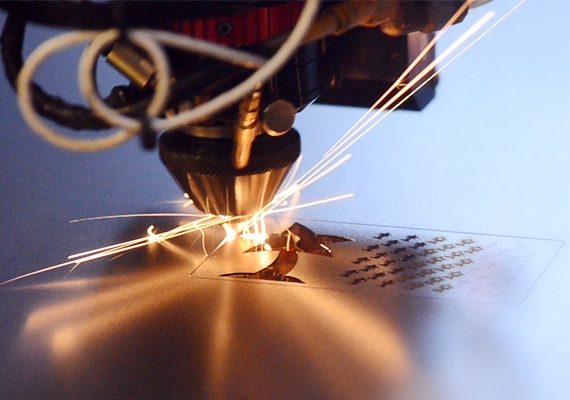

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

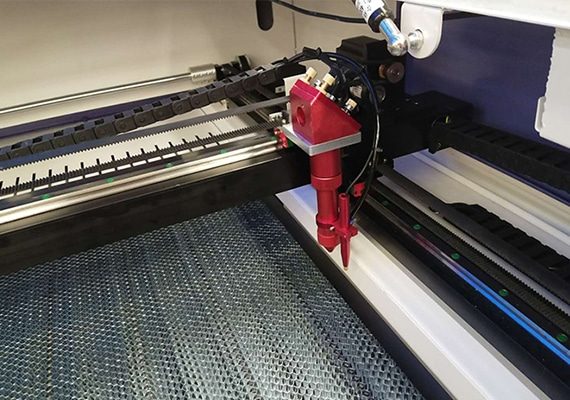

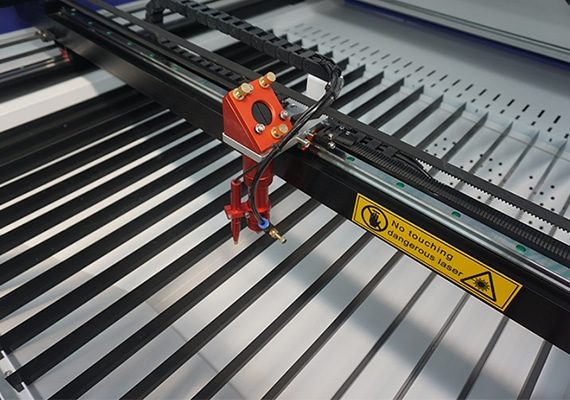

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

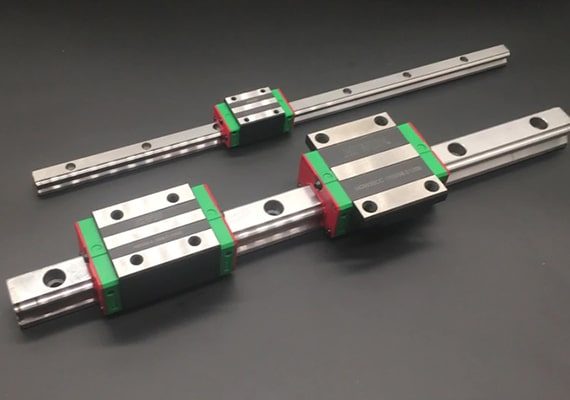

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

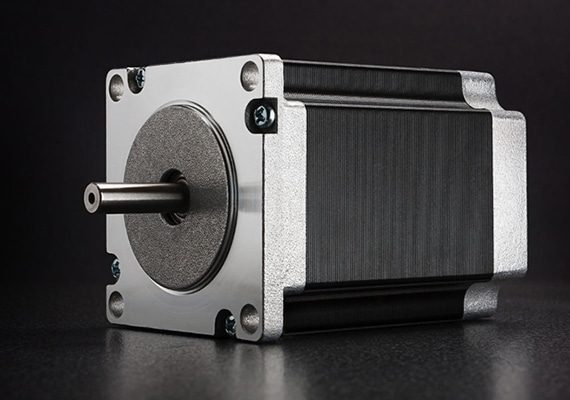

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed (Monolayer) | |

|---|---|---|

| 25W | Max Cutting Speed | 25mm/s |

| Optimal Cutting Speed | 20mm/s | |

| 40W | Max Cutting Speed | 40mm/s |

| Optimal Cutting Speed | 38mm/s | |

| 60W | Max Cutting Speed | 60mm/s |

| Optimal Cutting Speed | 58mm/s | |

| 80W | Max Cutting Speed | 100mm/s |

| Optimal Cutting Speed | 98mm/s | |

| 100W | Max Cutting Speed | 200mm/s |

| Optimal Cutting Speed | 195mm/s | |

| 130W | Max Cutting Speed | 300mm/s |

| Optimal Cutting Speed | 295mm/s | |

| 150W | Max Cutting Speed | 400mm/s |

| Optimal Cutting Speed | 395mm/s | |

| 180W | Max Cutting Speed | 500mm/s |

| Optimal Cutting Speed | 495mm/s | |

| 200W | Max Cutting Speed | 600mm/s |

| Optimal Cutting Speed | 590mm/s | |

| Features | Laser Cutting | Die Cutting | Ultrasonic Cutting | Electric Scissors |

|---|---|---|---|---|

| Cutting Precision | Highly Precise and Detailed Cuts | Precise and Consistent Shapes | Clean and Precise Cuts | Suitable for Simpler Cutting Tasks |

| Cutting Speed | High Cutting Speed | Suitable for Mass Production | Moderate Cutting Speed | Moderate Cutting Speed |

| Material Compatibility | Suitable for a Wide Range of Fabric Types | Suitable for Various Fabric Types | Effective for Synthetic Fabrics | Limited to Simpler Cutting Tasks |

| Fraying and Distortion | Minimal Fraying or Distortion | Minimal Fraying or Distortion | Prevents Fraying of Synthetic Fabrics | May Cause Fraying, Especially on Delicate Fabrics |

| Versatility | Ideal for Intricate Designs and Patterns | Cuts Multiple Layers of Fabric Simultaneously | Ideal for Sportswear and Technical Textiles | Limited Versatility, Best for Straightforward Cuts |

| Production Scale | Suitable for Both Small-Scale and Industrial Use | Ideal for Mass Production | Commonly Used in Industrial Applications | Primarily for Home Sewing and Crafting |

| Additional Processing Needed | Typically No Additional Sealing or Finishing Needed | May Require Additional Sealing or Finishing | Typically No Additional Sealing or Finishing Needed | May Require Additional Sealing or Finishing |

| Energy Source | Requires Electricity and a Laser Source | Requires a Mechanical Press and Dies | Requires Electricity | Requires Electricity |

| Automation | Often Fully Automated | Can Be Automated for Production | Manual Operation | Manual Operation |

| Set-Up Time | Requires Initial Set-Up | Requires Die Creation/Setup | Quick Setup, No Dies Needed | Minimal Setup |

| Maintenance | Regular Maintenance Required | Die Maintenance Needed | Minimal Maintenance | Minimal Maintenance |

| Special Considerations | Eye Protection Needed Due to Laser | Requires Die Creation | May Require Specific Fabric Types | Suitable for Simpler Tasks |

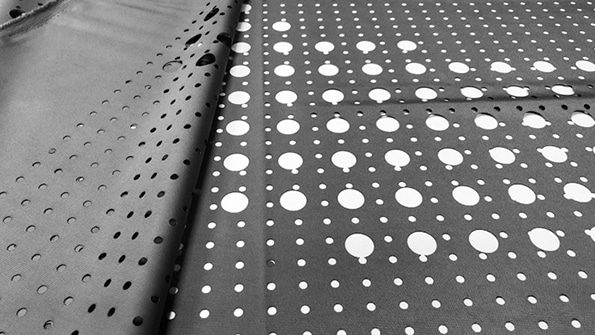

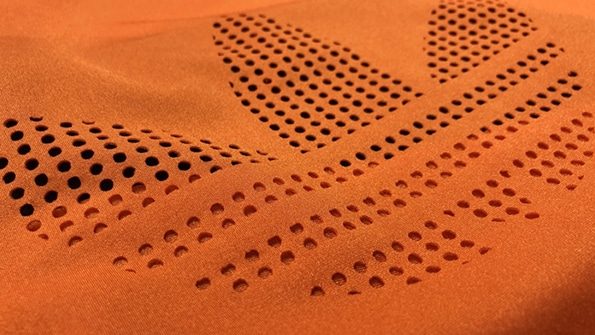

Yes, you can use a laser cutting machine to cut fabric. Fabric laser-cutting machines are specifically designed for this purpose and are widely used in the textile and clothing industries. It uses a focused CO2 laser beam to heat and vaporize fabric along a specific path, resulting in clean, accurate cuts.

The fabric laser cutting machines are versatile and can cut a wide range of fabrics, including natural fibers like cotton and silk, synthetic materials like polyester and nylon, and even more complex textiles like leather and felt. It excels at creating complex designs, patterns, and shapes, making it a valuable tool in industries that require precision and customization, such as apparel manufacturing, interior decoration, and fashion design.

However, safety precautions must be taken when using a fabric laser-cutting machine. Operators should wear appropriate protective equipment, such as laser safety glasses, to protect their eyes from laser radiation. Additionally, appropriate ventilation and exhaust systems should be installed to eliminate fumes generated during cutting.

The cost of a fabric laser cutting machine can vary greatly depending on a variety of factors, including the machine’s brand, model, size, features, and additional features. Here are some general price ranges for fabric laser-cutting machines to help you know what to expect:

It’s important to note that these are approximate price ranges only, and actual prices may vary based on factors such as machine specifications, supplier or manufacturer, geographic location, and any other accessories or support packages that come with the machine. Additionally, the initial purchase cost is only one aspect of the total cost of ownership, and you should also consider ongoing expenses such as maintenance, electricity, and laser consumables like lenses and mirrors.

When considering purchasing a fabric laser-cutting machine, it is important to evaluate your specific needs, throughput, and budget. It is recommended to thoroughly research the features and functionality of the machine to ensure it meets your requirements. Additionally, consider factors like warranty and customer support when making your decision.

Laser-cutting fabric can be considered a sustainable option in many ways compared to traditional cutting methods, but this also depends on various factors and how the technology is used. Here are a few things to consider when assessing the sustainability of laser-cut fabrics:

While laser-cutting fabrics offer sustainability advantages, other factors that may affect the overall sustainability of the production process must be considered:

Laser-cutting fabric may be a more sustainable option compared to some traditional cutting methods because it reduces material waste, increases energy efficiency potential, and reduces chemical use. But to maximize sustainability, factors such as energy, machine maintenance, and the selection of sustainable materials must be considered. Furthermore, sustainability is a multifaceted concept involving environmental, social, and economic aspects, thus requiring a holistic approach to assess the overall impact of laser cutting in a specific context.

While CO laser cutting is a highly versatile and accurate method of cutting fabric, it does have some drawbacks and limitations that need to be considered:

Despite these drawbacks, CO2 laser cutting remains a popular choice for fabric cutting due to its high precision, versatility, and ability to handle a variety of fabric types. Many limitations can be solved or minimized with appropriate equipment, settings, and techniques. Evaluating your specific needs and understanding the characteristics of the fabric you are working with can help determine whether CO2 laser cutting is the right choice for your application.

Laser cutting can be used on a variety of fabrics, but certain materials are better suited to this cutting method due to their compatibility with laser technology. Fabrics best suited for laser cutting usually have certain properties that make the cutting process more efficient and produce clean, precise results. Here are some fabrics that are great for laser cutting:

While these fabrics are generally suitable for laser cutting, specific settings, power levels, and cutting speeds may need to be adjusted based on the thickness and composition of the material. Additionally, safety measures and proper ventilation must be considered when using a laser to cut fabric, as fumes may be generated during the cutting process. Ultimately, the choice of laser-cut fabric depends on the intended application and design requirements. Test cutting a sample material can help determine the best settings to achieve the desired results.

Laser-cutting fabric is safe if proper precautions and safety measures are taken. But like any tool or process, laser cutting has potential risks that should be managed to minimize the risks associated with using a laser cutting machine. Here are some considerations for using a laser-cutting machine on fabric:

By following these safety precautions and guidelines, you can safely cut fabric with a laser cutting machine. It is recommended to consult the manufacturer of your laser cutting equipment for specific safety advice, as requirements may vary depending on the design and capabilities of the machine. Additionally, local regulations and safety standards should always be followed when operating a laser-cutting machine.

Several factors affect the speed and efficiency of laser-cutting fabric:

By carefully considering and optimizing these factors, manufacturers can achieve faster and more efficient laser cutting of fabrics, thereby increasing the productivity and quality of fabric-based production processes.

Safety is critical when laser cutting fabrics due to the potential for fire hazards and exposure to harmful fumes. Here are some basic security measures to consider:

By implementing these safety measures, operators can minimize the risks associated with laser cutting fabrics and create a safer work environment for themselves and others nearby.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Fabric Laser Cutting Machine

Lejla –

Dependable performance from laser cutter. Its efficiency and accuracy have streamlined our production process, boosting our overall productivity.

Paul –

Exceptional cutting precision from laser machine. It’s a reliable tool that consistently delivers clean, accurate cuts, enhancing our product quality.

Liam –

Our laser cutting machine has exceeded our expectations. It’s efficient, and versatile, and has become an integral part of our manufacturing process.

Michael –

Impressed by the durability and performance of CO2 laser cutter. It’s a reliable solution that ensures consistent, high-quality cuts.