$3,200.00 – $6,400.00

Raycus laser delivers high beam quality and consistent output power for effective surface cleaning. AccTek laser cleaning machine offer various power options to meet diverse cleaning requirements, from rust and paint removal to surface preparation.

AccTek provides high-performance, intuitive, and easy-to-use operating systems. This system allows users to effortlessly adjust settings, monitor performance, and ensure consistent cleaning results, making operation straightforward and reliable. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

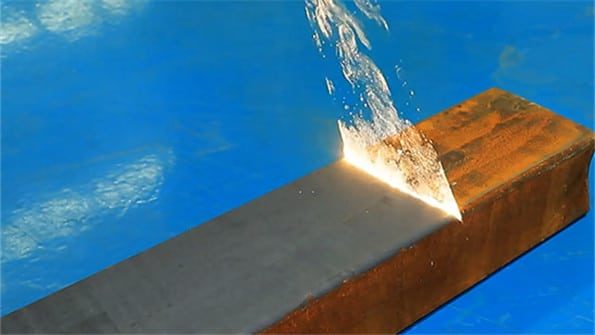

Using a handheld laser cleaning gun design, it can flexibly respond to various objects and angles. Easy to operate and portable move. The beam emitted by the laser cleaning gun can achieve precise positioning and precise cleaning without affecting other surrounding areas. The length of the connecting cable between the laser rust removal gun and the machine is up to ten meters, and a wide range of metal cleaning work can be completed without frequently moving the machine.

| Model | AKQ-1500 | AKQ-2000 | AKQ-3000 |

| Laser Power | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | ||

| Laser Generator | Raycus, Max, BWT | ||

| Pulse Formation | Q-Switched (Quality Factor) | ||

| Cleaning Efficiency | 12㎡/h | ||

| Scanning Width | 10-80mm | ||

| Expected Focal Distance | 160mm | ||

| Fiber Cable Length | 10m | ||

| Cooling Type | Water Cooling | ||

Yes, the price listed is the FOB (Free on Board) price. This means the price covers everything until the product is loaded onto the shipping vessel at the port. After that, the buyer handles all shipping, insurance, and import fees.

The machine offers several power options to suit different cleaning needs. You can choose between 1500W, 2000W, and 3000W models. The 1500W option is ideal for lighter cleaning tasks or materials that require a gentler approach. The 2000W model provides a stronger cleaning power, making it suitable for medium-duty applications where efficiency and speed are important. The 3000W option offers the highest power, allowing for the most intensive cleaning jobs, and effectively removing heavy rust, coatings, or contaminants from durable surfaces. Each option lets you select the right balance of power, speed, and cleaning intensity based on your specific requirements.

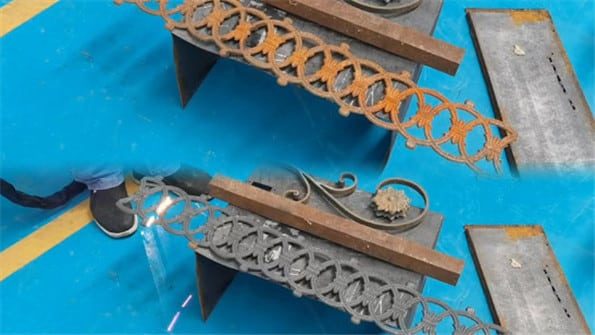

The laser cleaning machine is highly versatile and can clean a wide range of materials. It’s ideal for metals such as steel, aluminum, copper, and brass, effectively removing rust, oxidation, paint, and other contaminants without damaging the base material. It’s also suitable for delicate surfaces like stainless steel, providing a non-abrasive cleaning method that preserves the material’s integrity.

Beyond metals, the laser cleaning machine can work on stone, removing dirt, grime, or paint layers from historical artifacts or statues. It can also clean ceramic surfaces and some types of plastics, depending on their heat sensitivity. This flexibility makes the machine valuable across industries, from manufacturing and automotive to restoration and conservation, where a precise, contactless cleaning process is required.

Our laser cleaning machine offers several cleaning width options to meet different cleaning needs. The standard cleaning width is 270mm, which is ideal for general cleaning tasks and provides efficient coverage. For larger surfaces, you have the option to choose a wider 450mm or 600mm cleaning width, allowing for faster cleaning of bigger areas.

If you require double wobble cleaning for enhanced precision or to cover specific areas, additional options are available. With a double wobble, you can choose from 100x100mm, 130x130mm, 150x150mm, 180x180mm, or 290x290mm, offering a range of sizes for detailed, controlled cleaning. These choices provide flexibility to adapt the machine’s cleaning width to match various tasks and surface areas, ensuring optimal cleaning performance.

Yes, wearing protective glasses is required when using the laser cleaning machine. The laser emits high-intensity light, which can be harmful to your eyes if directly exposed, even from reflected surfaces. Protective laser safety glasses are specifically designed to filter out the laser’s wavelength, providing essential protection to prevent eye damage.

In addition to eye safety, wearing protective glasses is a key part of safe operating practices when working with laser equipment. Even with the machine’s built-in safety features, taking this precaution ensures a safer work environment, particularly in industrial or high-use settings. Always ensure that the protective glasses match the specific wavelength of the laser being used for optimal protection.

Our laser cleaning machine package includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser cleaning machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser cleaning machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

With years of experience in laser cleaning technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser cleaning machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser cleaning machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser cleaning machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cleans every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser cleaning machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Laser Rust Removal Machine

Layla –

Impressive cleaning power, consistent results. Boosts productivity and extends equipment lifespan. Makes tough jobs easy.

Aiden –

Effortlessly removes residues and coatings. Enhances safety and efficiency in the workplace. Compact design, powerful cleaning capability.

James –

Highly impressed with its precision and reliability. Greatly reduces downtime and improves workflow. Essential for industrial maintenance.

Linda –

Efficient and user-friendly interface. Simplifies surface preparation and maintenance tasks. Highly recommended for workshops and production lines.