The Evolution of Laser Cutting Technology: Recent Developments And Future Prospects

Laser-cutting technology has made significant advances in recent years, revolutionizing industries ranging from manufacturing and healthcare to aerospace and the arts. The precision, speed, and versatility of laser cutting make it an indispensable tool in modern production processes. In this article, we’ll explore the evolution of laser cutting technology, taking a closer look at the advances made in recent years and predicting improvements that may be coming in the future.

Table of Contents

The Evolution of Laser Cutting Technology

Laser-cutting technology was first developed in the 1960s. Initially, laser cutting was a slow and tedious process, mostly limited to laboratory settings. The CO2 laser generator, one of the first laser generators used for cutting, was bulky and required a lot of power. However, significant advancements have occurred over the decades to make the technology what it is today.

Early development

The earliest laser cutting systems were essentially focused beams that melted or vaporized materials. These systems are less practical for industrial use because they lack precision and power. The CO2 laser generator was first demonstrated in 1964, marking an important step forward in the development of laser-cutting technology. These laser generators emit light in the far-infrared range, allowing them to efficiently cut and engrave a variety of materials.

CO2 laser generator and its impact

CO2 lasers were widely adopted in the 1970s because of their ability to cut a variety of materials, including metal, plastic, and wood, with extremely high precision. However, these early carbon dioxide laser systems were limited by power and speed. Advances in laser tube technology and beam quality optimization have helped overcome some of these limitations, paving the way for more industrial applications.

Introduction to fiber lasers

One of the most important developments in laser cutting technology over the past two decades has been the introduction of fiber lasers. Fiber lasers utilize solid-state media and are significantly more energy efficient than traditional CO2 laser generators. It improves cutting speed, accuracy, and cost-effectiveness, especially when cutting thin materials. Fiber laser generators have become a game changer in industries such as automotive, aerospace, and electronics manufacturing.

Current Status of Laser Cutting Technology

As we stand on the brink of the Fourth Industrial Revolution, laser cutting technology has come a long way and is now an integral part of modern manufacturing processes. Current laser-cutting technology is characterized by a combination of precision, versatility, and automation.

Fiber laser cutting

One of the most significant advancements in recent years has been the rise of fiber laser cutting. Fiber laser generators use optical fiber as the gain medium and have many advantages over traditional CO2 laser generators. These advantages include exceptional efficiency, precision, and versatility.

- Superior efficiency: Fiber laser generators are more energy efficient and consume less power to complete the same cutting task, which can reduce operating costs and reduce environmental footprint.

- Precision: Fiber laser generators provide unparalleled precision to cut complex patterns and fine details with ease.

- Versatility: Fiber laser generators can cut a variety of materials, including metals, plastics, and composites, making them the first choice for many applications.

Increase power

Laser-cutting power and speed have improved significantly in recent years. Modern laser cutting systems can provide higher power, allowing faster cutting of thick materials. This enhanced functionality significantly improves the efficiency and productivity of the manufacturing process.

Material thickness and cutting speed

In recent years, significant advances have been made in cutting thicker materials at faster speeds. This is due to advances in laser source power, optics, and cutting-head technology. As a result, laser cutting can now be used in a wider range of industrial applications, such as shipbuilding and heavy machinery manufacturing.

Improve accuracy

Precision is a key aspect of laser cutting technology, and recent developments have resulted in significant advancements in the field. Beam shaping and delivery systems and advanced motion control make it possible to achieve extremely fine details and complex designs. This kind of accuracy is especially valuable in industries with extremely tight tolerances, such as aerospace and medical equipment.

Cut a variety of materials

One of the most important developments in recent years is the ability to cut a wide range of materials. Initially, laser cutting was primarily used for metals, but has now expanded to include non-metals such as plastics, ceramics, composites, and even organic materials. This versatility opens up new opportunities in industries such as fashion, electronics, and medical research.

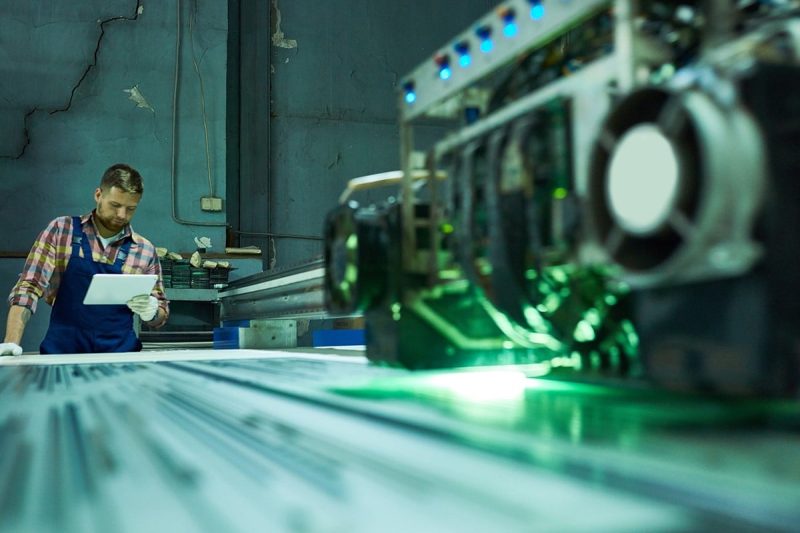

Automation and integration

Automation has become a fundamental aspect of laser-cutting technology. Robotic systems, computer numerical control (CNC), and advanced software streamline the manufacturing process. These systems can read design files and execute complex cutting patterns with minimal human intervention. Automatic loading and unloading as well as real-time monitoring and adjustment have become standard features of modern laser cutting systems. This automation not only reduces human intervention but also ensures consistent quality and productivity.

Industry 4.0 integration

The integration of laser cutting into Industry 4.0 initiatives is a game changer. Real-time data collection and analysis, coupled with the use of artificial intelligence and machine learning, makes laser cutting more efficient and adaptable. Predictive maintenance, process optimization, and adaptive control are now possible, reducing downtime and material waste.

Environmental considerations

In response to growing environmental concerns, laser-cutting technology has become more environmentally friendly. Fiber laser generators consume less energy and are inherently more environmentally friendly. Additionally, laser cutting systems are now designed with energy-saving features and often include filtration systems to reduce harmful emissions, making them a more sustainable option for manufacturers.

Improved security measures

Safety has always been an issue with laser cutting, mainly because of the high-intensity laser beams involved. Safety measures have improved significantly in recent years, including better housing designs, interlocking systems, and real-time monitoring of laser parameters. These advancements make laser-cutting operations safer for both the operator and the equipment.

Compact portable system

The miniaturization of laser cutting technology also makes it more accessible. Compact, portable laser cutters are now available, making this technology more accessible to small businesses, artists, and hobbyists. These systems are affordable and offer a level of precision previously unavailable to a wider audience.

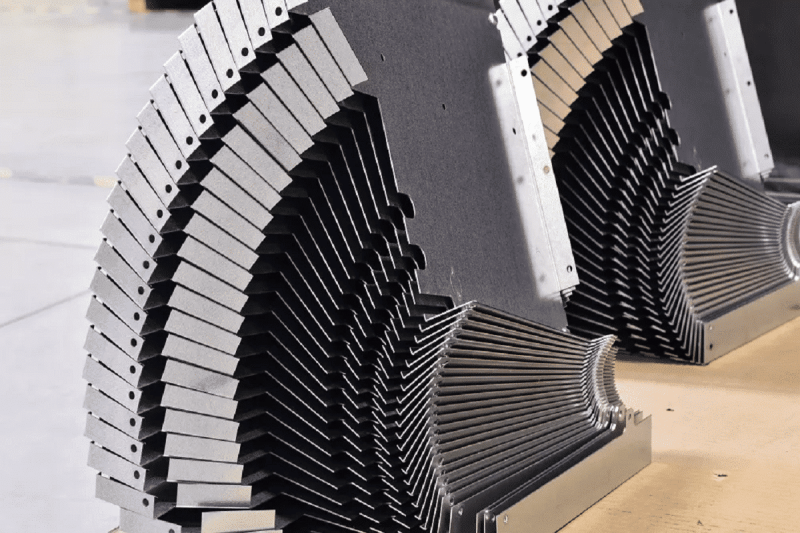

3D laser cutting

Traditional 2D laser cutting has expanded into the field of 3D laser cutting. This will enable the production of complex 3D components and structures, revolutionizing industries such as aerospace, automotive, and healthcare.

Nanosecond and femtosecond laser generators

Nanosecond and femtosecond laser generators are also making their mark in laser cutting. These ultrashort pulse lasers offer exceptional precision and minimal heat-affected zones, making them ideal for precision materials and micromachining processes.

Emerging Trends and Future Prospects

Looking to the future, laser-cutting technology will surely experience more breakthrough changes. Several emerging trends and technological advancements are expected to shape the landscape of laser cutting in the coming years.

Improve power and energy efficiency

Future laser-cutting systems are expected to offer higher power levels while maintaining or even improving energy efficiency. This will enable faster and more precise cutting of thicker materials, further expanding the range of applications.

Integration of artificial intelligence

The fusion of laser cutting with artificial intelligence (AI) and machine learning is set to revolutionize the industry. The AI-driven system optimizes cutting parameters, predicts maintenance needs, and adapts to changing workpieces in real-time, ensuring maximum efficiency and accuracy. Machine learning algorithms can also predict and prevent problems, reducing downtime and waste.

Hybrid laser cutting

Hybrid laser cutting systems that combine laser cutting with other processing processes such as milling or waterjet cutting will become more common. This approach allows for greater versatility and efficiency, especially when working with challenging materials.

Quantum laser cutting

Quantum technology is on the horizon, promising laser generators with unparalleled precision and energy efficiency. Quantum laser cutting can provide superior control at the atomic and molecular level, opening up new possibilities in materials processing, quantum computing, and other fields.

Space and extraterrestrial applications

As humanity expands its presence beyond Earth, laser-cutting technology will play a vital role in the fabrication and construction of space and other celestial bodies. It could be used to manufacture parts and tools on demand in extraterrestrial environments, reducing the need to transport heavy equipment from Earth.

Improved material processing

Laser-cutting technology will continue to evolve to accommodate new advanced materials, including those used in aerospace and healthcare. As new materials become available, the ability to precisely cut and shape these materials will open up new possibilities for innovation.

Sustainable development

Laser-cutting technology will continue to evolve to accommodate new advanced materials, including those used in aerospace and healthcare. As new materials become available, the ability to precisely cut and shape these materials will open up new possibilities for innovation.

Augmented reality (AR) assistance

AR is looking to get into the laser-cutting process. Operators can wear AR headsets that provide real-time information, guidance, and visual overlays to improve accuracy and simplify complex cutting tasks.

Integrate with additive manufacturing

Laser cutting and additive manufacturing (such as 3D printing) can complement each other. Combining these technologies enables the precise and rapid fabrication of complex structures, opening up new possibilities for product design. This integration is expected to gain traction in the aerospace, automotive, and healthcare industries.

Enhance connectivity and network security

As laser cutting technology becomes increasingly integrated with other manufacturing processes, the need for enhanced connectivity and strong cybersecurity measures will become critical. Protecting intellectual property and maintaining the reliability of laser cutting systems will be top priorities.

Adaptive laser system

The future of laser cutting lies in adaptive systems that can adjust in real-time based on the material being processed and the desired results. These systems will use artificial intelligence to optimize cutting parameters, ensuring maximum efficiency and quality.

Current Laser Cutting Applications and Industries

With recent advances in laser cutting technology, the range of applications and industries utilizing this technology have expanded significantly.

- Manufacturing: The manufacturing industry has witnessed changes in its processes thanks to laser cutting technology. From the precision cutting of metal parts in aerospace to the manufacturing of complex designs in consumer electronics, laser cutting has become an integral part of manufacturing a variety of products.

- Automotive: In the automotive industry, laser cutting is used to shape and trim parts. It offers high precision, allowing manufacturers to create complex shapes with minimal material waste. The technology will also help the automotive industry move toward lightweight, energy-saving vehicles.

- Electronics: In the electronics industry, demand for smaller, more complex components has driven the adoption of laser cutting. Laser cutting’s ability to precisely cut thin and delicate materials makes laser cutting critical for manufacturing circuit boards and complex electronic components.

- Healthcare: Laser cutting has had a major impact on medical devices, from stents and catheters to complex surgical tools. The high precision of laser cutting helps to precisely manufacture these life-saving and life-enhancing instruments. In addition, laser cutting is used to customize orthopedic implants, allowing for personalized healthcare solutions.

- Architecture and design: Laser-cutting technology has also found its way into art, architecture, and design. It allows the creation of complex and customized decorative elements, furniture, and even large structures, revolutionizing the design possibilities in these areas.

- Aerospace: In the aerospace industry, precision and material integrity are critical. Laser cutting plays a vital role in the manufacturing of aircraft and spacecraft components.

- Fashion and textiles: Even the fashion industry is starting to use laser cutting to create intricate patterns on fabrics, leather, and textiles. This technology brings new levels of creativity and customization to the world of fashion and clothing.

Challenges and Considerations

While the future of laser-cutting technology is bright, some challenges must be addressed. These challenges include safety issues, cost-effectiveness, and the need for skilled operators to manage advanced laser-cutting systems.

- Safety: Laser cutting involves high-intensity laser beams that can pose risks to the operator and the environment. Stricter safety regulations and continued research into laser safety measures can help mitigate potential hazards.

- Cost: Advanced laser cutting technology can require a significant initial investment. Manufacturers must carefully consider cost-benefit ratios and long-term savings when implementing these systems.

- Skilled labor: As the complexity of laser cutting systems continues to increase, there is a growing need for skilled operators and technicians who can effectively operate, maintain, and troubleshoot these machines.

Summarize

Laser-cutting technology has come a long way since its inception in the 1960s. From its humble beginnings, it has developed into an important part of modern manufacturing and is used in various industries. Recent years have seen rapid advances in fiber laser generators, speed, automation, safety, and environmental sustainability. These developments have expanded the range of applications and industries that benefit from laser cutting.

The future of laser cutting is bright. Integrating artificial intelligence, quantum technology, and augmented reality into the laser cutting process will push the boundaries of what is possible. Additionally, laser cutting’s role in improved materials processing, sustainability, and space exploration is expanding, further solidifying its relevance in the 21st century.

As we move forward, it is critical to address safety concerns, effectively manage costs, and develop a skilled workforce to harness the full potential of laser-cutting technology. With these factors in mind, the future of laser cutting is bright, promising to revolutionize the way we design and manufacture products, paving the way for a more efficient, precise, and sustainable manufacturing world.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions