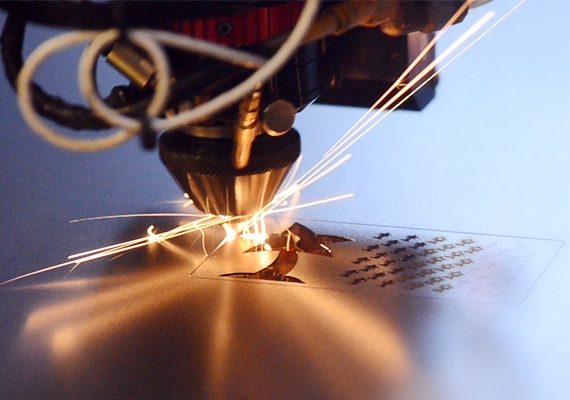

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

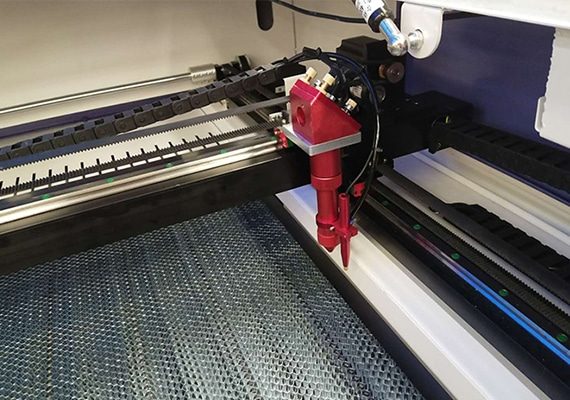

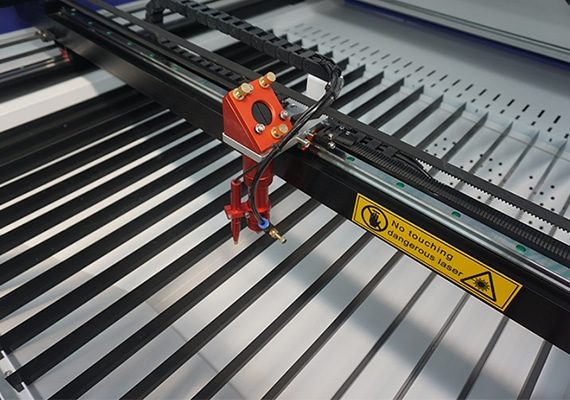

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

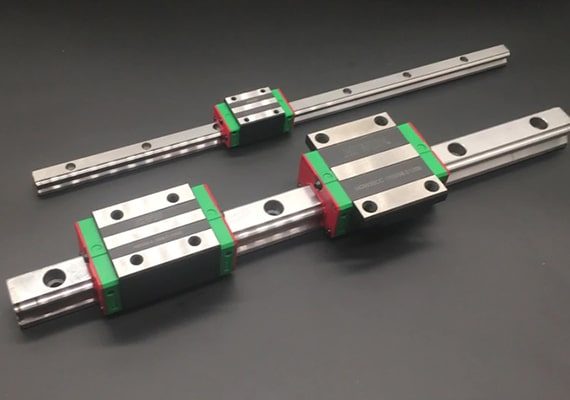

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

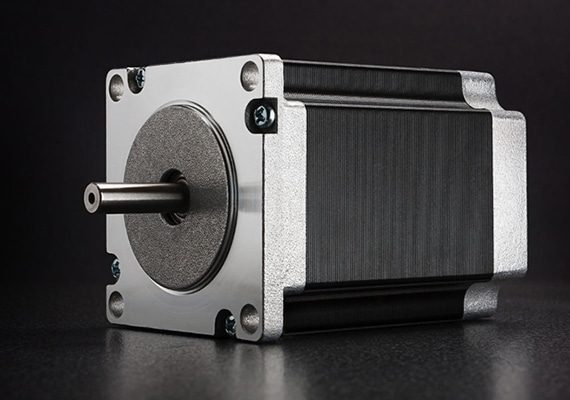

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 2mm | 3mm | 4mm |

|---|---|---|---|---|

| 25W | Max Cutting Speed | 15mm/s | 12mm/s | / |

| Optimal Cutting Speed | 13mm/s | 10mm/s | / | |

| 40W | Max Cutting Speed | 35mm/s | 30mm/s | 25mm/s |

| Optimal Cutting Speed | 32mm/s | 27mm/s | 20mm/s | |

| 60W | Max Cutting Speed | 50mm/s | 40mm/s | 35mm/s |

| Optimal Cutting Speed | 45mm/s | 38mm/s | 3mm/s | |

| 80W | Max Cutting Speed | 60mm/s | 50mm/s | 45mm/s |

| Optimal Cutting Speed | 58mm/s | 48mm/s | 40mm/s | |

| 100W | Max Cutting Speed | 70mm/s | 60mm/s | 55mm/s |

| Optimal Cutting Speed | 68mm/s | 58mm/s | 50mm/s | |

| 130W | Max Cutting Speed | 80mm/s | 70mm/s | 65mm/s |

| Optimal Cutting Speed | 78mm/s | 68mm/s | 63mm/s | |

| 150W | Max Cutting Speed | 90mm/s | 80mm/s | 75mm/s |

| Optimal Cutting Speed | 88mm/s | 78mm/s | 73mm/s | |

| 180W | Max Cutting Speed | 100mm/s | 90mm/s | 85mm/s |

| Optimal Cutting Speed | 98mm/s | 88mm/s | 80mm/s | |

| 200W | Max Cutting Speed | 120mm/s | 110mm/s | 100mm/s |

| Optimal Cutting Speed | 118mm/s | 108mm/s | 98mm/s |

| Cutting Process | Laser Cutting | CNC Routing | Saw Cutting | Ultrasonic Cutting |

|---|---|---|---|---|

| Precision | High precision | High precision | Moderate precision | Moderate to High precision |

| Versatility | Can handle various materials | Can handle various materials | Designed specifically for PVC | Can handle various materials |

| Intricate Cuts | Yes | Yes | Limited | Limited |

| Automation | Yes (Computer-controlled) | Yes (Computer-controlled) | Manual operation | Manual operation |

| Cutting Thickness | Suitable for various thicknesses | Suitable for various thicknesses | Limited to thin PVC sheets | Suitable for various thicknesses |

| Non-Contact Cutting | No | Yes | No | No |

| Portability | Depends on size | Depends on size | Highly portable | Portable |

| Cutting Speed | Moderate to Fast | Fast | Moderate | Moderate to Fast |

| Skill Requirements | Requires technical expertise | Requires technical expertise | Easy to use | Requires technical expertise |

| Cost | Expensive | Expensive | Affordable | Affordable |

Yes, laser cutting machines can be used to cut PVC (polyvinyl chloride) material. CO2 laser generators are very suitable for cutting PVC because they can effectively absorb the infrared light emitted by CO2 laser generators. The energy of the laser beam vaporizes or melts the PVC material at the point of contact, allowing precise cuts.

However, when laser cutting PVC, toxic fumes and particles are produced, which may contain chlorine gas. Proper ventilation and scheduling systems help ensure that fumes are removed and a safe working environment is maintained for the operator.

When proper safety precautions are taken and the proper settings are used, laser cutting machines can effectively cut PVC materials, delivering precise, clean results for a variety of applications. Always refer to your machine’s owner’s manual and safety guidelines provided by the manufacturer when working with specific materials like PVC.

Yes, cutting PVC (polyvinyl chloride) with a laser can cause a fire. PVC is a plastic that emits toxic fumes and can catch fire when exposed to high temperatures. When using a laser to cut PVC, the intense heat generated by the laser can cause the material to melt, releasing harmful chemicals and possibly igniting.

When PVC is burned, it releases chlorine gas and other toxic by-products, which are harmful to the environment and human health. Laser-cutting PVC releases corrosive chlorine gas that can cause respiratory irritation or other health problems if inhaled. Additionally, molten PVC can stick to laser-cutting equipment or surrounding surfaces, increasing the risk of fire.

To mitigate these risks, proper ventilation and safety measures should be taken when laser cutting PVC. Laser cutting machines are operated in a well-ventilated area with a proper exhaust system to ensure proper capture and removal of fumes and gases. Personal protective equipment (PPE), such as respirators, should also be used to minimize exposure to potentially harmful emissions.

If you are considering laser-cutting PVC, be sure to research and follow all safety guidelines provided by the laser-cutting machine manufacturer, as well as any relevant safety regulations, to minimize the fire and health risks associated with the process.

Yes, laser cutting PVC (polyvinyl chloride) releases harmful fumes and fumes. PVC is composed of chlorine and other chemicals, and when heated or vaporized during laser cutting, it emits chlorine-containing compounds and other toxic substances into the air. These emissions may include hydrogen chloride gas (HCl) and other volatile organic compounds (VOCs), which may be a health hazard if inhaled.

The release of these gases is of particular concern in poorly ventilated environments as they can build up and pose a health risk. Inhaling chlorine and hydrogen chloride fumes can cause respiratory irritation, coughing, and other health problems. Beyond the immediate health effects, there are more serious consequences of long-term exposure to these gases. Additionally, these emissions can corrode equipment and machinery, potentially causing damage over time.

To reduce the risks associated with using lasers to cut PVC, it is important to implement proper safety measures. Here are some precautions:

While laser cutting PVC releases toxic fumes, implementing proper ventilation, filtration, and safety measures can help minimize the release of harmful gases and particles. Additionally, consulting with manufacturers of PVC materials and laser-cutting machines can provide valuable insight into best practices for minimizing the risks associated with cutting PVC.

Laser cutting PVC (polyvinyl chloride) presents some disadvantages and challenges due to the nature of the material and the process involved. Some of the major disadvantages of laser cutting PVC include:

Given these drawbacks and challenges, it is imperative to thoroughly evaluate the risks and benefits before deciding to laser-cut PVC. If PVC cutting is required, strict adherence to safety guidelines, proper ventilation, and proper laser setup can help minimize risk and keep the operator and surrounding environment safe.

Cutting PVC (polyvinyl chloride) with a laser does present challenges due to the nature of the material and the nature of the laser itself. Here are some of the reasons why it is difficult for lasers to effectively cut PVC materials:

To overcome these challenges and achieve better results when cutting PVC, it may be necessary to adjust laser parameters such as power, speed, and focus, and to consider specialized equipment or techniques that help manage heat and fume emissions. Additionally, it is critical to employ proper ventilation and safety measures when working with PVC or any other material that emits potentially dangerous fumes during the laser cutting process.

To successfully cut PVC (polyvinyl chloride) with a laser, several factors and steps need to be considered to achieve a clean, precise, and safe cut. Here is a detailed overview of what needs to be done:

By carefully considering these factors and following the proper steps, you can ensure successful laser cutting of PVC while remaining safe and achieving the desired cut quality. Remember that special attention to ventilation and fume extraction is required when cutting PVC as harmful fumes may be released.

When laser cutting PVC, several safety precautions must be taken due to the potentially hazardous nature of the process. Here are some basic security measures:

By following these safety precautions, you can minimize the risks associated with laser-cutting PVC and create a safer working environment for your operators. Always put safety first and ensure all personnel are aware of potential hazards and how to mitigate them.

Yes, there are some environmental considerations associated with laser cutting PVC material due to the nature of PVC and the process itself:

Addressing these environmental issues requires a combination of technological solutions, such as pollution control systems and waste management practices, as well as organizational initiatives that promote sustainable practices and responsible resource use in laser-cutting operations.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for PVC Laser Cutting Machine

Ismail –

Impressed by the durability and performance of our CO2 laser cutter. It’s a reliable solution that ensures consistent, high-quality cuts.

Obinna –

Dependable performance from our laser machine. Its speed and accuracy make it a valuable asset for meeting our production demands.

João –

Our laser cutting machine has exceeded our expectations. It’s efficient, and versatile, and has become an integral part of our manufacturing process.

Esther –

Remarkable cutting quality from our laser cutter. It’s a reliable workhorse that consistently delivers flawless results, enhancing our productivity.