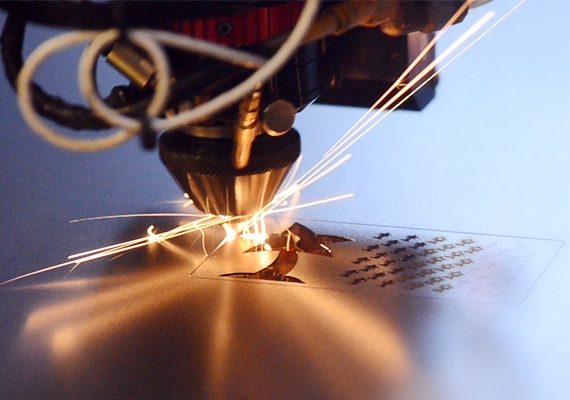

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

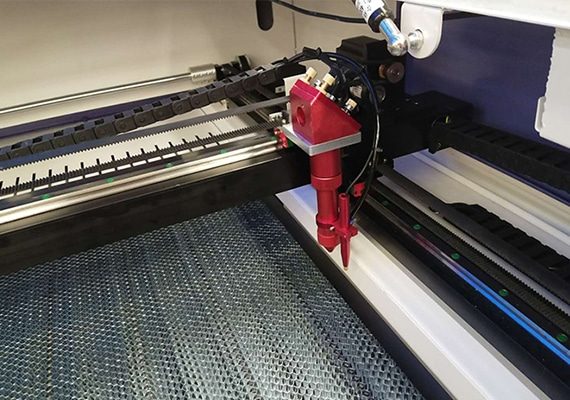

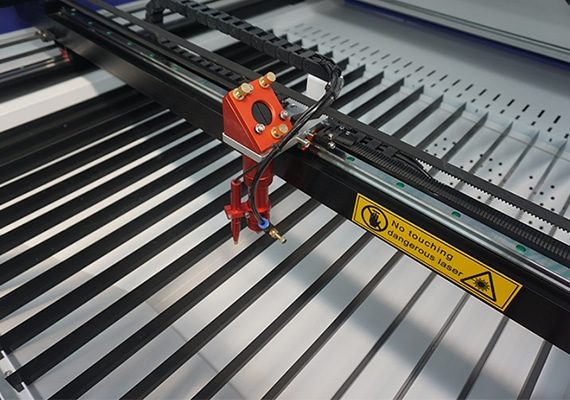

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

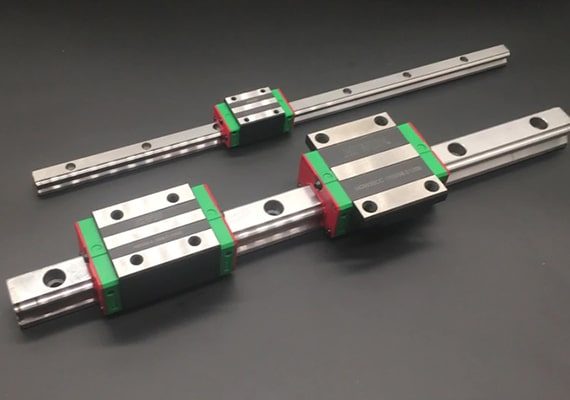

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

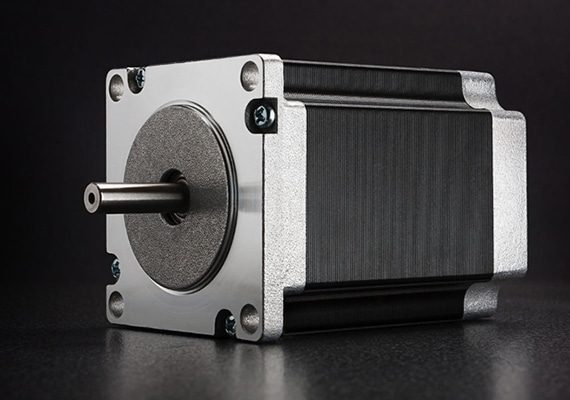

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000mm/min | ||||||

| Engraving Speed | 0-40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water Cooling | ||||||

| Laser Power | Cutting Speed | 0.5mm | 1mm | 2mm | 3mm | 5mm | 6mm |

|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 0.8mm/s | 0.7mm/s |

| Optimal Cutting Speed | 3mm/s | 2mm/s | 1.5mm/s | 1mm/s | 0.5mm/s | 0.4mm/s | |

| 40W | Max Cutting Speed | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1mm/s | 0.9mm/s |

| Optimal Cutting Speed | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 0.8mm/s | 0.6mm/s | |

| 60W | Max Cutting Speed | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1.8mm/s | 1.5mm/s |

| Optimal Cutting Speed | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 1mm/s | |

| 80W | Max Cutting Speed | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 2mm/s |

| Optimal Cutting Speed | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 1.5mm/s | 1.2mm/s | |

| 100W | Max Cutting Speed | 20mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2.5mm/s |

| Optimal Cutting Speed | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1.8mm/s | |

| 130W | Max Cutting Speed | 26mm/s | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 3mm/s |

| Optimal Cutting Speed | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 2mm/s | |

| 150W | Max Cutting Speed | 30mm/s | 18mm/s | 12mm/s | 8mm/s | 5mm/s | 4mm/s |

| Optimal Cutting Speed | 18mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2.8mm/s | |

| 180W | Max Cutting Speed | 36mm/s | 22mm/s | 14mm/s | 10mm/s | 6mm/s | 5mm/s |

| Optimal Cutting Speed | 22mm/s | 14mm/s | 10mm/s | 6mm/s | 4mm/s | 3mm/s | |

| 200W | Max Cutting Speed | 40mm/s | 24mm/s | 16mm/s | 12mm/s | 7.5mm/s | 6mm/s |

| Optimal Cutting Speed | 24mm/s | 16mm/s | 12mm/s | 8mm/s | 5mm/s | 4mm/s |

| Features | Laser Cutting | Router Cutting | Knife Cutting | Rotary Cutting |

|---|---|---|---|---|

| Precision | High precision | High precision | Moderate precision | Moderate precision |

| Cutting Speed | Fast | Variable, can be fast | Moderate | Fast |

| Material Versatility | Versatile, various materials | Versatile, various materials | Limited to veneer | Limited to veneer |

| Material Waste | Minimal | Minimal | Moderate | Moderate |

| Clean Edges | Clean, minimal | Clean | Clean | Variable |

| Intricate Cuts | Yes, intricate | Yes, intricate | Limited intricacy | Limited intricacy |

| Waste Generation | Minimal material waste | Minimal material waste | Moderate material waste | Moderate material waste |

| Charring/Burn Marks | Minimal to moderate | Minimal to none | Minimal to moderate | None |

| Heat Generation | Moderate | Variable | Minimal to moderate | Moderate |

| Maintenance | Moderate | Moderate | Low to moderate | Moderate |

| Material Thickness | Various thicknesses | Various thicknesses | Limited | Various thicknesses |

| Setup Time | Quick setup | Setup may take time | Quick setup | Setup may take time |

| Production Volume | Suitable for small to large volumes | Suitable for small to large volumes | Suitable for small volumes | Suitable for large volumes |

| Versatility | Versatile, various materials | Versatile, suitable for intricate designs | Limited to simpler shapes | Versatile, suitable for various veneer types |

The veneer is a thin layer of material (usually wood) that is usually applied over the surface of another material, often to improve its appearance, provide protection, or achieve a specific design or finish while reducing costs. Veneer allows manufacturers and craftsmen to achieve the look of high-quality wood without having to use solid wood throughout the process, which is expensive and less environmentally sustainable.

Wood veneer is typically produced by slicing or peeling thin sheets from logs, which can vary in thickness, usually between 0.6 and 6 millimeters (about 1/42 to 1/4 inch). The veneer is available from a variety of wood species, each with its unique grain pattern and color, allowing for customization and decorative effects.

The veneer is commonly used in furniture manufacturing, cabinetry, interior design, architectural applications, and decorative woodworking. It strikes a balance between the beauty of natural wood and the practicality of engineered materials, offering a wide range of design possibilities.

Yes, the veneer can be cut with a laser. Laser cutting is an effective method for cutting thin materials like veneer due to its precision and versatility. Veneer, typically made from thin sheets of wood or other materials, can be accurately cut into intricate shapes and designs using a laser cutting machine. The laser beam heats and vaporizes the material along the cutting path, resulting in clean and precise cuts with minimal kerf width.

When laser cutting veneer, it’s important to consider factors such as material composition, thickness, and quality. Adjusting the laser cutting parameters, including power, speed, and frequency, ensures optimal cutting results while minimizing the risk of burning or charring the material. Proper ventilation and safety measures are also essential to remove smoke and fumes generated during cutting, as the veneer is flammable. Overall, laser cutting offers an efficient and precise solution for cutting veneer for various applications such as crafts, signage, and decorative elements.

For cutting veneer, CO2 is the most suitable choice. The operating wavelength of the CO2 laser generator (approximately 10.6 microns) is easily absorbed by wood fibers, making it ideal for cutting organic materials such as wood. This absorption allows for efficient cutting, minimal carbonization, and excellent edge quality. Here are some reasons why CO2 laser generators are often considered the best choice for cutting veneer:

While CO2 laser generators are great for cutting veneer, make sure the CO2 laser cutting machine you choose has the right power level and settings for your specific veneer-cutting needs. When selecting the appropriate CO2 laser generator and machine, factors such as veneer thickness required cutting speed, and the complexity of the design to be cut should be considered. Additionally, proper ventilation and safety measures should be taken when operating CO2 laser-cutting equipment.

While laser cutting is a highly accurate and efficient method of cutting veneer, it does have some drawbacks and limitations that you should be aware of:

Despite these shortcomings, laser cutting remains an efficient and versatile method of cutting veneer, providing precision and customization that are often difficult to achieve with other cutting technologies. Careful selection of laser settings, material preparation, and operator training can help mitigate some of the disadvantages associated with laser cutting veneer.

Laser-cutting veneer is not inherently harmful to the environment, but there are environmental considerations and potential impacts associated with the process. Whether laser cutting veneer is harmful to the environment depends on a variety of factors and how the process is managed. Here are some environmental considerations:

Laser-cutting veneers can be environmentally friendly when considering energy efficiency, emissions control, material efficiency, and responsible sourcing and waste disposal practices. To minimize environmental impact, it is necessary to:

Laser-cutting veneers have an impact on the environment, mainly related to energy consumption, emissions, and resource utilization. To mitigate these impacts, responsible practices are needed, investing in efficient equipment and considering the environmental aspects of the materials used. Sustainable sourcing and disposal practices also help reduce the environmental footprint of laser-cut veneer.

Laser-cutting veneer is safe if proper precautions and safety measures are taken. But it also poses potential risks, and following safety guidelines can help minimize those risks. Here are some key safety considerations when cutting veneer with a laser:

By following these safety measures and guidelines, the risks associated with laser cutting veneer can be minimized and the process can be performed safely. Workplace safety must be prioritized to protect operators and equipment. If you are unfamiliar with laser safety practices, it is recommended that you seek training or consult with a laser technology expert to ensure safe and responsible operation.

When laser cutting veneer, safety must be prioritized to prevent potential hazards. Here are some key security measures to consider:

By implementing these safety measures and guidelines, you can minimize the risks associated with laser-cutting veneers and create a safer work environment for yourself and others.

Several factors affect the speed and accuracy of laser-cutting veneer:

By considering these factors and optimizing cutting parameters, you can maximize the speed and accuracy of laser-cutting veneers while maintaining high-quality results.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Veneer Laser Cutting Machine

Ahmed –

Consistently impressed by our laser machine’s capabilities. It’s a versatile tool that adapts to various materials and thicknesses effortlessly.

Mio –

Exceptional value for our investment. Our CO2 laser cutting machine delivers superior results, proving to be a worthwhile addition to our workshop.

Ana –

Seamless integration into our workflow. Our laser machine is intuitive, and efficient, and empowers us to tackle complex projects with ease.

Amina –

Reliable and efficient performance from our laser cutter. It’s a reliable asset that ensures consistent quality in our manufacturing processes.