$2,700.00 – $8,000.00

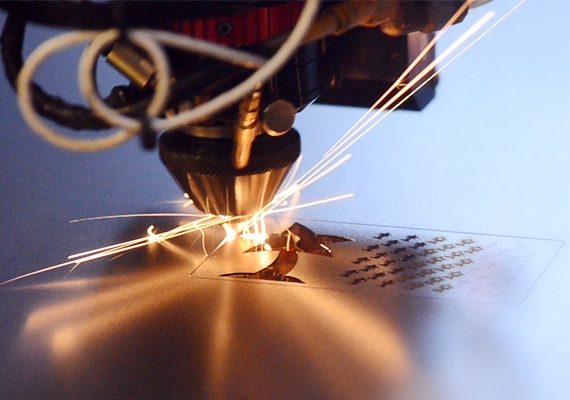

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

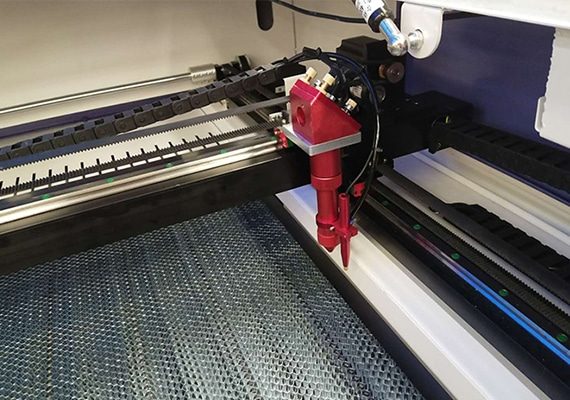

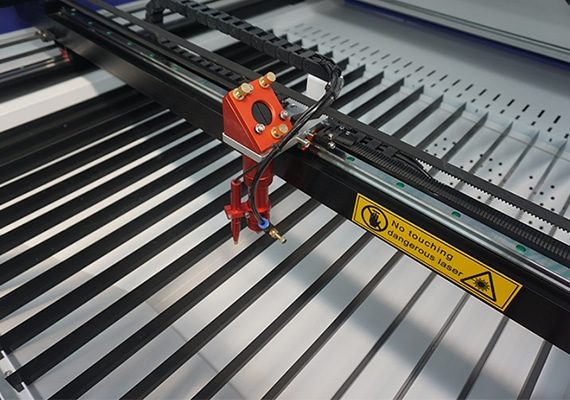

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

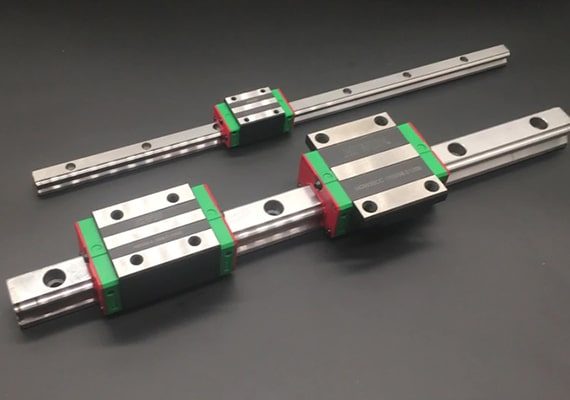

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

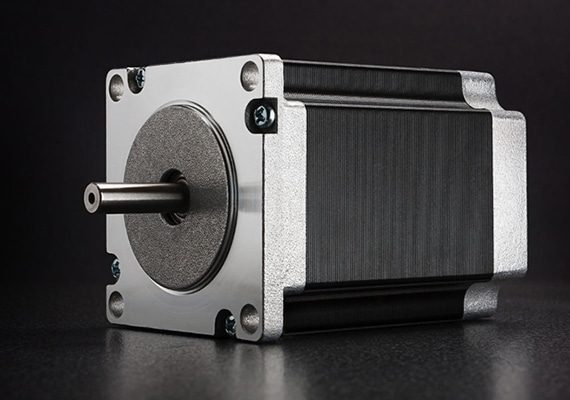

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 3mm | 5mm | 8mm | 10mm | 15mm | 20mm |

|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 20~40mm/s | 10~20mm/s | 5~10mm/s | 3~6mm/s | 1~3mm/s | 0.5~1mm/s |

| Optimal Cutting Speed | 10~20mm/s | 5~10mm/s | 2~5mm/s | 1~3mm/s | 0.5~1mm/s | 0.2~0.5mm/s | |

| 40W | Max Cutting Speed | 40~60mm/s | 20~40mm/s | 10~20mm/s | 6~12mm/s | 2~4mm/s | 1~2mm/s |

| Optimal Cutting Speed | 20~40mm/s | 10~20mm/s | 5~10mm/s | 3~6mm/s | 1~2mm/s | 0.5~1mm/s | |

| 60W | Max Cutting Speed | 60~80mm/s | 30~60mm/s | 15~30mm/s | 9~18mm/s | 3~6mm/s | 1.5~3mm/s |

| Optimal Cutting Speed | 30~60mm/s | 15~30mm/s | 7~15mm/s | 4.5~9mm/s | 1.5~3mm/s | 0.7~1.5mm/s | |

| 80W | Max Cutting Speed | 80~100mm/s | 40~80mm/s | 20~40mm/s | 12~24mm/s | 4~8mm/s | 2~4mm/s |

| Optimal Cutting Speed | 40~80mm/s | 20~40mm/s | 10~20mm/s | 6~12mm/s | 2~4mm/s | 1~2mm/s | |

| 100W | Max Cutting Speed | 100~120mm/s | 50~100mm/s | 25~50mm/s | 15~30mm/s | 5~10mm/s | 2.5~5mm/s |

| Optimal Cutting Speed | 50~100mm/s | 25~50mm/s | 12~25mm/s | 7.5~15mm/s | 2.5~5mm/s | 1.2~2.5mm/s | |

| 130W | Max Cutting Speed | 130~150mm/s | 65~130mm/s | 32.5~65mm/s | 19.5~39mm/s | 6.5~13mm/s | 3.25~6.5mm/s |

| Optimal Cutting Speed | 65~130mm/s | 32.5~65mm/s | 16~32.5mm/s | 9.75~19.5mm/s | 3.25~6.5mm/s | 1.6~3.25mm/s | |

| 150W | Max Cutting Speed | 150~180mm/s | 75~150mm/s | 37.5~75mm/s | 22.5~45mm/s | 7.5~15mm/s | 3.75~7.5mm/s |

| Optimal Cutting Speed | 75~150mm/s | 37.5~75mm/s | 18.75~37.5mm/s | 11.25~22.5mm/s | 3.75~7.5mm/s | 1.87~3.75mm/s | |

| 180W | Max Cutting Speed | 180~220mm/s | 90~180mm/s | 45~90mm/s | 27~54mm/s | 9~18mm/s | 4.5~9mm/s |

| Optimal Cutting Speed | 90~180mm/s | 45~90mm/s | 22.5~45mm/s | 13.5~27mm/s | 4.5~9mm/s | 2.25~4.5mm/s | |

| 200W | Max Cutting Speed | 200~240mm/s | 100~200mm/s | 50~100mm/s | 30~60mm/s | 10~20mm/s | 5~10mm/s |

| Optimal Cutting Speed | 100~200mm/s | 50~100mm/s | 25~50mm/s | 15~30mm/s | 5~10mm/s | 2.5~5mm/s |

| Features | Laser Cutting | CNC Routing | Hot Wire Cutting | Knife Cutting |

|---|---|---|---|---|

| Cutting Precision | High precision | High precision | Moderate precision | Moderate precision |

| Material Versatility | Works with various materials, including polystyrene | Can cut various materials, including polystyrene | Primarily used for polystyrene | Primarily used for polystyrene |

| Cutting Speed | High speed | Moderate speed | Moderate speed | Moderate speed |

| Edge Quality | High-quality, clean edges | High-quality edges | Smooth edges | Smooth edges |

| Complex Shapes | Can cut intricate shapes | Can cut intricate shapes | Limited complex shapes | Limited complex shapes |

| Heat Generation | Generates heat, may melt or distort thin polystyrene | Generates heat, may melt or distort thin polystyrene | Minimal heat generation | Minimal heat generation |

| Material Thickness | Suitable for thin to thick polystyrene sheets | Suitable for thin to thick polystyrene sheets | Suitable for thin to moderate thickness | Suitable for thin to moderate thickness |

| Ventilation/Extraction | Requires ventilation to remove fumes and particles | May produce dust and chips requiring extraction | Minimal emissions, but some fumes may be produced | Minimal emissions, but some dust may be produced |

| Maintenance | Laser tube replacement and optics maintenance | Maintenance of router bits and machine components | Wire replacement and tension adjustment | Blade replacement and machine upkeep |

| Setup and Programming | Requires setup and programming | Requires setup and programming | Requires setup and programming | Requires setup and programming |

| Tooling Maintenance | Low maintenance | Low to moderate maintenance | Minimal maintenance | Low maintenance |

| Cost | Higher initial cost | Moderate initial cost | Moderate initial cost | Lower initial cost |

| Waste Material | Minimal waste | Moderate waste | Minimal waste | Moderate waste |

Polystyrene is a synthetic polymer made from styrene monomer, which is derived from petroleum species. Styrene is derived from petroleum and is a clear, colorless liquid at room temperature that undergoes a polymerization process to form polystyrene. Polystyrene is a thermoplastic substance, which means it can be melted and molded into various shapes when heated and solidified when cooled. The chemical structure of polystyrene consists of long chains of styrene molecules, each containing a benzene ring and a pendant ethyl group.

The polymerization of styrene usually involves the use of heat and an initiator (a compound that initiates the polymerization reaction). During this process, styrene molecules join together to form long chains, forming a polymer called polystyrene. Depending on the specific manufacturing process, polystyrene can be produced in various forms, including solid plastic pellets, foam, or rigid sheets.

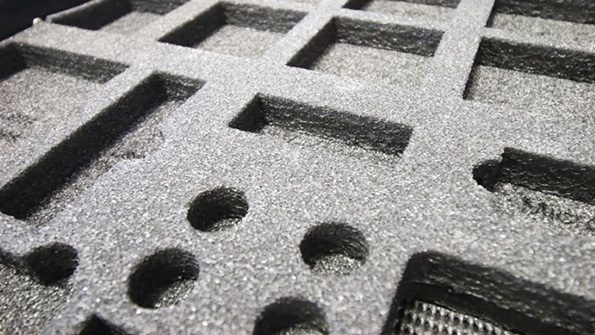

Polystyrene is widely used in various applications due to its lightweight, rigidity, and insulating properties. It is commonly used in the production of packaging materials, disposable tableware such as foam cups and foam trays, insulation, and foam products such as expanded polystyrene (EPS) for packaging and construction.

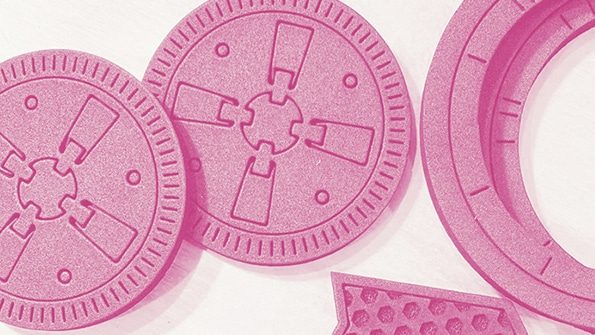

Yes, lasers can cut polystyrene. Polystyrene is a thermoplastic material, and laser cutting is an effective method of cutting thermoplastic materials such as polystyrene. Laser cutting works by using a highly focused laser beam to melt, burn, or vaporize material along a predetermined path, leaving clean, precise cuts.

When cutting polystyrene with a laser, proper laser settings (including laser power, cutting speed, etc.) should be used to obtain the desired cutting results. Polystyrene is a thermoplastic, which means it melts when exposed to heat. The laser’s focused beam provides the heat needed to cut through the material without excessive melting or charring of the cut edge.

Before attempting to laser cut polystyrene, it is advisable to consult with a professional or the laser cutting machine manufacturer to ensure proper settings and safety precautions are used for your particular application. Also, the thickness of the polystyrene sheet may affect the cutting parameters, so the laser settings must be adjusted accordingly for different thicknesses of polystyrene.

Laser cutting polystyrene can be performed safely, but due to the potential health and safety risks of the process, proper precautions and considerations need to be taken. Polystyrene is a thermoplastic material that can emit hazardous fumes and pose a fire risk when exposed to high temperatures during laser cutting. Here are some safety guidelines to follow when laser cutting polystyrene:

Laser-cutting polystyrene is safe if proper safety precautions are taken. However, safety requirements for laser cutting polystyrene can vary depending on the type of laser cutting machine, the specific polystyrene material, and local regulations. Be sure to consult the manufacturer’s guidelines and follow any applicable safety regulations in your area. If you are unsure about the safety of laser cutting polystyrene, consider seeking guidance from an expert or professional with experience in laser cutting and materials processing.

Laser cutting is an efficient and precise method of cutting polystyrene and can be used to create a variety of shapes and designs, but it has some drawbacks and limitations to be aware of:

Despite these disadvantages, it remains a valuable method of processing polystyrene when used in appropriate applications and with proper safety precautions. Knowing these limitations and addressing them can help you make an informed decision when choosing a cutting method for a particular project.

The type of polystyrene best suited for laser cutting is usually extruded polystyrene foam, often called XPS foam or foam board. This type of polystyrene is often used for laser cutting because it has special properties suitable for the laser cutting process.

While XPS foam is generally the first choice for laser-cutting polystyrene, be sure to consult the manufacturer’s guidelines for your particular laser-cutting machine, as different machines may have different requirements and settings for optimal cutting results. Also, always follow proper safety precautions when laser cutting polystyrene or any other material, including adequate ventilation and fire safety.

The thickness of the polystyrene can significantly affect the laser-cutting power requirements and the overall laser-cutting process. The following is the effect of thickness on laser cutting power:

The thickness of the polystyrene affects laser cutting power primarily because thicker materials require more energy to cut. Achieving the desired cut quality while avoiding excessive melting or charring typically requires a balance of laser power, cutting speed, and multiple cuts, depending on the thickness of the material. It is recommended to review the manufacturer’s guidelines and make test cuts to determine the best laser settings for a particular thickness of polystyrene sheet.

Laser-cut polystyrene can be prevented from deforming or melting through several mechanisms:

Precisely controlled heat application, optimized cutting parameters, rapid movements, ventilation, cooling systems, and the inherent properties of polystyrene as a laser-cut material all combine to help prevent deformation or melting during the cutting process.

Ensuring accuracy in laser cutting polystyrene involves several key steps and considerations:

By following these steps and implementing best practices, manufacturers can achieve reliable and accurate laser cutting of polystyrene materials for a variety of applications.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Polystyrene Laser Cutting Machine

Mary –

Exceptional cutting accuracy from laser machine. It’s a precise tool that ensures our products meet the highest standards.

Valentina –

Streamlined operations with our laser cutting machine. Its efficiency and precision have optimized our workflow, saving time and resources.

Rin –

Our laser cutting machine is a game-changer. It’s versatile, efficient, and consistently delivers high-quality results, exceeding our expectations.

Samuel –

Impressed by the performance and reliability of laser cutter. It’s a valuable asset that enhances our production capabilities.