The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

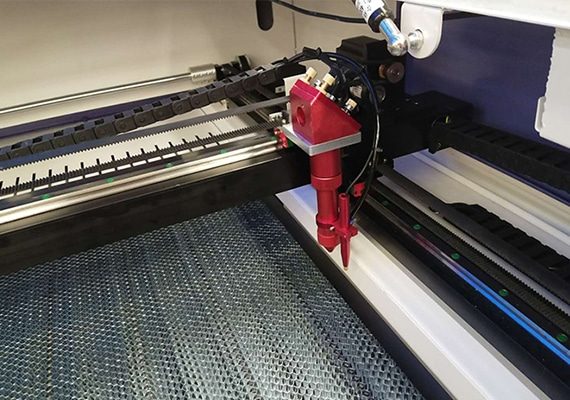

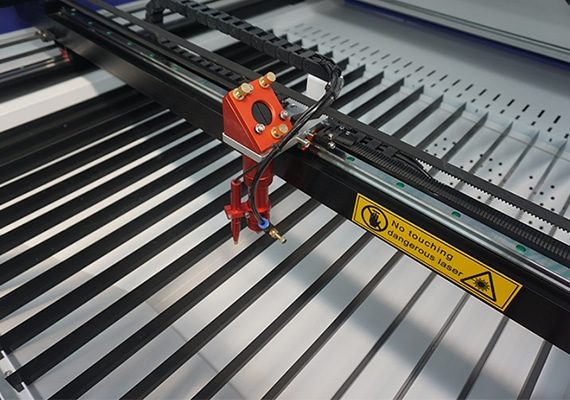

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

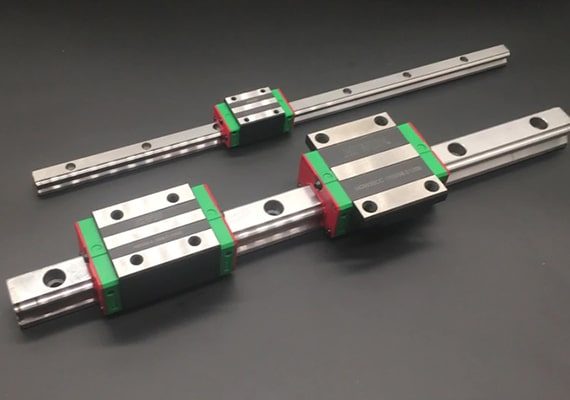

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

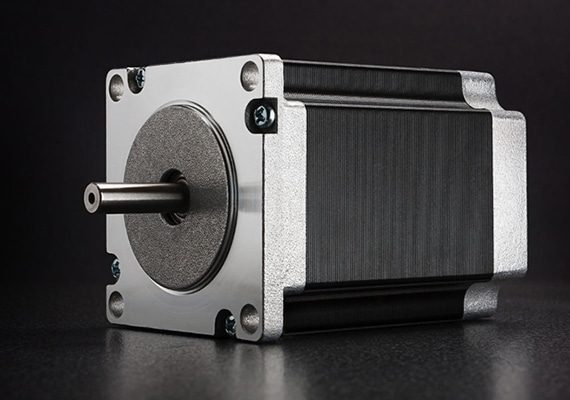

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

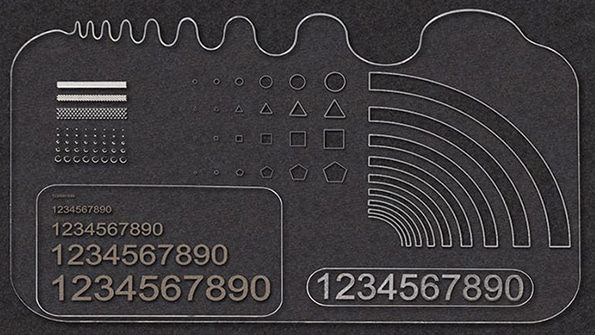

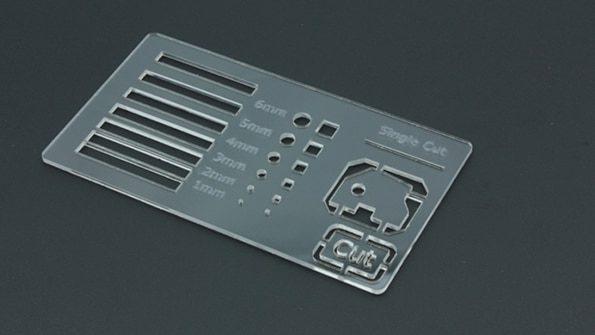

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 3mm | 5mm | 8mm | 10mm | 15mm | 20mm |

|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 30mm/s | 15mm/s | 8mm/s | 5mm/s | 3mm/s | 2mm/s |

| Optimal Cutting Speed | 20mm/s | 10mm/s | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | |

| 40W | Max Cutting Speed | 45mm/s | 25mm/s | 15mm/s | 10mm/s | 6mm/s | 4mm/s |

| Optimal Cutting Speed | 30mm/s | 15mm/s | 10mm/s | 7mm/s | 4mm/s | 3mm/s | |

| 60W | Max Cutting Speed | 60mm/s | 35mm/s | 20mm/s | 15mm/s | 9mm/s | 6mm/s |

| Optimal Cutting Speed | 40mm/s | 20mm/s | 15mm/s | 10mm/s | 6mm/s | 4mm/s | |

| 80W | Max Cutting Speed | 80mm/s | 45mm/s | 25mm/s | 18mm/s | 12mm/s | 8mm/s |

| Optimal Cutting Speed | 50mm/s | 30mm/s | 20mm/s | 12mm/s | 8mm/s | 6mm/s | |

| 100W | Max Cutting Speed | 100mm/s | 60mm/s | 35mm/s | 25mm/s | 15mm/s | 10mm/s |

| Optimal Cutting Speed | 60mm/s | 40mm/s | 25mm/s | 18mm/s | 10mm/s | 8mm/s | |

| 130W | Max Cutting Speed | 130mm/s | 80mm/s | 45mm/s | 30mm/s | 18mm/s | 12mm/s |

| Optimal Cutting Speed | 80mm/s | 50mm/s | 30mm/s | 20mm/s | 12mm/s | 10mm/s | |

| 150W | Max Cutting Speed | 150mm/s | 90mm/s | 50mm/s | 35mm/s | 20mm/s | 15mm/s |

| Optimal Cutting Speed | 90mm/s | 60mm/s | 35mm/s | 25mm/s | 15mm/s | 12mm/s | |

| 180W | Max Cutting Speed | 180mm/s | 110mm/s | 60mm/s | 45mm/s | 25mm/s | 18mm/s |

| Optimal Cutting Speed | 110mm/s | 70mm/s | 40mm/s | 30mm/s | 20mm/s | 15mm/s | |

| 200W | Max Cutting Speed | 200mm/s | 120mm/s | 65mm/s | 50mm/s | 30mm/s | 22mm/s |

| Optimal Cutting Speed | 120mm/s | 80mm/s | 45mm/s | 35mm/s | 25mm/s | 18mm/s |

| Features | Laser Cutting | CNC Routing | Waterjet Cutting | Die Cutting |

|---|---|---|---|---|

| Cutting Speed | High | Moderate to High | Moderate to High | Moderate |

| Precision | Very High | High | High | High |

| Material Thickness Range | Thin to Medium | Thin to Thick | Thin to Thick | Thin to Medium |

| Kerf Width | Very Narrow | Moderate | Moderate | Moderate |

| Material Waste | Minimal | Moderate | Minimal | Moderate |

| Material Types | Versatile | Versatile | Versatile | Limited to Paper, Cardboard, etc. |

| Heat Generation | Generates heat | Minimal heat | Minimal heat | No heat |

| Edge Quality | Very Smooth | Smooth | Smooth | Smooth |

| Tooling or Bit Required | No | Yes | No | Yes |

| Intricate Designs | Yes | Yes | Yes | Yes |

| Maintenance | Low | Moderate | Low | Low |

| Cost | Moderate to High | Moderate | Moderate to High | Low to Moderate |

Yes, lasers can cut PET materials. PET is a common thermoplastic polymer widely used in various industries such as packaging, textiles, and electronics. Laser-cutting PET allows for clean, precise cuts, making it suitable for creating complex designs.

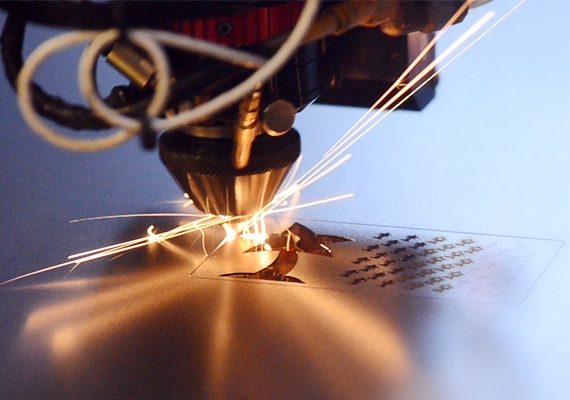

Laser cutting works by focusing a high-power laser beam onto the surface of the material. The laser energy heats materials to the point of melting or vaporizing, allowing for controlled and precise cuts. When cutting PET, factors such as laser power, cutting speed, and focus depth need to be considered to achieve the desired cutting results without causing excessive melting or burning.

The PET is generally considered relatively easy to laser cut due to its relatively low melting point and thermal conductivity. But when laser cutting PET, it needs to be adjusted according to the thickness and type of PET material being cut. Additionally, laser cutting PET may produce some fumes and odors, so proper ventilation and safety precautions need to be taken.

Yes, PET does tend to expand when heated. Like many thermoplastics, PET becomes more malleable when exposed to higher temperatures. This expansion occurs due to the increase in molecular motion and kinetic energy within the material’s structure.

PET has a relatively high glass transition temperature, which is the temperature at which the material changes from a rigid and brittle state to a more flexible and elastic state. When the temperature rises above the glass transition temperature, the molecular chains in PET become more mobile, causing expansion.

While PET does expand when heated, it does not warp or twist as easily as other plastics. PET is commonly used in applications where its thermal properties are a concern, such as plastic bottles and packaging materials. When using PET in applications such as laser cutting or other processes designed to be heated, its thermal expansion characteristics need to be understood to ensure accurate and precise cutting results.

Yes, laser-cutting PET can potentially cause thermal damage to the material, especially if the laser power and speed settings are not properly calibrated. Excessive heat generated during the cutting process can lead to melting, charring, or discoloration of the PET, particularly along the edges of the cut. However, with precise control of laser parameters and appropriate techniques, such as using a focused beam and optimizing cutting speeds, it’s possible to minimize thermal damage and achieve clean, precise cuts. Additionally, cooling systems or air-assist mechanisms can be employed to help dissipate heat and reduce the risk of thermal damage during laser cutting.

Laser-cutting PET is safe if proper precautions are taken. PET is commonly used in a variety of applications, including packaging, textiles, and engineering plastics. When laser cutting PET, you need to consider the following factors:

Before laser cutting PET or any other material, you need to be familiar with the specific properties of the material, the capabilities of your CO2 laser-cutting machine, and the safety guidelines provided by the equipment manufacturer. Additionally, conducting a risk assessment and implementing appropriate safety measures will help ensure the safe use of laser-cutting technology on PET or any other material.

Laser cutting is a versatile and precise method for cutting a variety of materials, but it does have some disadvantages when cutting PET and similar plastics:

Despite these drawbacks, laser cutting remains a viable option for cutting PET materials, especially when the advantages of precision, intricate designs, and minimal tool wear are critical. However, when choosing a cutting method, careful consideration must be given to the characteristics of the material and the specific requirements of the project.

When laser cutting PET, several important considerations and issues need to be addressed to ensure a successful and safe cutting operation. Here are some important considerations:

By addressing these considerations and questions, you can optimize your laser-cutting process for PET materials and achieve the desired results while maintaining safety and quality standards.

Although lasers can cut PET, laser processing performance is affected by PET characteristics. The following are some key material properties of PET materials that affect laser processing performance:

Considering these material properties when working with PET allows you to make informed decisions about laser parameters, process optimization, and safety measures. Testing and experimenting with samples of the specific PET material you are using will help determine the most appropriate laser settings to achieve the desired results while minimizing potential problems.

Additives in PET can significantly affect its laser-cutting performance. The presence of additives, such as colorants, flame retardants, stabilizers, or fillers, can alter the material’s optical properties, thermal conductivity, and absorption characteristics. Consequently, these additives may influence the efficiency, quality, and precision of laser cutting. Here are a few ways additives can impact laser cutting performance:

Understanding the specific additives present in the PET material is crucial for optimizing laser cutting parameters and achieving desired cutting outcomes. Experimentation and testing may be necessary to determine the most suitable laser settings and techniques for cutting PET with additives effectively. Additionally, manufacturers may provide guidelines or recommendations for laser cutting their specific PET formulations.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for PET Laser Cutting Machine

Grace –

Exceptional value for our investment. Our CO2 laser cutting machine delivers superior results, proving to be a worthwhile addition to our workshop.

Finn –

Consistently impressed by laser machine’s capabilities. It’s a versatile tool that adapts to various materials and thicknesses effortlessly.

Sota –

Enhanced precision and efficiency with CO2 laser cutter. It’s a reliable workhorse that streamlines our operations and boosts productivity.

Martin –

Dependable cutting solutions from CO2 laser machine. Its reliability and accuracy are unmatched, ensuring flawless results every time.