Safety Precautions When Using CO2 Laser Cutting Machine

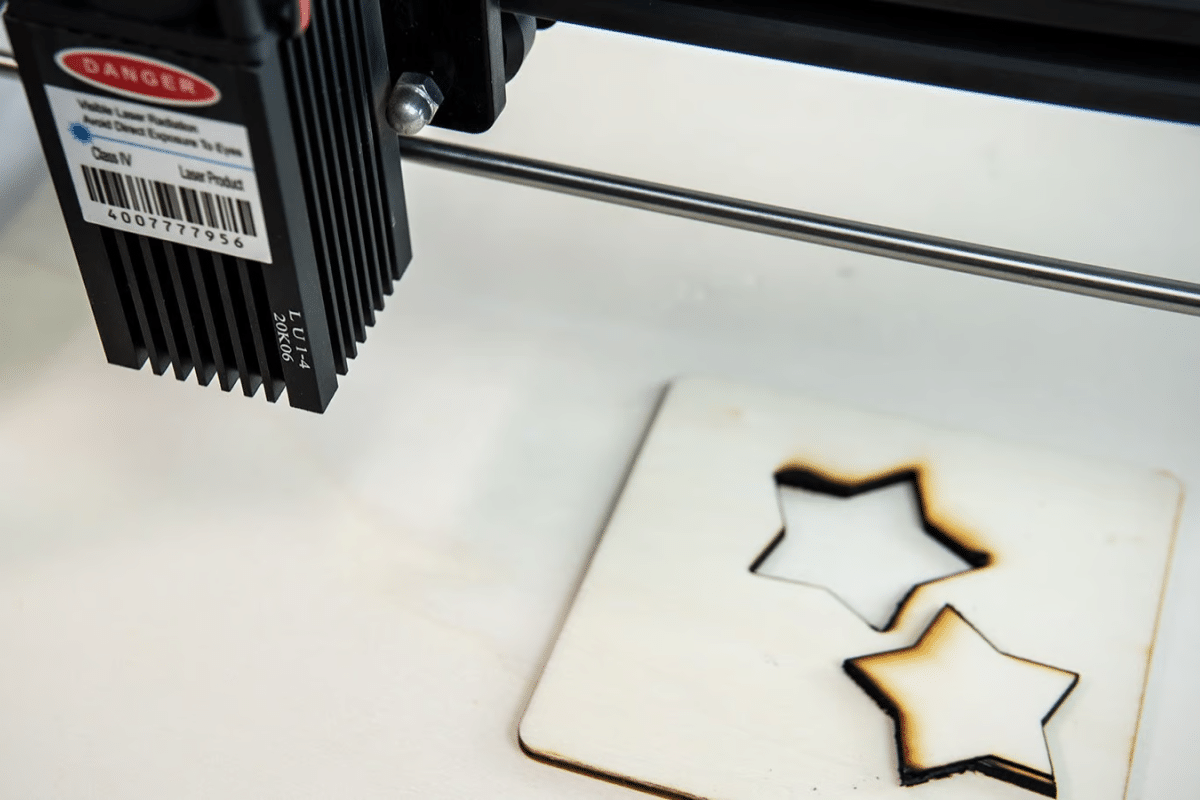

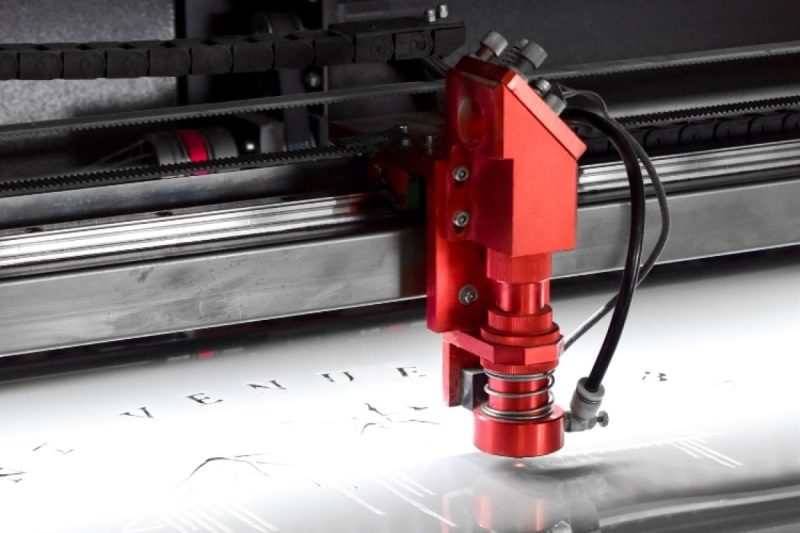

A CO2 laser cutting machine is a high-precision tool widely used in industry and manufacturing that utilizes a laser beam to cut a variety of materials, including metal, plastic, wood, and fabric. Despite its wide range of applications, the operation of CO2 laser cutting machines involves a series of potential dangers and safety hazards. Therefore, it is crucial to strictly adhere to safety precautions when using a CO2 laser-cutting machine. This article will discuss in detail the specific safety precautions when using a CO2 laser cutting machine to ensure the safety of the operator and the efficient operation of the equipment.

Table of Contents

Working principle of CO2 laser cutting machine

The CO2 laser cutting machine is a laser cutting system that utilizes a CO2 laser generator for precise cutting. How a series of sperm is guided to a cutting head where it is focused into a laser beam to cut the material. Here is a step-by-step explanation of how a CO2 laser-cutting machine works:

- Laser generator: The core of the CO2 laser cutting machine is the CO2 laser generator, which generates a high-energy laser beam. The active medium of the laser generator is CO2 gas, which excites the gas molecules by electric shock to produce laser photons. These photons are repeatedly reflected in the gainer, gradually increasing in intensity, forming a high-energy laser beam.

- Amplification of laser beam: Optical gainers usually consist of mirrors and optical lenses. Laser photons are reflected and amplified in the optical gainer to form a high-intensity laser beam.

- Regulation of laser beam: In laser cutting machines, the laser beam can be regulated through optical elements, which are used to guide the laser beam to the cutting area and ensure the quality of the laser beam. to change its intensity, focus, and shape.

- Cutting process: When the high-energy laser beam is focused on the working area, it generates high temperature and high energy, which will cause local melting and evaporation of the material being cut, allowing the CO2 laser cutting machine to achieve very fine cutting.

- Gas assist: During the cutting process, gas assist is usually used to purge the cutting area, which helps reduce the thermal impact and material deformation of the cutting area and improves cutting quality.

- CNC systems: CO2 laser cutting machines are usually equipped with CNC systems that allow operators to control the intensity, speed, focus position, and cutting path of the laser beam.

The versatility and accuracy of CO2 laser cutting make it a popular choice for many manufacturing and manufacturing applications. However, when using a CO2 laser cutting machine, safety guidelines and proper maintenance must be followed to ensure the safe and efficient operation of the equipment.

What are the hazards caused by improper use of CO2 laser cutting?

Improper use of CO2 laser cutting machines may cause a series of serious hazards, covering all aspects of the operator, equipment, environment, and materials. Here are some possible hazards:

Hazards to operators

- Eye Injury: Eyes exposed directly to the CO2 laser beam may suffer damage, including retinal burns or permanent vision loss.

- Skin Burns: Skin exposed to CO2 laser beams may suffer burns, especially with high-power lasers.

- Respiratory Problems: During the cutting process, some materials may produce harmful gases that may cause respiratory problems or other health problems if the operator inhales these gases.

Hazards of equipment

- Equipment Failure: Improper use may cause equipment failure, requiring expensive repairs or replacement parts.

- Damaged Lenses and Optics: If the laser beam is incorrectly aimed at the material or if the material is sprayed onto the lenses and optics, it can be damaged, reducing the performance of the device.

- Fire Risk: Improper use of laser cutters can cause fires because the high-energy laser beam can ignite flammable materials.

Environmental hazards

- Emissions: During the cutting process, some materials produce harmful gases and dust, which can negatively impact indoor air quality and the environment.

- Noise: Laser cutting machines may produce noise when operating, which may cause disturbance to the operating environment and nearby workers.

Material Hazards

- Material Burning: Incorrect laser parameter settings or focus position may cause material burning and affect cutting quality.

- Material Deformation: High-temperature laser beams can cause material deformation, especially in metal cutting.

- Material Contamination: Laser cutting may leave stains or residues on the material surface, affecting product appearance and quality.

Safety precautions when using CO2 laser cutting machine

To avoid these hazards, we need to operate the CO2 laser cutting machine correctly. To use and maintain the equipment within a safe range, the following precautions must be taken:

Safe operation procedures

- Check the Equipment: Before the operation, check the equipment status of the CO2 laser cutting machine to make sure everything is normal. Including inspection of laser generators, optical components, cooling systems, and control systems. If any fault or abnormality is found, stop operation immediately and notify maintenance personnel.

- Operating Environment Preparation: Make sure the operating area is well-ventilated to eliminate smoke and exhaust fumes generated during laser cutting. Install a fire extinguisher near the cutting area to respond to possible fire situations.

- Material Preparation: Choose a material that is suitable for laser cutting and make sure it is secured to the work platform to prevent movement or material jamming. Avoid using flammable materials such as PVC, etc.

- Equipment Preparation: Start the CO2 laser cutting machine and ensure that all systems are operating normally, including the cooling system, gas supply system, and CNC system. Adjust laser parameters such as power, speed, and focus position to suit the type and thickness of the material to be cut.

- Operating Procedures: Use the CNC to set cutting paths and patterns. Make sure the operator stands behind the equipment to avoid direct exposure to the laser beam.

- Avoid Placing Reflective Objects: Avoid placing reflective objects near the cutting area. Start the laser cutting machine and cut strictly according to the operating procedures.

Operator safety

- Training and Certification: Only trained and certified operators should use CO2 laser cutting machines. Training should include equipment operation, safety procedures, maintenance points, and emergency handling. Ensure that operators understand the basic principles and operating procedures of the laser cutting machine to reduce operational risks.

- Personal Protective Equipment: Operators should wear appropriate personal protective equipment, including protective eyewear, face shields, gloves, and clothing. This equipment can effectively reduce the damage to skin and eyes caused by laser beams and material splash.

- Prevent Laser Radiation: Laser radiation is harmful to the human body, so operators should avoid direct exposure to the laser beam at all times. While working, operators should stand behind the equipment and avoid standing in the path of the laser beam. Additionally, use shields or shielding devices to limit the spread of laser radiation.

- Safe Distance: Keep the operator and any bystanders away from the laser cutter’s work area. Specifying a safe distance reduces the risk of injury from the laser beam and material splash that may occur during the cutting process.

- Do Not Illuminate Reflective Objects: Reflective objects may reflect the laser beam to unintended locations, so it is prohibited to place or use reflective objects near the cutting area. This includes mirrors, metal surfaces, and glass.

Material Handling Safety

- Choose the Right Material: Before using a CO2 laser cutting machine, make sure the selected material is suitable for laser cutting. Different materials have different cutting characteristics, so laser parameters and cutting speed need to be adjusted to get the best results. Using unsuitable materials can result in poor cut quality and equipment failure.

- Safe Material Handling: Materials can produce harmful gases and dust during cutting, so appropriate measures must be taken to control these emissions. Typically, an exhaust system is used to discharge exhaust gases outdoors, and dust extraction equipment is used to collect dust.

- Avoid Volatile Materials: CO2 laser cutting machines generate high temperatures during the cutting process, so avoid using volatile materials to prevent the production of flammable gases and dangerous vapors. These materials include polyvinyl chloride (PVC), etc.

- Prevent Materials From Getting Stuck: Make sure the materials being cut are properly clamped to prevent them from moving or getting stuck during the cutting process. Unstable materials can cause cutting machine failure and unsafe conditions.

Equipment environment and security

- Regular Maintenance and Inspection: Before using the CO2 laser cutting machine, first make sure that the equipment is in good working order. Perform regular maintenance and inspections, including the laser generator’s cooling system, optical components, laser gas supply system, and control system. This helps reduce the risk of equipment failure and ensures operational safety.

- Suitable Operating Environment: Make sure the CO2 laser cutting machine is in a suitable operating environment. This includes a well-ventilated room to remove smoke and exhaust fumes from laser cutting. Additionally, operating areas should be kept tidy to reduce the risk of tripping and other accidental injuries.

- Fire Prevention Measures: Since the laser cutting machine generates high temperatures, make sure there are no flammable substances such as paper, paint, and solvents around it during operation. Install a fire extinguisher near the cutting machine and check its effectiveness regularly. Establish an emergency fire suppression plan near equipment to respond to possible fire situations.

- Safety Signs and Emergency Stop Buttons: Safety warning signs should be marked around the CO2 laser cutting machine to remind operators of dangers. In addition, the equipment should be equipped with an emergency stop button to quickly cut off the power supply in the event of a dangerous situation.

Emergency handling

- Emergency Stop Procedure: When using a CO2 laser cutting machine, the operator must clearly understand the emergency stop procedure. If any dangerous situation occurs, the operator should immediately press the emergency stop button, cut off the power supply, and take appropriate measures to deal with the problem.

- Burn and Injury Treatment: If an operator or bystander is injured, provide immediate medical assistance. For burns, rinse the injured area with cold water and seek medical attention promptly. For other injuries, appropriate first aid measures should also be taken, such as dressing the wound or performing CPR.

- Fire Handling: If a fire occurs, press the emergency stop button immediately and use a fire extinguisher to put it out. If the fire cannot be controlled, notify the fire department immediately and ensure that all personnel evacuate safely.

Other safety precautions

- Keep Unauthorized Personnel Away From the Equipment: Only trained and authorized personnel should approach the CO2 laser-cutting machine. Unauthorized persons must not touch the device or operate the control panel.

- Comply with All Regulations and Standards: When using CO2 laser cutting machines, operators must comply with all applicable regulations and standards, including national and local safety regulations. These regulations and standards are designed to ensure safe and environmentally friendly operations.

- Regular Training and Updates: Security training should not be just a one-off. Operators should receive regular training and updates to maintain their knowledge and skills to address new safety challenges and technological improvements.

Summarize

Using a CO2 laser cutting machine is a highly sophisticated job, but it also comes with a host of potential hazards and safety risks. To ensure the safety of operators and the efficient operation of equipment, it is crucial to strictly adhere to the above safety precautions. By adhering to these safety precautions, you can ensure the safe operation of your CO2 laser-cutting machine while improving work efficiency and quality.

If you are looking for a reliable CO2 laser cutting machine for your business, AccTek Laser is a one-stop solution for all your needs. Here you’ll find our range of CO2 laser cutting machines, accessories, software, and everything you need to get the best out of your laser cutting machine.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions