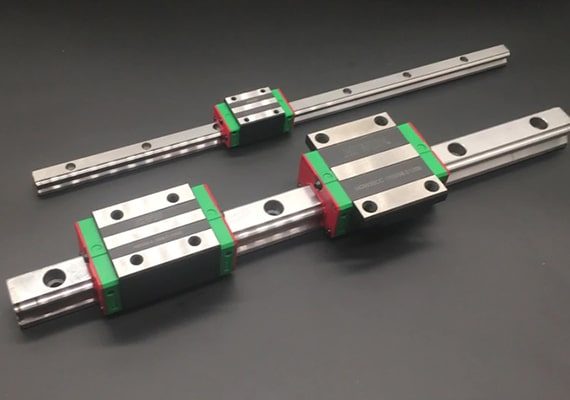

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

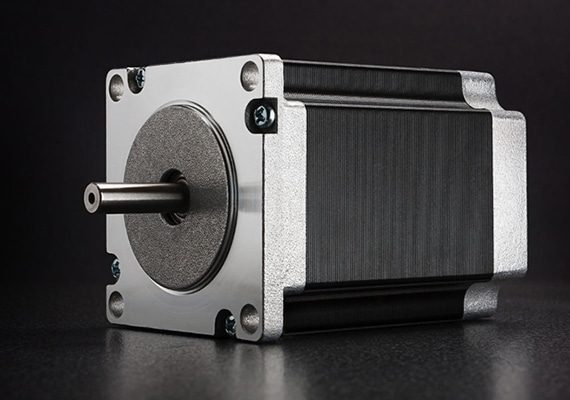

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 3mm | 5mm | 10mm | 15mm |

|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 4mm/s | / | / | / |

| Optimal Cutting Speed | / | / | / | / | |

| 40W | Max Cutting Speed | 10mm/s | 5mm/s | / | / |

| Optimal Cutting Speed | 8mm/s | / | / | / | |

| 60W | Max Cutting Speed | 15mm/s | 10mm/s | 4mm/s | / |

| Optimal Cutting Speed | 12mm/s | 8mm/s | / | / | |

| 80W | Max Cutting Speed | 20mm/s | 15mm/s | 8mm/s | / |

| Optimal Cutting Speed | 18mm/s | 10mm/s | 6mm/s | / | |

| 100W | Max Cutting Speed | 25mm/s | 20mm/s | 12mm/s | 8mm/s |

| Optimal Cutting Speed | 22mm/s | 18mm/s | 10mm/s | 5mm/s | |

| 130W | Max Cutting Speed | 30mm/s | 25mm/s | 15mm/s | 11mm/s |

| Optimal Cutting Speed | 28mm/s | 22mm/s | 13mm/s | 8mm/s | |

| 150W | Max Cutting Speed | 35mm/s | 30mm/s | 20mm/s | 15mm/s |

| Optimal Cutting Speed | 33mm/s | 30mm/s | 20mm/s | 15mm/s | |

| 180W | Max Cutting Speed | 40mm/s | 35mm/s | 25mm/s | 18mm/s |

| Optimal Cutting Speed | 37mm/s | 32mm/s | 20mm/s | 15mm/s | |

| 200W | Max Cutting Speed | 50mm/s | 45mm/s | 35mm/s | 25mm/s |

| Optimal Cutting Speed | 48mm/s | 42mm/s | 30mm/s | 22mm/s |

| Features | Laser Cutting | Band Saw Cutting | Coping Saw Cutting | Scroll Saw Cutting |

|---|---|---|---|---|

| Precision | Very high | High | Moderate | High |

| Cutting Speed | Very fast | Fast | Slow | Moderate |

| Cutting Thickness | Thin to medium | Thin to thick | Thin to medium | Thin to medium |

| Intricate Designs | Excellent | Limited | Limited | Excellent |

| Straight Cuts | Excellent | Excellent | Limited | Good |

| Curved Cuts | Excellent | Limited | Excellent | Excellent |

| Waste Material | Minimal | Moderate | Moderate | Moderate |

| Noise | Low | Moderate | Low | Moderate |

| Material Waste | Minimal | Moderate | Moderate | Moderate |

| Skill Level Required | Advanced | Intermediate | Beginner to Intermediate | Intermediate |

| Heat Generation | Minimal | Minimal | None | Minimal |

| Dust | Minimal | Moderate | Low | Moderate |

| Material Thickness Limit | Thin to Moderate | Thin to Thick | Thin to Moderate | Thin to Thick |

| Safety Gear Required | Safety glasses, ventilation | Safety glasses, dust mask | Safety glasses, dust mask | Safety glasses, dust mask |

Balsa wood is a lightweight, soft, and versatile wood derived from the Balsa tree, scientifically known as Ochroma pyramidale. It is native to the rainforests of Central and South America but is also cultivated in other parts of the world, including Asia and Africa.

Balsa wood is a popular choice for model airplane construction due to its lightweight nature, ease of shaping, and excellent strength-to-weight ratio. It is also used in the creation of prototypes and mock-ups in various industries, including architecture, engineering, and product design. Additionally, balsa wood is employed in crafting for its versatility and ability to be painted, stained, or finished to achieve various decorative effects.

Yes, laser cutting is a very effective method of cutting balsa wood. The laser cutting machine equipped with the appropriate laser generator can easily and accurately cut balsa wood.

When using a laser cutting machine to cut balsa wood, you must choose the appropriate laser settings, such as laser power, cutting speed, and focal length, to obtain the desired results. Additionally, proper ventilation and well-ventilated workspace are crucial to help eliminate any smoke or fumes created during the cutting process.

Laser cutting is a popular choice for balsa wood processing because of its precision, speed, and versatility, making it suitable for a wide range of applications from model making and prototyping to crafts and architectural models.

Yes, laser cutting can produce precise, clean edges on balsa wood. The laser beam is focused to a fine point, allowing it to cut wood with incredible precision. As the beam passes through the material, it vaporizes the wood along the cutting path, creating a sharp edge without any chips or roughness.

Additionally, laser cutting allows excellent control over cutting parameters such as power, speed, and frequency. This control enables the operator to adjust settings to match the specific characteristics of the balsa wood used, ensuring optimal cutting performance and edge quality.

The narrow kerf width produced by laser cutting means minimal material loss and exceptionally clean edges, making it ideal for complex designs and delicate projects. Additionally, post-processing requirements are typically minimal because the heat generated by the laser beam seals the cut edges, leaving a smooth surface finish. Overall, laser cutting is a highly precise and efficient method of producing clean edges in balsa wood, suitable for a wide range of applications including handcrafting, model making, and prototyping.

Laser settings for cutting balsa wood may vary based on several factors, including the type and thickness of the balsa wood, the power of your specific laser cutting machine, and the cutting speed required. However, here are some general guidelines to help you get started laser cutting balsa wood:

Keep in mind that these settings are just general guidelines and the best settings may vary depending on your specific laser cutting machine and the unique characteristics of the balsa wood you are working with. Familiarizing yourself with your laser cutting machine’s capabilities and testing them can help determine the best settings for your specific application. Additionally, always put safety first when operating a laser cutting machine and follow the manufacturer’s guidelines and safety recommendations.

While laser cutting is a versatile and precise method for balsa wood processing, there are some drawbacks and challenges associated with the process. Here are some common disadvantages of laser cutting balsa wood:

Despite these drawbacks, laser cutting remains a popular choice for balsa wood processing due to its precision, speed, and versatility. Many of these issues can be overcome with proper technique, equipment adjustments, and experience. Additionally, advances in laser technology continue to improve the quality of laser-cut balsa wood projects, making it a valuable tool for craftsmen, designers, and model makers.

There are a variety of potential hazards and safety considerations involved when laser cutting balsa wood. However, understanding these risks and taking appropriate precautions can ensure a safe work environment. Here are some potential dangers associated with laser cutting balsa wood:

To mitigate these dangers when laser cutting balsa wood, consider taking the following safety measures:

By understanding and addressing these potential hazards and following safety precautions, you can significantly reduce the risks associated with laser cutting balsa wood and create a safer working environment.

The cost of a balsa wood laser cutting machine can vary greatly based on a variety of factors, including the machine’s size, power, features, brand, and additional features. Here is a rough price range for you to consider, but keep in mind that these prices may change over time and may vary depending on your location:

It’s important to note that in addition to the initial purchase price, there may be additional costs to consider, such as shipping, installation, training, maintenance, and any necessary accessories or software. The choice of laser cutting machine should fit your specific needs and budget. There are some factors you need to consider related to your project, such as the size of the project you will be working on, the material you will be cutting, the accuracy required, and any other features or functionality you require.

If you are planning to purchase a balsa wood laser cutting machine, you can contact us. Our engineers will provide you with a complete balsa wood cutting solution based on your specific needs and budget. Your support is our driving force to move forward!

Yes, the moisture content of balsa wood can affect its laser-cutting performance. Balsa wood is a lightweight, porous material that absorbs moisture from the environment, causing changes in its physical properties. Here are the effects of moisture content on laser cutting:

To mitigate the effects of moisture on laser cutting performance, it is critical to properly prepare balsa wood before cutting. This includes storing the wood in a dry environment to minimize hygroscopicity and acclimate it to the ambient humidity conditions of the cutting environment. Additionally, using proper ventilation and adjusting laser cutting parameters to compensate for moisture levels can help achieve cleaner, more accurate cuts when working with balsa wood.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Balsa Wood Laser Cutting Machine

Jing –

Enhanced precision and efficiency with our laser cutter. It’s a reliable workhorse that streamlines our operations and boosts productivity.

Hassan –

Our laser cutting machine is a game-changer. It’s versatile, efficient, and consistently delivers high-quality results, exceeding our expectations.

Mohamed –

Impressed by the performance and reliability of our laser cutter. It’s a valuable asset that enhances our production capabilities.

Sara –

Dependable cutting solutions from our laser machine. Its reliability and accuracy are unmatched, ensuring flawless results every time.