Typical service life of CO2 laser tube

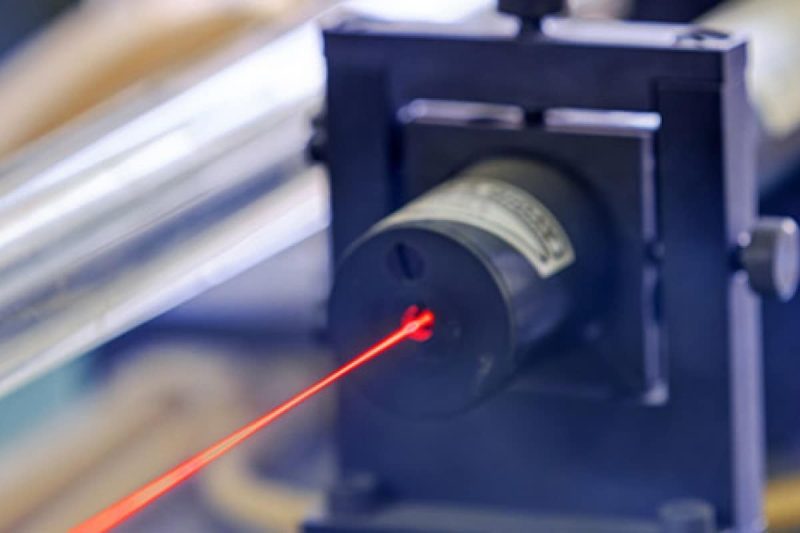

The CO2 laser tube is the core component of the CO2 laser cutting machine. Its basic structure and working principle directly affect the performance and stability of the cutting machine. In the basic structure:

- Glass tube: The glass tube of a CO2 laser tube is usually elongated and filled with a mixture of gases, including carbon dioxide (CO2), nitrogen (N2), and thin helium (He).

- Electrodes: The electrodes at both ends provide current through an external power source to form an electric field and excite gas molecules.

- Filling gas: The glass tube is filled with mixed gas. After the CO2 molecules are excited, an energy level transition occurs and laser light is generated.

The working principle is mainly based on the three-level energy level system:

- Electric field excitation: First, the electric field generated by the electrode excites the CO2 molecules to the excited state.

- Energy level transition: Excited CO2 molecules transfer energy to nitrogen molecules through collision, exciting the nitrogen to a high energy level.

- Laser radiation: When nitrogen molecules are de-excited, laser radiation is produced, with the main wavelength being 10.6 microns. This generated laser wavelength has better penetration for metal cutting by cutting machines, making it popular in industrial cutting applications.

Factors affecting the service life of CO2 laser tubes

Work environment factors

- Temperature: CO2 laser tubes are sensitive to temperature, and temperatures that are too high or too low may affect their performance. Maintaining the proper temperature within the specified operating temperature range helps extend the service life of the laser tube.

- Humidity: High humidity may cause water vapor to appear inside the laser tube, affecting laser production and tube wall stability. Maintaining proper humidity can help prevent this from happening.

- Air quality: A clean working environment helps reduce internal pollution of the laser tube and ensures stable laser output. Prevent dust and impurities in the air from entering the laser tube.

Effect of operating parameters

- Highly wear-resistant materials: Key components of laser welding machines require the use of highly wear-resistant and heat-resistant materials to ensure long-term stable operation of the equipment under high-temperature and high-energy laser irradiation. The cost of these materials is relatively high.

- Advanced automation control system: Advanced automation control system puts forward higher technical and material requirements for equipment manufacturing and maintenance, resulting in higher costs.

Maintenance and care

- Regular cleaning and inspection: Make sure the surface of the laser tube is clean, and regularly check whether there are dust, impurities, and other factors that affect the laser output. Regularly check the laser tube for damage or other abnormalities, and repair or replace it in time.

- Effectiveness of the cooling system: CO2 laser tubes usually need to be equipped with a cooling system. Keeping the cooling system in good operating condition is crucial to prevent the laser tube from overheating. Clean the buildup in the cooling system to ensure cooling effectiveness.

Working hours and frequency

- Continuous working time: Long-term continuous working may cause excessive wear of the laser tube. Arrange working hours reasonably in production to avoid overuse.

- Frequent start and stop operations: Frequent start and stop operations may have an impact on the laser tube and affect its life. Avoid unnecessary frequent start and stop operations.

Quality control and monitoring during production

- Carefully select working materials: Different materials have different degrees of wear on the laser tube. Choosing the appropriate materials can help extend laser tube life.

- Regular maintenance plan: Develop a regular maintenance plan, including cleaning, inspection, and replacement of key components, to ensure the long-term reliable operation of the CO2 laser tube and cutting machine.

Symptoms that the CO2 laser tube needs to be replaced

The service life of laser tubes is usually limited. Due to the influence of various factors, CO2 laser tubes may show some signs of needing to be replaced during use, including:

- Power decrease: The power of the CO2 laser tube gradually decreases with time of use. When the output power of the laser cutting machine is significantly weakened and affects work efficiency, it may be necessary to consider replacing the laser tube.

- Unstable laser output: If there is a problem inside the laser tube, such as gas leakage or tube wall damage, the laser output may become unstable, producing fluctuations or violent oscillations, which may be a sign of replacement.

- Frequent failures: If the laser tube has frequent failures and cannot maintain normal operation even after repairs, this may indicate that the laser tube has reached its life limit and needs to be replaced.

- Gas leakage: Gas leakage inside the laser tube may cause a reduction in laser output power and may also have adverse effects on other systems. Detected gas leaks may require the replacement of the laser tube.

- Contamination or damage to the tube wall: If the glass tube wall of the CO2 laser tube is contaminated or damaged, it will affect the transmission and stability of the laser.

- Reaching the rated service life: Each CO2 laser tube has its rated service life. Once it reaches or approaches this life, even if there is no obvious problem, it is recommended to consider replacing it to prevent sudden failure.

- Abnormal working temperature: CO2 laser tubes are sensitive to the temperature of the working environment. If the working temperature exceeds the normal range, the laser tube may be damaged.

- Taking these performances into consideration, users should regularly check the status of the laser tube when using a CO2 laser cutting machine. Once the above problems are discovered, take timely measures, including replacing the laser tube, to ensure the stability and efficiency of the equipment.

Methods to extend the service life of CO2 laser tubes

The life of the CO2 laser tube is a key factor affecting the overall performance of the laser cutting machine. Frequent replacement of CO2 laser tubes is costly and time-consuming. therefore, Extending the service life of CO2 laser tubes is key and can be achieved through the following methods:

- Properly set operating parameters: Set laser power, frequency, cutting speed, and material type appropriately to avoid excessive power and frequent start and stop operations to reduce wear of the laser tube.

- Maintain a good working environment: Ensure that the temperature, humidity, and air quality of the working environment are within the range where the laser tube can work normally. Avoid temperatures that are too high or too low. Maintain appropriate humidity to prevent water vapor from appearing inside the laser tube and affecting laser output. Keeping the work area clean helps prevent internal contamination of the laser tube.

- Regular cleaning and inspection: Clean the surface of the laser tube regularly to prevent the accumulation of dust and dirt. Regularly check the laser tube for damage or other abnormalities, and repair or replace it in time.

- Effectiveness of the cooling system: Ensure that the cooling system operates properly and maintains the laser tube within the appropriate temperature range. Clean buildup in the cooling system to maintain cooling.

- Avoid overuse: avoid long-term continuous work and arrange working hours reasonably to reduce the burden on the laser tube and delay the wear process.

- Carefully select working materials: Different materials have different degrees of wear on the laser tube. Choosing the appropriate material can help extend the life of the laser tube.

- Timely replacement of aging parts: Regularly replace the aging parts of the CO2 laser cutting machine, such as electrodes, to maintain the overall performance and stability of the equipment.

- Regular maintenance plan: Develop a regular maintenance plan, including cleaning, inspection, and replacement of key components, to ensure the long-term reliable operation of the CO2 laser tube and cutting machine.

Measures to deal with the end of life of CO2 laser tubes

When a CO2 laser tube approaches or reaches the end-of-life stage, it is crucial to take appropriate measures to ensure smooth operation and productivity of the equipment. The following are some measures to deal with the end-of-life of CO2 laser tubes:

- Establishment of an early warning system: Deploy a monitoring system to monitor the status of the CO2 laser tube in real-time. By detecting power, stability, and other key indicators, signs of laser tube performance degradation can be detected in advance so that timely measures can be taken.

- Regular performance evaluation: Conduct regular laser tube performance evaluation, and understand the wear and tear of the laser tube by testing and recording key parameters. This helps create a more effective maintenance schedule and timely replacement schedule.

- Consideration of alternatives: When the laser tube is nearing the end of its life, consider alternatives, such as replacing it with a new CO2 laser tube or upgrading to more advanced laser technology. This helps improve the performance and efficiency of your equipment.

- Preparation of spare laser tubes: Maintain a stock of spare laser tubes so that they can be quickly replaced when the CO2 laser tube reaches the end of its life and reduce production interruption time.

- Recycling and disposal of used laser tubes: Ensure the safe handling and recycling of used CO2 laser tubes. This not only helps the environment but also avoids potential safety risks.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.