Ventilation And Extraction Requirements For Operating a Laser Cutting Machine

Laser-cutting technology has revolutionized various industries, providing unparalleled precision and efficiency. However, the safe operation of laser-cutting machines requires attention to ventilation and extraction requirements. Laser-cutting machines produce smoke, dust, and potentially harmful by-products that need to be managed to ensure a safe and healthy work environment. In this article, we will explore the specific ventilation and extraction requirements necessary for the safe operation of a laser-cutting machine.

Table of Contents

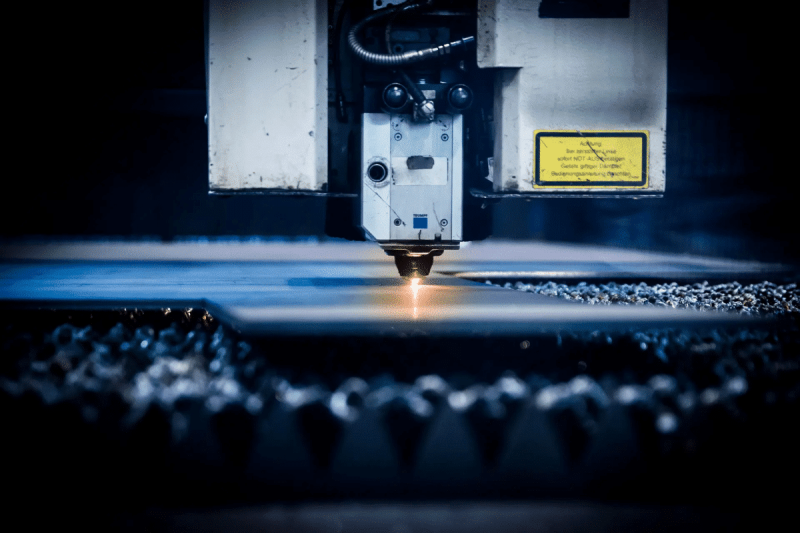

How the laser cutting machine works

Before we dive into ventilation and extraction requirements, let’s first understand how laser-cutting machines work. A laser-cutting machine is a device that cuts materials with a high-energy laser beam. It uses the high energy concentration of the laser beam to focus and scan the material surface. The heated surface quickly evaporates, melts, or burns, and is processed into the required shape and pattern, thereby completing precise cutting and engraving of the material.

The process of generating this high-energy laser beam will release a large amount of smoke, gas, and particles. Some of the smoke is harmful and poses a potential threat to the operating environment and the health of operators. Whether you’re working in a garage, an insulated shed, or a room in your home, having an effective ventilation and extraction system is critical to your health, equipment longevity, and laser projects.

The Importance of Ventilation and Exhaust Systems

The importance of the ventilation and exhaust system of the laser cutting machine cannot be ignored. They play a key role in the laser cutting process, mainly including the following aspects:

Emission of hazardous substances

Laser-cutting machines produce a large amount of smoke, gas, and particles during operation. These emissions include but are not limited to harmful gases, metal vapors, oxides, etc. The main function of ventilation and exhaust systems is to quickly remove these hazardous materials from the work area to reduce operator exposure.

Maintain indoor air quality

Ventilation and exhaust systems help maintain indoor air quality by effectively removing harmful emissions. This is critical to operator health, as the accumulation of harmful substances can lead to respiratory problems and other health risks.

Prevent fires and explosions

During the laser cutting process, flammable gas may be generated, which may cause fire or explosion if not eliminated in time. Ventilation and exhaust systems help remove these gases quickly, reducing the risk of fire and explosion.

Protective equipment

Emitted fumes and particles may adhere to the laser cutting machine’s optical components and lenses, reducing the performance and life of the equipment. By excluding these particles, ventilation and exhaust systems can extend the life and stability of equipment.

Comply with regulations and standards

Many countries and regions have regulations and standards on workplace safety and environmental protection, which require proper ventilation and exhaust systems for laser cutting machine operations. It is recommended to comply with these regulations and standards to avoid legal issues and fines.

Specific Requirements For VentilAtion and Extraction Systems

The ventilation and exhaust system of the laser cutting machine is very important to ensure the safety and efficiency of the operating environment. These systems have specific requirements that can vary slightly depending on the type and use of the laser cutter, but generally include the following general requirements:

Specific needs of ventilation systems

Key considerations for laser cutting machine ventilation requirements are:

- Smoke and gas emissions: The operation of a laser cutting machine produces large amounts of smoke and harmful gases such as carbon dioxide and carbon monoxide. These emissions need to be effectively discharged from the work area to prevent them from accumulating indoors and posing a health hazard to operators.

- Air quality maintenance: Ventilation systems should have filtering and cleaning capabilities to ensure that exhaust air is safe and free of harmful substances. This helps maintain indoor air quality and reduces operator exposure to hazardous substances.

- Negative pressure system: Ventilation systems are usually designed with negative pressure to ensure that indoor air does not flow to other work areas. This helps prevent hazardous materials from spreading to other parts and maintains the safety of the entire work environment.

- Ventilation system location: The location of the ventilation system should take into account the laser cutter’s operating area to maximize the capture and discharge of harmful emissions. The location and number of vents need to be determined based on the size and power of the laser-cutting machine.

- Emergency handling: The ventilation system should have emergency handling capabilities to deal with possible gas leaks or smoke accumulation. This includes alarm systems, emergency shutdown devices, etc.

Specific needs of extraction systems

The following are key considerations for laser cutting machine air extraction requirements:

- Extraction efficiency: The extraction system must have efficient extraction capabilities to ensure the rapid discharge of smoke and harmful gases. This helps maintain the cleanliness of the operating environment and the health of the operators.

- Filtration and purification: Extraction systems often include filtration and purification devices to remove harmful substances from the exhaust air. This helps reduce negative impact on the environment and protects operator health.

- Negative pressure design: Like ventilation systems, extraction systems should also be designed with negative pressure to ensure that harmful emissions do not spread to other areas.

- Regular maintenance: Extraction systems require regular maintenance to ensure they function properly. This includes things like filter changes, cleaning, and system checks.

- Noise control: Extraction systems can be noisy and steps need to be taken to reduce noise levels to improve the comfort of the operating environment.

Selection of Ventilation and Extraction Systems

Choosing a laser cutting machine’s ventilation and extraction system is critical because these systems directly affect the safety and efficiency of the operating environment. Here are some guidelines to help you choose the right ventilation and extraction system:

- Consider laser cutting machine type and power: Different types and powers of laser cutters produce different types and amounts of exhaust gases and fumes. Make sure the ventilation and extraction system you choose is suitable for your specific laser-cutting machine.

- Follow manufacturer recommendations: Manufacturers often provide specific ventilation and extraction system requirements and recommendations to ensure system safety and performance.

- Consider the exhaust volume: The exhaust volume of the ventilation system should be large enough to effectively remove exhaust gas and smoke. Ensure that the exhaust air volume of the system can meet the needs of the laser cutting machine.

- Filters: Choose an extraction system with high-efficiency filters to remove harmful gases and particles. The type and quality of filters are crucial to the treatment of exhaust gases.

- Control system: Choose an air extraction system with an adjustable control system to adjust the air extraction intensity according to the needs of the laser cutting process. This helps improve system efficiency and save energy.

- Noise control: If noise is an important consideration, select a system with noise control measures to reduce noise levels during operation.

- Safety: Ensure ventilation and extraction systems comply with local and national safety standards and regulations. This is vital to the health and safety of operators.

- Maintenance and cleaning: Consider the maintenance needs of your system and ensure regular cleaning and maintenance to maintain its performance.

- Budget: Choose the right ventilation and extraction system based on your budget. While quality and performance are often related to cost, ensure that the quality and safety of the system are not sacrificed.

- Consult a professional: If you’re not sure how to choose the right ventilation and extraction system, it’s best to consult a professional engineer or supplier who can provide customized advice based on your specific needs.

Installation of Ventilation and Extraction System

Installing a ventilation and extraction system for a laser cutting machine requires caution to ensure system effectiveness, operational safety, and compliance with regulations. The following is a general guide to the installation steps of ventilation and extraction systems:

- Determine the installation location: Determine the best location for the ventilation and extraction system. It should usually be located near the laser cutting machine to maximize the capture of exhaust gases and smoke. Consider the location of the air inlets of the ventilation and extraction systems to ensure that the system has normal air circulation and avoids negative pressure in the room.

- Safety and regulations: Before installation, be sure to understand and comply with local and national safety standards and regulations to ensure the legal operation of the system. If a license or approval is required, make sure you obtain the necessary documentation before installation.

- Install air extraction system: Install air extraction equipment and pipes to guide waste gas to the air extraction equipment. Make sure ducts are airtight and oriented correctly to effectively capture exhaust gases and smoke. Install high-efficiency filters to remove harmful gases and particles to ensure the exhaust is safe.

- Electrical connections: Install electrical connections for ventilation and extraction systems to ensure proper system operation. Follow the manufacturer’s electrical connection guidelines.

- Control system: A control panel or controller that installs the system so that the operation of the ventilation and extraction system can be adjusted as needed.

- Noise control: If noise is a problem, take appropriate steps to reduce it, such as installing sound-absorbing materials or soundproof enclosures.

- Testing and adjustment: Before officially using the laser cutting machine, test and adjust the ventilation and exhaust system to ensure that its performance meets the requirements.

- Maintenance: Establish a regular maintenance schedule, including tasks such as cleaning and changing filters, to maintain system effectiveness.

- Training: Train operators on the proper use of ventilation and extraction systems to ensure safe operation.

Summarize

Setting up your laser exhaust system is critical to your health and the health of your laser engraver. If the exhaust system is not working, the air quality in your workplace will immediately decrease and smoke odors will begin to build up and fill your premises. Depending on the materials you are laser-cutting, the smell and toxic smoke from the laser-cutting machine may enter your lungs. Proper ventilation and extraction systems can effectively exclude smoke, gases, and harmful substances, maintain the cleanliness of the operating environment, and reduce the risk of Negative impact on the environment. In addition, operator training and compliance with relevant regulations and standards are also key factors in ensuring the safety of laser-cutting machine operations. By considering these factors, we can ensure that our laser-cutting machines work efficiently while maintaining the health and safety of the environment and operators.

If you are considering purchasing a laser cutting machine or need assistance with ventilation and extraction solutions, don’t hesitate to contact AccTek Laser. Our team is here to help you make an informed decision and ensure a safe, efficient, and compliant laser-cutting operation. Investing in a laser cutting machine is a significant step for your business, and understanding ventilation and extraction requirements is vital. AccTek Laser is your partner in achieving the best results. Contact us today to learn more about our solutions and how we can assist you in your laser-cutting journey.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions