What Are the Common Problems of Laser Cleaning Machines?

As an advanced non-contact cleaning equipment, a laser cleaning machine removes pollutants from the surface of the substrate with high-energy laser beams. It has been widely used in industrial rust removal, coating removal, mold cleaning, and cultural relics protection. Compared with traditional cleaning methods, laser cleaning technology has gradually become the preferred cleaning method in many industries due to its advantages such as high efficiency, environmental protection, and low damage to the substrate.

However, เครื่องทำความสะอาดเลเซอร์ still encounter some common problems in actual operation, such as insufficient cleaning efficiency, thermal damage to substrates, high operating costs, safety risks, and limited material compatibility. These problems may affect the cleaning effect and the long-term use of the equipment, so it is very important to have a deep understanding of these problems and properly solve them.

สารบัญ

Laser Cleaning Technology Overview

Laser cleaning is a modern non-destructive cleaning technology that uses a high-energy laser beam to act on the surface of the material to quickly vaporize, decompose, or peel off pollutants, oxide layers, or other unwanted attachments without causing physical wear to the substrate. This technology has received widespread attention in the past few years and has gradually been applied to many fields such as industrial manufacturing, automobile maintenance, aerospace, shipbuilding, and cultural relics protection. It has become the preferred cleaning method in many industries due to its precise and environmentally friendly characteristics.

การทำความสะอาดด้วยเลเซอร์ทำงานอย่างไร

The core principle of laser cleaning is to use a high-intensity laser beam to focus on the cleaning surface, causing the contaminants to absorb the light energy and quickly expand, vaporize, or decompose, and remove them through physical force and heat energy. The specific process includes two main steps:

- Laser action process: The laser beam focuses on the surface of the pollutant with extremely high energy density, and the temperature of the pollutant surface rises sharply, causing the pollutant molecules to expand or vaporize. The substrate absorbs less laser energy and maintains a lower temperature, avoiding excessive thermal effects.

- Instant peeling: The heated pollutant is peeled off from the substrate due to rapid expansion, forming tiny particles, gas, or plasma. Generally, it is combined with a smoke separation device to prevent these vaporized products and particles from entering the air.

Advantages of Laser Cleaning Technology

Compared with traditional mechanical, chemical, and ultrasonic cleaning methods, laser cleaning has a series of significant advantages:

- Non-contact: Laser cleaning does not need to contact the material surface, avoiding friction and wear, so it is suitable for parts with high-precision requirements and heat-sensitive materials.

- Environmental protection: Laser cleaning does not require chemical solvents, the waste is a small number of particles and gases, and the pollutants produced have less negative impact on the environment.

- High precision and controllability: Laser can accurately control energy, wavelength and pulse duration, suitable for micron-level fine processing and cleaning, avoiding damage to the substrate surface.

- Wide range of material applicability: Laser cleaning can be applied to a variety of materials such as metals, ceramics, rubber, glass, etc., with a wide range of adaptability.

Typical Applications of Laser Cleaning

Laser cleaning has a wide range of applications, covering many fields:

- Industrial rust removal: Laser cleaning can effectively remove oxide layers, rust, etc. on metal surfaces, and is particularly suitable for rust removal of precision parts and large structures.

- Coating stripping: Used to remove paint, coatings, etc. on metal surfaces, commonly used in coating removal in the automotive manufacturing and aerospace fields.

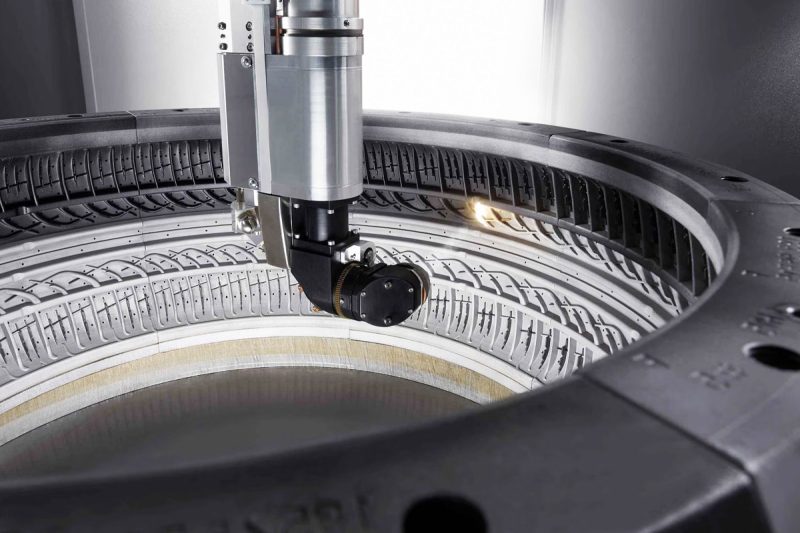

- Mold cleaning: Laser cleaning can accurately remove residues on the surface of plastic and rubber molds, reduce mold loss, and improve product quality.

- Cultural relic protection: Laser cleaning technology can be used to remove dirt and oxide layers on cultural relics, stone carvings, and other artworks, and repair and protect them without damaging the cultural relics.

Common Problems of Laser Cleaning Machines

As a new type of industrial cleaning method, laser cleaning is widely used in many fields. However, in actual use, there are still some common problems in terms of equipment cleaning effect, substrate protection, operating costs, safety and material compatibility. These problems not only affect the cleaning effect, but may also lead to increased equipment operating costs or safety hazards. Therefore, to improve cleaning efficiency and equipment life, it is very necessary to understand the causes of these problems and take appropriate countermeasures.

Insufficient Cleaning Efficiency

Insufficient cleaning efficiency is one of the most common problems in laser cleaning, which is usually manifested as slow cleaning speed, a lot of surface residue after cleaning, or uneven cleaning. The reasons for this problem include:

- Incorrect laser parameters: The core parameters of laser cleaning, such as pulse energy, wavelength, pulse duration, and beam diameter, will directly affect the cleaning effect. If the pulse energy is too low, the energy density of the laser is not enough to effectively remove the contaminants, resulting in incomplete cleaning. If the pulse energy is too high, although the contaminants can be removed, it may also cause damage to the substrate, especially for more brittle materials.

- Beam quality issues: The beam quality of the laser directly affects the cleaning efficiency and cleaning quality. Uneven beams or unstable focus will cause the laser energy to be unable to focus on the contaminants, reducing the cleaning effect. In addition, the inconsistency of the beam profile will also make the cleaning area uneven, causing some areas to be over- or under-cleaned.

- Surface contaminant type: Different types of contaminants have different absorption rates for lasers. For example, there are large differences in the absorption rates of metal oxide layers, grease, paint layers, etc. Some contaminants are easier to vaporize under the action of high-energy lasers, while others require specific parameters to improve cleaning efficiency. Choosing the appropriate combination of laser parameters is critical for dealing with different contaminants.

Thermal Damage to Substrate

Since laser cleaning uses a high-energy laser beam to act on the material surface, improper operation may cause thermal damage to the substrate surface:

- Surface melting or warping: When the laser power is set too high or the cleaning time is too long, the surface temperature of the material will rise rapidly, which may cause the surface layer to melt or deform, especially for heat-sensitive materials such as metals or plastics. This thermal effect will affect the physical properties of the material and even cause structural damage.

- Microcrack formation: For some brittle materials (such as ceramics, glass, etc.), the high temperature of laser cleaning may cause microcracks, especially under repeated cleaning or long-term high power. Microcracks not only affect the appearance, but also may weaken the mechanical strength of the material, resulting in a shortened service life.

High Operating Costs

The high operating cost of laser cleaning equipment is usually one of the important factors that users are concerned about. These costs mainly come from the following aspects:

- Energy consumption: Laser cleaning equipment consumes a lot of energy when working at high power, especially when cleaning large areas and heavy pollutants. The energy demand of the equipment may lead to an increase in operating costs. Especially in high-frequency usage scenarios, the cost of energy consumption will be more significant.

- Maintenance and repair costs: Laser cleaning equipment contains multiple precision components, such as laser optics, laser sources and cooling systems, etc. These components require regular maintenance to ensure the normal operation of the equipment. Especially optical components and laser sources are easily damaged under long-term high-power operation, and the replacement cost is high. In addition, the maintenance of the cooling system is also critical. If the cooling system fails, the laser cleaning equipment may shut down due to overheating.

คำถามเพื่อความปลอดภัย

The laser cleaning process involves the use of high-power lasers. Improper operation will cause safety hazards to operators and the environment, mainly in the following aspects:

- Eye and skin damage: The high-energy laser generated during laser cleaning is directly harmful to the skin and eyes, especially to the operator’s eyes, and exposure to the laser may cause permanent damage. Therefore, operators must wear laser protective glasses and protective gear that meet standards and comply with safety regulations.

- Smoke and particle emissions: During laser cleaning, pollutants vaporize at high temperatures and form smoke and tiny particles. If these gases and particles are not removed in time, they may affect the air quality and have an adverse effect on the health of the operator. For this reason, it is particularly important to be equipped with an effective smoke extraction and filtration system.

ความเข้ากันได้ของวัสดุมีจำกัด

The applicability of laser cleaning is closely related to the material properties. Not all materials are suitable for laser cleaning. The following materials have limited application effects in laser cleaning:

- Reflective surfaces: Highly reflective materials, such as aluminum and stainless steel, have a high reflectivity to laser energy, and most of the laser energy is reflected back to the equipment, reducing cleaning efficiency. In addition, these reflected energies may cause damage to the internal optical components of the laser cleaning equipment.

- Transparent materials: such as glass or some plastics, absorb less laser energy, and it is difficult for the laser energy to effectively act on the contaminant layer, resulting in poor cleaning results. In this case, a specific wavelength or pretreatment process is required to improve the cleaning effect.

Equipment Downtime

Laser cleaning equipment may occasionally stop due to technical problems during use, causing production delays. Here are some common reasons for downtime:

- Laser source failure: The laser source is the core component of the laser cleaning equipment. If the laser source fails, it needs to be repaired or replaced by professionals, which may cause a long downtime and increase operating costs.

- Cooling system failure: Laser cleaning equipment generates a lot of heat when working at high power, so the cooling system is crucial. If the cooling system fails or is improperly maintained, the equipment may overheat and automatically shut down, affecting the cleaning process.

Understanding and effectively solving these common problems of laser cleaning machines is of great significance for improving cleaning efficiency, reducing equipment operating costs, and ensuring safe use.

Troubleshooting and Preventive Measures

To ensure efficient and safe operation of laser cleaning machines, it is key to develop a reasonable fault prevention and handling strategy. This not only helps improve cleaning efficiency but also extends the life of the equipment and ensures the safety of operators. The following are some common fault prevention and handling suggestions, covering laser parameter optimization, regular maintenance, safety protocols, material compatibility testing, and operator training.

การปรับพารามิเตอร์เลเซอร์ให้เหมาะสม

According to the material and type of contaminants of the cleaning object, it is an important part of the laser cleaning process to reasonably adjust the laser parameters to achieve the ideal cleaning effect. Parameter optimization can effectively improve the cleaning efficiency, reduce the damage to the substrate, and ensure a uniform cleaning effect.

- Pulse duration: By properly adjusting the duration of the laser pulse, the heat diffusion on the material surface can be controlled, the heat-affected zone on the substrate can be reduced, and possible melting or microcracks can be prevented. Shorter pulse durations are usually suitable for sensitive materials, while longer pulse durations are helpful for thick contaminants.

- Pulse energy: The pulse energy level should be selected according to the type of contaminant and material to ensure thorough cleaning. Lower pulse energy may not be able to effectively remove contaminants, while too high energy will damage the substrate. Especially for metal surfaces with thick oxide layers, the energy range should be adjusted to avoid secondary processing.

- Repetition rate and wavelength: The characteristics of the material determine the optimal repetition rate and wavelength of the laser. For example, metal materials often require a higher repetition rate, and the wavelength should match the absorption characteristics of the contaminant. This ensures better absorption of the contaminant and increases the cleaning speed.

- Beam profile: The uniformity of the cleaning effect depends largely on the uniformity of the laser beam. Optimizing the beam profile to make the beam distribution uniform and stable can not only avoid leaving marks on the cleaned surface but also avoid local overheating and improve the overall cleaning effect.

การบำรุงรักษาตามปกติ

The daily maintenance of the laser cleaning machine is directly related to the stability and service life of the equipment. Formulating a scientific maintenance plan and executing it regularly can effectively reduce the failure rate.

- Cleaning of laser optics: When exposed, optical components are easily contaminated with dust, oil and other impurities, resulting in a decrease in beam quality. Regular cleaning of optical lenses, lenses, and reflectors can maintain the intensity and clarity of the beam and ensure the cleaning effect.

- Cooling system inspection: The laser cleaning machine generates a lot of heat when working at high power, and the cooling system is responsible for regulating the temperature of the equipment. Regularly checking the cooling system to ensure its stable operation will help prevent damage to the laser source and other key components due to overheating.

- Component replacement: Some consumable parts (such as filters, coolants, fiber heads, etc.) need to be replaced in time when they reach the end of their service life or are worn to maintain equipment performance. Establish a spare parts inventory for key components to cope with emergencies and ensure equipment continuity.

Security Protocol

The laser cleaning process involves high-energy lasers, and the operation of the equipment requires strict safety regulations to ensure the safety of the operator and the working environment.

- Protective equipment: Laser cleaning may cause direct damage to the operator’s skin and eyes, so the operator needs to wear special goggles and protective clothing to prevent the laser from contacting the skin or directly entering the eyes to reduce the risk of accidental injury.

- Safety interlock device: The safety interlock device can effectively prevent misoperation, isolate the operating area from the laser source, prevent unrelated personnel from entering the cleaning area, and prevent the equipment from starting up by mistake.

- Smoke extraction system: The smoke and particulate matter generated by laser cleaning have an impact on air quality. Equipped with a suitable smoke extraction and filtration system, the concentration of particulate matter can be reduced, harmful substances can be prevented from entering the operator’s respiratory system, the air is clean and a healthy working environment can be ensured.

Material Compatibility Testing

The effect of laser cleaning is closely related to the material properties. Performing material compatibility testing before formal cleaning can effectively avoid adverse effects during the cleaning process and ensure cleaning quality.

- Reflectivity and transparency: The reflectivity and transparency of different materials have a great impact on the laser cleaning effect. For highly reflective materials (such as aluminum, stainless steel) and transparent materials (such as glass, plastic), the laser absorption effect of the material should be tested, and the laser wavelength or parameters should be adjusted to adapt to the material characteristics if necessary.

- Pretreatment: Some highly reflective or special materials can be pretreated before cleaning, such as adding an absorbent coating to increase the material’s absorption rate of the laser. This process can effectively improve the cleaning effect and ensure that the contaminant layer is effectively removed.

การฝึกอบรมและพัฒนาทักษะ

Skilled operators can not only effectively improve cleaning efficiency, but also reduce the risk of operating errors and equipment damage, so operator training and skills development are crucial.

- Operator training: Operators need to master the basic principles, operation procedures, parameter adjustment, and other knowledge of the equipment to ensure that each operation meets the standards. The training content should cover the correct operation of the equipment, laser parameter adjustment, and emergency handling of common faults.

- Skill development: With the advancement of laser cleaning technology, operators need to continuously improve their skills, learn new technologies and fault diagnosis methods to better cope with complex cleaning needs. Regular technical exchanges, special training and practical exercises can enable operators to complete cleaning tasks more efficiently and safely.

In summary, the above prevention and treatment measures provide reliable support for the efficient and safe operation of laser cleaning equipment. Through regular maintenance, parameter optimization, safe operation, material compatibility testing, and personnel training, the failure rate of laser cleaning machines can be effectively reduced and the performance and service life of the equipment can be improved.

สรุป

As an efficient and environmentally friendly cleaning solution, laser cleaning technology is widely used in industry, manufacturing, cultural relics protection, and other fields. However, in real-world applications, users may face challenges such as insufficient cleaning efficiency, equipment downtime, and material compatibility. Insufficient cleaning efficiency often results from improper laser parameter settings, beam quality issues, and differences in contaminant types. By optimizing the energy, duration, repetition rate, and wavelength of the laser pulse, cleaning results can be significantly improved. In addition, regular equipment maintenance and material compatibility testing will ensure the efficiency and reliability of the cleaning process.

Safety is also an important aspect of laser cleaning. The operation of high-energy lasers requires strict compliance with safety protocols to protect the safety of operators. AccTek’s laser cleaning machines incorporate multiple safety protection measures, such as safety interlocks and smoke extraction systems, to effectively reduce operating risks. At the same time, we provide detailed operating training to ensure that operators can master equipment usage skills and emergency response methods, thereby reducing potential failures.

In short, although laser cleaning technology faces many challenges, through effective preventive measures and the high-quality equipment and services provided by AccTek, companies can give full play to the important role of laser cleaning in various industries and promote more efficient and environmentally friendly production methods. We are committed to helping customers optimize the cleaning process and improve equipment reliability, thereby maximizing the cleaning effect and creating higher value for users.

ข้อมูลติดต่อ

- [email protected]

- [email protected]

- +86-19963414011

- หมายเลข 3 โซน A เขตอุตสาหกรรม Luzhen เมือง Yucheng มณฑลซานตง

รับโซลูชันเลเซอร์