Understanding the Radiation of Laser Cutting Machines

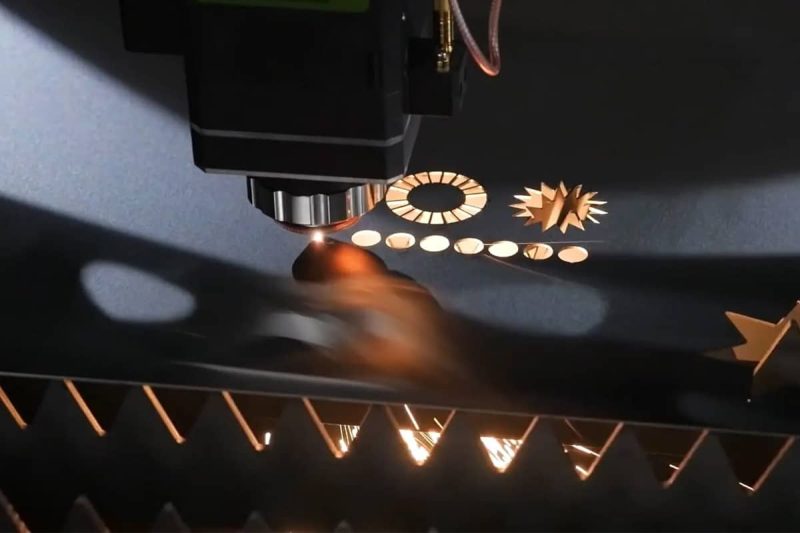

Laser cutting technology has been widely used in automotive, electronics, metal processing, and other industries due to its high efficiency and precise processing capabilities. Although laser cutting improves production efficiency and reduces material waste, the different types of radiation generated during its operation are worrying for equipment operators and managers, especially the health risks that may be caused by long-term exposure. Therefore, it is important to understand the types of radiation generated by laser-cutting machines and how to use them safely. This not only ensures the health of operators but also creates a safer working environment for enterprises.

This article will explore the characteristics of optical radiation, non-ionizing radiation, and ionizing radiation generated during the laser cutting process and their potential harm to the human body. At the same time, we will introduce the factors that affect radiation levels and provide regulations and standards to ensure that the company’s operations meet safety requirements. In addition, the article will share how to minimize the risk of radiation exposure through engineering control, administrative management, and personal protection measures. With this information, companies can not only improve safety awareness but also maintain efficient production while protecting the health of employees.

Table of Contents

Radiation Types of Laser Cutting Machines

Optical Radiation (Laser Beam)

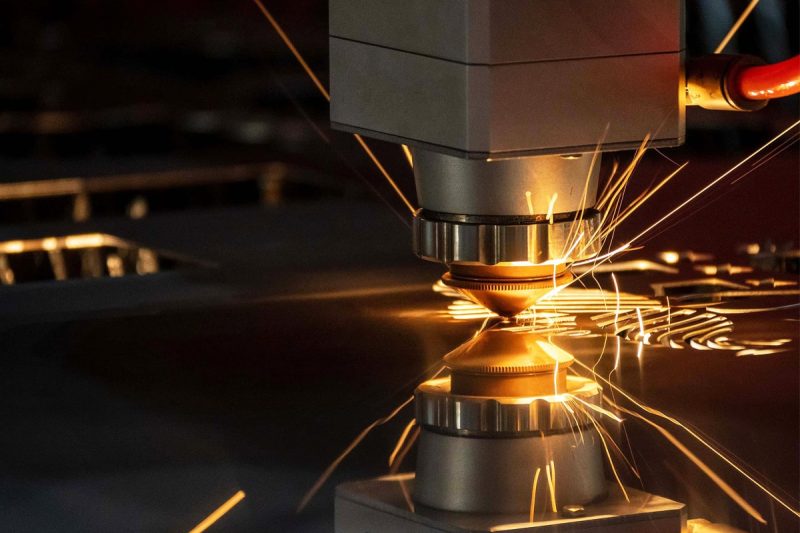

Laser cutting machines use high-energy laser beams to process materials. This laser beam is focused to form high-intensity light radiation that can melt, vaporize, or ablate materials. The energy of the laser beam is concentrated in a very small area, and the light radiation generated covers a wide range from infrared to ultraviolet, giving it excellent precision and efficiency in processing. By precisely controlling the laser beam, laser cutting machines can perform high-quality cutting, marking, and engraving on a variety of materials, and are widely used in manufacturing, automotive industry, aerospace, and other fields.

Features

- High energy concentration: The energy of the laser beam is highly concentrated in a small spot area, and this concentration enables the laser to cut or mark with extremely high precision. Due to the tiny diameter of the beam, laser cutting can achieve extremely delicate processing and is suitable for industrial applications requiring high precision.

- Strong penetration: The laser beam has strong penetration and can effectively penetrate various materials such as metals, plastics, glass and ceramics. The penetration ability of the laser enables it to process materials of varying thicknesses and achieve cutting and engraving of different depths.

- Wide spectral range: The wavelength range of laser light radiation ranges from infrared to ultraviolet, providing a wide range of adaptability to different materials and processing requirements. This flexibility in the spectral range enables laser cutting machines to be applied to a variety of industries and materials, including highly reflective materials and high melting point materials.

Potential Hazards

- Skin burns: Direct contact with the laser beam may cause severe skin burns. The high energy density of the laser can quickly increase the temperature and cause damage to skin tissue, which may cause permanent damage in severe cases. Therefore, when operating laser equipment, appropriate protective clothing must be worn to prevent direct skin exposure to laser radiation.

- Eye damage: The strong light of the laser beam may cause retinal burns, resulting in permanent damage to vision. Even indirect contact may cause short-term or long-term damage to the eyes due to scattered laser light. Therefore, when using laser equipment, operators must wear special laser protective glasses and ensure the safety of the working area.

- Long-term vision problems: Long-term exposure to laser radiation may cause eye fatigue, blurred vision, and other vision problems. Even in the absence of direct exposure to the laser beam, long-term scattered or reflected light may hurt vision. Therefore, regular eye examinations and proper work environment management are important measures to prevent vision problems.

Non-Ionizing Radiation (Infrared and Ultraviolet)

In the operation of some high-power laser cutting machines, especially when using high-energy laser generators under extreme conditions, a small amount of X-rays may be generated. X-rays are a type of ionizing radiation with sufficient energy to penetrate matter and produce ionizing effects. This usually occurs at high energy output or in special applications of laser systems, although in most laser cutting operations, the amount of X-rays generated is very limited.

Features

- High energy penetration: X-rays have extremely high penetrating power and can pass through thick materials, so X-rays generated in high-energy laser generators also have certain penetrating characteristics.

- Ionization effect: X-rays can ionize atoms or molecules in matter, producing charged particles. Ionization effects may have negative effects on biological tissues, including cell damage and genetic mutations.

- Special generation conditions: The generation of X-rays usually requires laser equipment to operate under extreme conditions, such as high power density or special laser wavelengths. Therefore, under standard operating conditions, the amount of X-rays generated is relatively low.

Potential Hazards

- Cell damage and cancer risk: The ionizing effect of X-rays may damage human cells and increase the risk of cancer. Ionizing radiation can damage the DNA structure of cells, cause gene mutations, and increase the risk of cancer.

- Long-term health problems: Long-term or high-dose X-ray exposure may cause serious health problems, including cell mutations, organ damage, and radiation sickness. High doses of radiation may also cause damage to internal organs and affect the normal function of the body.

- Exposure risk control: Although the X-ray dose generated during laser cutting is generally low, it is still necessary to be vigilant about its potential risks. Operators should pay attention to detecting and controlling possible X-ray leakage to ensure safety.

Health and Safety Considerations

Potential Health Risks

Exposure to laser-cutting machine radiation may bring a variety of health risks. First, direct contact with high-energy laser beams may cause skin burns. The high temperature and high energy of the laser can quickly increase the temperature of the skin, causing redness, swelling, pain, and even deep burns. Secondly, laser radiation is particularly harmful to the eyes, which may cause retinal burns or corneal damage, and in severe cases may cause permanent vision loss. In addition, long-term exposure to laser radiation may cause vision degeneration, and increase the risk of eye fatigue and blurred vision. The increased risk of skin cancer is also a concern. Long-term exposure to ultraviolet and infrared radiation may cause skin aging and the occurrence of malignant tumors. Cell damage is also one of the potential health risks, especially in high-energy laser operations, where ionizing radiation may damage cell DNA, causing mutations and cancer. Operators should have a full understanding of these risks and take necessary protective measures to ensure their health and safety.

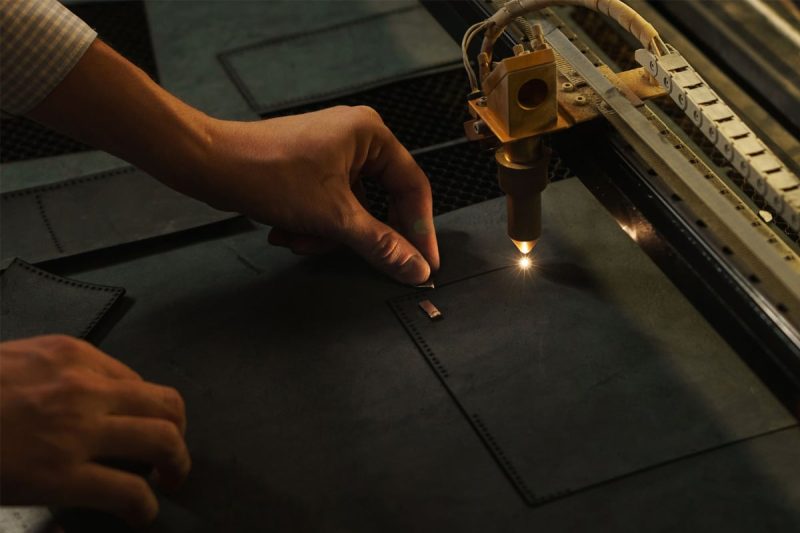

Importance of Implementing Safety Measures

Implementing safety measures is critical to reducing the risk of laser radiation. Protective barriers, such as laser shields and screens, can effectively block laser radiation and reduce the time operators are exposed to the laser beam. Personal protective equipment, such as laser safety glasses and heat-resistant coveralls, can provide operators with additional protection from direct exposure to laser beams and radiation. Regular maintenance and inspection of equipment is also an important part of safety management to ensure that the protective devices and safety systems of the laser cutting machine are operating properly. Equipment should be inspected and maintained regularly to detect and repair possible faults and ensure the effectiveness of protective measures. Through strict safety measures, the health risks of radiation to operators can be significantly reduced and a safe working environment can be created.

Occupational Health and Safety Regulations

Many countries and regions around the world have formulated occupational health and safety regulations related to laser radiation to protect the health of operators. For example, the US ANSI Z136.1 standard specifies safe operating specifications for laser radiation, clarifies protective measures and operating procedures, and aims to reduce the potential harm of laser radiation to workers. The European IEC 60825 standard also provides safety requirements for laser equipment, including equipment design, operating specifications, and radiation protection. Compliance with these regulations can ensure the safe operation of laser-cutting machines and reduce health risks to operators. By strictly following these occupational health and safety regulations, the health of operators can be effectively protected and the safety of the working environment can be maintained.

Factors That Affect Radiation Levels

Machine Settings and Parameters

The settings and parameters of the laser cutting machine have a direct impact on the radiation intensity and safety:

- Power: The power of the laser cutting machine determines the energy output of the laser beam. Although high power settings can improve cutting efficiency, they also increase the radiation intensity. Therefore, when performing cutting tasks, it is necessary to adjust the power setting of the laser according to the properties of the material and the processing requirements to ensure that while improving the cutting effect, the radiation risk is not excessively increased.

- Frequency: The frequency setting of the laser cutting machine affects the frequency of laser pulses. High-frequency settings may lead to more frequent laser pulse superposition, which will increase the radiation intensity and complexity. Therefore, the frequency should be adjusted reasonably according to the requirements of the processing task to balance the cutting effect and radiation control.

- Focal position: The focal position of the laser beam affects the concentration of laser energy and the cutting accuracy. The adjustment of the focal position not only affects the cutting quality but also affects the distribution and intensity of the radiation. When setting up the laser cutting machine, ensure that the adjustment of the focal position meets the operating requirements to achieve the best cutting effect and safety.

Exposure Time and Proximity to the Laser Cutting Process

The operator’s exposure time and proximity to the laser cutting process directly affects the radiation risk:

- Exposure time: The longer the operator is exposed near the laser cutting machine, the greater the possibility of radiation effects. To reduce the risk, the operator’s stay in the laser cutting area should be minimized to reduce long-term radiation exposure.

- Time close to the laser cutting process: During the laser cutting process, the operator should try to maintain a safe distance. Reducing the time and frequency of contact with the laser cutting area can reduce the potential risk of radiation. Adopting an appropriate rest and rotation system can also effectively reduce the operator’s radiation exposure.

Efficiency of Safety Functions and Muting Mechanisms

Safety features and shielding mechanisms of laser cutting machines are essential to protect the health of operators:

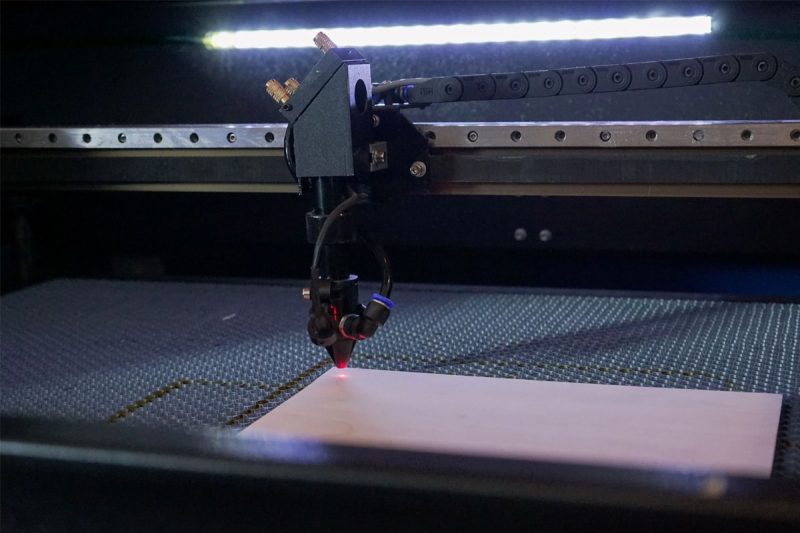

- Protective screens: Modern laser cutting machines are usually equipped with protective screens that can effectively isolate laser radiation and prevent the laser beam from directly contacting the operator. The design and installation of protective screens need to meet safety standards to ensure their effectiveness.

- Automatic shutdown mechanism: The automatic shutdown mechanism equipped with the laser cutting machine can automatically cut off the laser source when it detects an abnormality in the equipment or someone approaches the laser cutting area. This mechanism can quickly respond to potential safety threats and prevent accidental injuries.

- Safety lockout device: The safety lockout device prevents the laser cutting machine from starting when it is not ready or the safety check has not been completed. Make sure that the equipment is fully inspected before operation and that all safety measures are in place.

- Regular maintenance: Regularly check and maintain safety features and shielding mechanisms to ensure their continued effectiveness. Regular maintenance of equipment can detect and repair potential faults and ensure that all safety features are always in optimal condition, thereby effectively reducing radiation risks.

Laser cutting machine safety can be greatly improved to protect operators from potential radiation risks by optimizing machine settings, properly scheduling operator exposure times, and enhancing the efficiency of safety features and shielding mechanisms.

Regulations and Standards

Overview of Radiated Emission Regulations and Standards for Laser Cutting Machines

The manufacture and use of laser cutting equipment must comply with international and national radiation emission standards to ensure that radiation levels are within a safe range. These standards provide specific requirements and guidelines on laser radiation to protect the safety of operators and the surrounding environment. IEC 60825 is a laser equipment safety standard developed by the International Electrotechnical Commission (IEC), covering the classification of laser equipment, laser radiation protection measures, and operational safety requirements. This standard provides detailed safety specifications for the design, manufacture, and use of laser equipment to ensure that the equipment does not cause unnecessary radiation damage to personnel during operation.

In the United States, the ANSI Z136.1 standard is published by the American National Standards Institute (ANSI) and is a key guide for laser radiation safety. This standard specifies the use, operating specifications, and necessary protective measures of laser equipment to reduce the risks of laser radiation to operators and other personnel. It provides requirements for laser beam intensity, radiation area, warning signs, and personal protective equipment to ensure the safe operation and effective protection of laser equipment.

Compliance Requirements for Laser Cutting Equipment Manufacturers and Users

To meet these safety standards, laser cutting equipment manufacturers must strictly adhere to relevant regulations during the design and production process. Manufacturers need to conduct necessary testing and certification of equipment to ensure that it meets the requirements of standards such as IEC 60825 and ANSI Z136.1. This includes verification of the equipment’s radiation safety features, warning signs, shielding devices, and automatic safety mechanisms.

Users are also responsible for ensuring the safe use of the equipment when operating laser cutting equipment. Operators should receive relevant safety training to understand the correct use of the equipment and the radiation protection measures of the equipment. The training content usually includes basic knowledge of laser radiation, equipment operating specifications, emergency handling procedures, and the use of personal protective equipment. Ensuring that operators are familiar with this knowledge can help reduce radiation exposure and improve the safety of the working environment.

The Importance of Regular Inspections and Compliance Checks

Regular inspection and maintenance are important measures to ensure the safety of laser cutting equipment. Equipment should be inspected regularly according to the manufacturer’s recommendations and relevant standards to identify and repair potential safety hazards. This includes checking the effectiveness of the equipment’s shielding devices, protection systems, warning signs, and other safety features. Regular maintenance helps ensure that the equipment is always in optimal operating condition, reduces radiation risks, and extends the service life of the equipment.

Compliance inspections are a key link in ensuring that the equipment continues to comply with safety standards. By conducting compliance inspections, possible safety issues can be identified and all protective measures and safety features of the equipment are still working properly. This not only helps protect the health of the operator but also helps maintain the safe operation of the enterprise and comply with regulatory requirements. Regular compliance inspections and maintenance are important guarantees for preventing accidents and ensuring safety.

Radiation Safety Measures

Engineering Controls

- Housing: Equipping the laser cutting machine with solid housing is an effective measure to reduce radiation leakage. The housing should be designed by relevant safety standards and made of high-quality materials to prevent the laser beam and radiation from leaking outside the equipment. The housing should have good sealing performance and avoid any possible cracks or gaps, which may become potential channels for radiation leakage. Regularly check the integrity and safety of the housing to ensure that it can always effectively protect the radiation during the operation of the equipment, protecting the safety of the operator and the surrounding environment.

- Barrier: Setting up appropriate protective barriers is an important measure to protect operators from scattered laser radiation. The protective barriers should be designed according to the working characteristics and environmental conditions of the laser cutting machine to ensure that they can effectively block the scattered light and reflected light of the laser. The material of the barrier should have sufficient strength and durability and meet relevant safety standards. The height and position of the protective barrier should be reasonably planned to ensure that the operator is always outside the safe area during normal operation and reduce the risk of radiation exposure to other personnel.

Administrative Control

- Training: Operators should receive detailed radiation protection training to familiarize themselves with the safe operation specifications and protection functions of laser equipment. The training content should include basic knowledge of laser radiation, equipment operation procedures, radiation protection measures, emergency procedures, and how to properly use personal protective equipment. Regular training updates should be conducted to ensure that operators can master the latest safety operation skills and knowledge and improve their awareness and response capabilities to radiation risks. Training not only helps protect the health of operators but also improves work efficiency and reduces equipment failures.

- Signage: Clear warning signs around laser equipment can effectively remind operators and other personnel of radiation risks. These signs should use conspicuous colors and clear illustrations and text to ensure that all personnel can identify and understand the message conveyed by the sign. Warning signs should be placed in prominent locations in the laser cutting area and regularly checked and updated to ensure they remain visible at all times. The setting of signs can help improve operators’ safety awareness and avoid radiation damage caused by negligence.

Personal Protective Equipment (PPE)

- Safety glasses: Wearing protective glasses is a basic measure to protect the eyes from laser radiation. Protective glasses should comply with relevant safety standards and be able to effectively filter harmful light from laser radiation to prevent it from directly contacting the eyes. Choose the appropriate type of glasses and lens materials to adapt to lasers of different powers and wavelengths. The operator must always wear protective glasses during the laser-cutting process and check the condition of the glasses regularly to ensure that they are not damaged or ineffective.

- Gloves: Proper protective gloves can prevent direct contact between the skin and the laser beam and reduce radiation damage. Protective gloves should be made of materials that are resistant to high temperatures, cutting, and laser radiation to provide effective protection. When selecting gloves, their comfort and flexibility should be considered so that the operator can operate the equipment normally while wearing them. Gloves should be checked and replaced regularly to ensure that they maintain good protective performance. The use of protective gloves can reduce the risk of skin damage and radiation damage that may occur during laser cutting.

Summarize

As an efficient processing equipment, laser cutting machines have brought significant productivity improvement and processing accuracy to the manufacturing industry. However, along with its high efficiency comes radiation risks that cannot be ignored. Laser-cutting machines produce many types of radiation during operation, including optical radiation (such as laser beams), non-ionizing radiation (such as infrared and ultraviolet), and ionizing radiation (such as X-rays) that may be produced under extreme conditions. While these radiations improve cutting quality and efficiency, they can also cause potential harm to the operator and the environment.

To effectively reduce radiation risks, companies need to have a deep understanding of radiation types and their impact on health. Mastering the correct radiation protection knowledge and timely identifying and responding to various radiation risks is the basis for protecting the health and safety of operators. At the same time, companies must strictly comply with relevant regulations and standards, such as IEC 60825 and ANSI Z136.1, to ensure that equipment and operating processes meet safety requirements.

Implementing effective protection measures is key to reducing radiation risks. This includes equipping them with sturdy housing and appropriate protective barriers to prevent radiation leakage; providing comprehensive operator training and clear warning signs to enhance safety awareness; and using appropriate personal protective equipment, such as safety glasses and gloves, to protect operators from direct radiation damage. In addition, regular equipment maintenance and safety inspections are also necessary steps to ensure that the protection system is working properly, which helps to detect and repair potential safety hazards promptly.

By taking these measures in combination, companies can not only effectively reduce radiation risks, but also improve the safety of the working environment and production efficiency. The correct radiation protection strategy and equipment maintenance practices can help companies enjoy the advantages of laser-cutting technology while ensuring the health and safety of operators. This comprehensive safety management approach ensures that the laser cutting machine maintains a safe and healthy working environment while providing efficient processing.

Get Laser Solutions

Choosing the right fiber laser cutting machine can help optimize power consumption and achieve high operational efficiency. Working with a trusted supplier ensures access to advanced technology, tailored advice and ongoing support. At AccTek Laser, we offer a comprehensive range of laser cutting equipment designed to meet a variety of industrial needs. Our experts can help you choose the most energy-efficient model and configuration, taking into account factors such as material type, thickness and production volume. We also offer cutting-edge features such as smart cooling systems and energy management software to maximize performance and minimize energy use. In addition, our team provides scheduled maintenance services and 24-hour technical support to keep your equipment at peak efficiency. By partnering with AccTek Laser, you can achieve significant energy savings, reduce operating costs and enhance your sustainability efforts. Contact us today to learn more about our innovative laser solutions and how they can benefit your business.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions