Running a Laser Cutting Business: Regulations And Certifications

Laser cutting is a versatile and precise technology that has found applications in a variety of industries, from manufacturing to art. As the demand for precision cutting and engraving services continues to grow, many entrepreneurs are considering starting their own laser-cutting business. It is recommended before venturing into this area to understand the specific regulations and certifications that may be required to operate this type of business safely and legally. In this comprehensive article, we’ll look closer at the world of laser-cutting businesses and explore the regulatory and certification requirements entrepreneurs must consider. We’ll cover topics from business licensing and environmental regulations to safety standards and quality control certification, providing a detailed introduction to each aspect. After reading this article, you will have a clear understanding of the requirements and responsibilities associated with running a successful and compliant laser-cutting business.

Table of Contents

What is a laser cutting business?

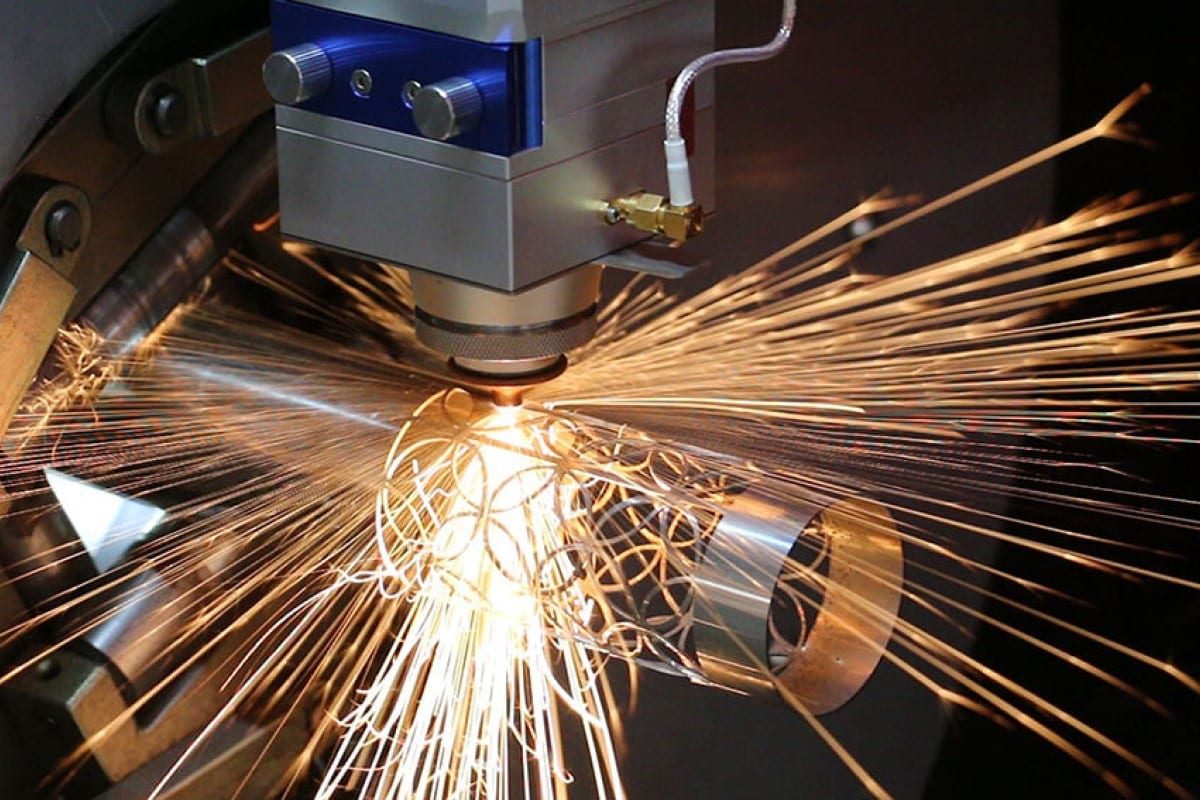

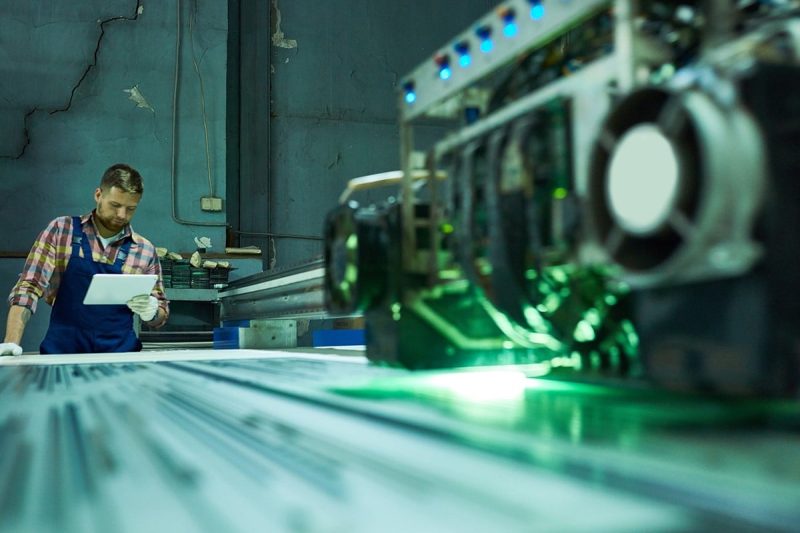

Laser cutting business refers to companies that utilize laser technology to cut, engrave, or mark various materials. These materials range from metals and plastics to wood and ceramics. Laser cutters use a highly focused laser beam to precisely cut and engrave materials, making them an important tool in many industries, including manufacturing, design, and even art.

Types of laser cutting machines

Many laser-cutting machines are classified primarily based on the type of laser generator they use. The two most common types are:

- CO2 Laser Cutting Machine: These machines use carbon dioxide gas to generate a laser beam. It’s ideal for cutting non-metallic materials, including wood, acrylics, and fabrics.

- Fiber Laser Cutting Machine: Fiber laser generators use solid media and are very efficient at cutting metals, especially stainless steel and aluminum. The choice of laser cutting machine depends on the materials you plan to use and the specific requirements of your business.

Regulatory landscape

Running a laser cutting business requires compliance with various regulations at the local, state, and federal levels. The main objectives of these regulations are to ensure the safety of operators and the public, maintain environmental standards, and adhere to quality control. Let’s break down the key areas of regulation that business owners must address.

Business licenses and permits

Before we get into the details of laser cutting, let’s first understand the basic requirements for starting any business and obtaining the necessary business licenses and permits. Like any other commercial enterprise, laser-cutting businesses need to be registered and licensed in their respective jurisdictions.

Business license

The basic requirement for starting a laser cutting business is a business license. This document authorizes you to legally operate a laser-cutting business within your city or county. The specific processes and fees associated with obtaining a business license vary depending on your location, and it is recommended to check with your local government or Small Business Administration (SBA) for guidance. In some cases, you may need a general business license, while in other cases you may need a specialized license to manufacture or operate a high-power laser generator.

Zoning and land use regulations

The location of your laser cutting business may be subject to local zoning and land use regulations. Zoning codes determine where certain types of businesses can operate. Make sure your business location complies with these regulations to avoid any legal issues or potential fines.

Building regulations and construction permits

If you are constructing a new building or renovating an existing building for your laser-cutting business, you will need to comply with local building codes and obtain the necessary construction permits.

Taxation and reporting

Running a business also means complying with tax regulations. If you have employees, you may need to obtain an Employer Identification Number (EIN) from the IRS, and you must report and pay various taxes, including income tax, payroll tax, and sales tax. Keeping meticulous financial records and working with an accountant or tax professional can help ensure you meet all tax obligations.

Environmental regulations and emission controls

The laser cutting process produces emissions, especially when cutting or engraving certain materials. Emissions may include particulate matter, smoke, and volatile organic compounds (VOCs). Therefore, it is necessary to understand and comply with environmental regulations to minimize the impact of your business on the environment.

Air quality and emissions

Laser cutting releases emissions into the atmosphere, including particulate matter and gases. Depending on the material you are cutting and the equipment you are using, you may need to comply with local air quality regulations. This may involve installing exhaust systems, filters, or emission control technology to minimize environmental impact.

Waste disposal

Laser cutting produces waste materials such as scrap metal and used laser optics. Proper disposal of these materials helps avoid environmental pollution. Make sure to comply with local waste disposal regulations and consider recycling or reusing materials where possible. Please be aware of any specific requirements related to the disposal of materials used for laser cutting, as some materials may contain hazardous substances.

Chemical safety

Depending on the material being cut, there may be regulations related to the storage and handling of hazardous chemicals. Become familiar with the Safety Data Sheet (SDS) for any chemicals used in the laser cutting process and ensure compliance with applicable regulations.

Occupational safety and OSHA compliance

Safety is crucial in any industry, and the laser-cutting business is no exception. The U.S. Occupational Safety and Health Administration (OSHA) sets guidelines and regulations to ensure the safety and well-being of workers. Complying with OSHA standards helps maintain a safe work environment.

Workplace safety

Complying with OSHA standards means creating a safe workplace for your employees. This includes ensuring that laser cutting equipment is properly maintained, that workspaces are organized and hazard-free and that personal protective equipment (PPE) is available and used as required. You must also have appropriate safety procedures and emergency plans in place.

Employee training

Properly trained employees are vital to workplace safety. OSHA regulations generally require training programs related to equipment operation, safety protocols, and emergency response. Regular safety training sessions and maintaining training records are common OSHA requirements.

Keep records

Depending on the material being cut, there may be regulations related to the storage and handling of hazardous chemicals. Become familiar with the Safety Data Sheet (SDS) for any chemicals used in the laser cutting process and ensure compliance with applicable regulations.

Fire code and safety

The high temperatures and concentrated energy involved in laser cutting make it a fire hazard, making fire safety a top priority for laser cutting companies. Complying with fire codes and safety standards helps protect your business and the people who work on your premises.

Fire extinguishing system

Depending on your location and the size and nature of your operation, you may need a fire suppression system such as sprinklers or fire alarms. Complying with fire suppression regulations can help protect your business and its assets. Additionally, these systems must be maintained and tested regularly to ensure they are functioning properly.

Fire prevention measures

Implementing fire prevention measures in the workplace can reduce the risk of fire. This may include reducing the risk of fire in the workplace by keeping flammable materials away from laser-cutting equipment, providing clear evacuation routes, and ensuring electrical systems meet safety standards.

Contingency plan

Develop and communicate emergency response plans to employees. The plan should include procedures for evacuating the premises in the event of a fire and guidelines for contacting emergency services. Regular drills and training on these procedures help ensure a quick and effective response in the event of a fire.

Laser safety standard

Laser safety is crucial in the laser cutting business. The power and intensity of laser beams pose potential risks to both operators and bystanders. To mitigate these risks, several organizations, including the American National Standards Institute (ANSI) and the International Electrotechnical Commission (IEC), have developed laser safety standards. The specific details of these standards depend on the class and power of the laser system.

Laser classification

Laser systems used for cutting are divided into different categories based on their power and potential to cause damage to the human eye and skin. These categories range from Class 1 (no hazard) to Class 4 (highly hazardous), and different classes of lasers require different specific safety measures and protective equipment. It is critical to accurately classify and label laser equipment and provide the necessary safety measures for each category.

Laser safety officer (LSO)

In many laser-cutting operations, it is recommended to appoint a laser safety officer. The LSO is responsible for implementing and maintaining laser safety protocols, conducting safety assessments, and ensuring employees receive appropriate laser safety training. Depending on the type of laser used and its power level, you may need to have a designated LSO.

Protective equipment

High-power lasers can cause eye damage, so operators are required to wear goggles and glasses to protect workers’ eyes from laser radiation. The type of protective eyewear required depends on the wavelength and power of the laser. Make sure your employees have access to and use appropriate protective equipment based on the equipment being used.

Laser interlocking function

Laser-cutting machines should be equipped with interlocking features to prevent unauthorized access during operation. This feature is designed to shut down the laser generator if the safety measures are compromised.

Warning labels and placards

Proper labels and signage are crucial in the world of laser cutting. Laser warning labels must be affixed to equipment and workstations to alert individuals of potential laser hazards. In addition, clear signage should mark laser control areas and specify safety procedures and the use of protective eyewear.

Machine safety certification

The laser cutting machine itself must meet safety and performance standards in order to be safely permitted. Certification and regular inspections help ensure your equipment meets safety requirements. In addition, different countries may have different certification requirements for the safe operation of laser-cutting machines.

Device compliance

Laser-cutting machines should meet safety and performance standards of regulatory agencies and industry organizations. Before purchasing or operating laser systems, make sure they meet these standards. Some important equipment safety standards include:

- ANSI (American National Standards Institute)

- IEC (International Electrotechnical Commission)

- NFPA (National Fire Protection Association)

Inspection and maintenance

Regular inspection and maintenance of your laser cutting equipment helps ensure its safe operation. Regular inspections can help identify potential problems and ensure equipment remains in good working order. Many standards recommend that devices undergo security assessments at specific intervals.

Operator training

Properly trained equipment operators help maintain a safe work environment. Make sure your employees are trained to operate laser cutting equipment safely, including understanding emergency procedures, equipment shutdown, and identifying potential hazards.

Material regulations

The materials you use may also be subject to specific regulations, especially if they contain hazardous substances. For example, the use or disposal of materials such as lead-based paint, asbestos, or certain plastics may be restricted. Understanding and following these regulations helps ensure employee safety and the quality of their work.

Hazardous materials handling

If your laser cutting business uses materials that are classified as hazardous or hazardous, such as certain metals or plastics, then you must comply with safety regulations that govern their handling, storage, and disposal. Make sure you take appropriate safety measures to minimize the risks associated with these materials.

Material compatibility

Different materials react differently to laser cutting. It is necessary to understand the compatibility of the material with the laser equipment and any potential by-products or emissions produced when cutting a specific material. This knowledge can help you manage the potential risks associated with different materials.

Material data sheet

For safety and quality control purposes, it is recommended to retain a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for the materials you use. These documents provide information on the properties, hazards, and safe handling of materials. In the event of an emergency or safety issue, the MSDS or SDS sheet can serve as a valuable reference.

Quality control certification

Quality control is a critical aspect of any manufacturing or cutting operation. While it’s not a legal requirement like safety regulations, obtaining quality control certification can help demonstrate the quality and consistency of your work.

ISO 9001 (Quality management system

ISO 9001 is an internationally recognized quality management system standard. Obtaining ISO 9001 certification demonstrates your commitment to maintaining high-quality standards and continuous improvement of operations. This certification can enhance your reputation and open the door to new business opportunities.

Industry-specific quality standards

In addition to ISO 9001, specific industries may have their own quality standards and certifications. For example, the aerospace or medical device manufacturing industries often have strict quality control requirements. If you plan to do business in these markets, you need to meet these industry-specific standards: AS9100 (aerospace standard) and ISO 13485 (medical devices).

Customer expectations

Listening to and understanding your customers’ quality expectations is critical, meeting or exceeding these expectations can lead to repeat business and referrals. Continuously delivering quality work will help build a strong reputation in the industry.

Insurance

Insurance is an important component of risk management for any business. For a laser-cutting business, specific types of insurance can provide protection against a variety of liabilities and risks. The insurance coverage you need to purchase is relevant to the risks associated with your business.

General liability insurance

General liability insurance covers accidents, injuries, or property damage that may occur on your premises or as a result of your operations. This is an important safeguard to protect your business from potential lawsuits and liability.

Workers’ compensation insurance

If you have employees, workers’ compensation insurance is usually required by law. It provides financial support to employees who are injured or become ill due to a work-related incident. Complying with workers’ compensation requirements can help protect your employees and your business from legal trouble.

Property insurance

Property insurance covers your business assets, including equipment, inventory, and workspace, against damage or loss due to events such as fire, theft, or natural disasters. This coverage is vital in helping to protect your investment.

Industry associations and networks

Joining an industry association can be beneficial for your laser-cutting business. These organizations are constantly up to date on the latest industry developments, security guidance, and best practices.

Laser Institute of America (LIA)

Participation in industry associations and organizations can provide valuable resources, networking opportunities, and access to industry-specific information. The Laser Institute of America (LIA) is a renowned organization in the field of laser technology. Membership in such organizations can help you stay up to date on the latest industry trends, connect with other professionals, and gain access to educational resources.

Social opportunities

Networking within the laser cutting industry can help you stay up to date on the latest technology and best practices. Building relationships with suppliers, competitors, and potential customers can lead to valuable partnerships and business opportunities.

Industry-specific information

Trade associations often provide members with access to research, publications, and industry-specific information. Staying informed about the latest developments in laser cutting technology, materials, and safety standards can help you stay competitive in the market.

Local zoning and building codes

Before setting up a laser cutting business, you must ensure that your business location complies with local zoning and building codes. Zoning regulations define the types of businesses allowed in a specific area while building codes dictate construction and safety standards for facilities.

Zoning regulations

Make sure your zoning district allows your business activities. It is recommended to check with local zoning agencies to ensure that the location you choose is zoned for industrial or commercial use and that there are no restrictions that prevent you from starting a laser-cutting business.

Building regulations

When building or renovating your business premises, you must comply with local building codes. These codes cover aspects such as structural integrity, electrical systems, and fire safety. Failure to comply may result in safety hazards and legal issues.

Summarize

Starting and running a laser cutting business can be a rewarding career, but it comes with the need to navigate a complex web of regulations and certifications. The key to success is thorough research, diligent compliance with legal and safety requirements, and a commitment to quality and environmental responsibility. By obtaining the necessary licenses, adhering to environmental regulations, limiting safety considerations, adhering to laser safety standards, maintaining its safety certifications, and meeting materials regulations, your business can operate legally, safely, and responsibly. Additionally, obtaining quality control certification, obtaining appropriate insurance, and partnering with industry associations can help your business thrive in a competitive market.

It is important to stress that the regulations and certifications mentioned in this guide may vary from location to location and may change over time. Therefore, ongoing efforts are required to keep up with changing standards and requirements. Always consult with relevant authorities, industry experts, and legal professionals to ensure your laser-cutting business is fully compliant and successful. By following the guidelines and best practices outlined in this comprehensive guide, you can build a laser cutting business that is not only legal, but also prioritizes safety, quality, and environmental responsibility, ultimately contributing to the long-term success and growth of your business.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions