What Are The Advantages And Disadvantages of Fiber Laser Marking Machines?

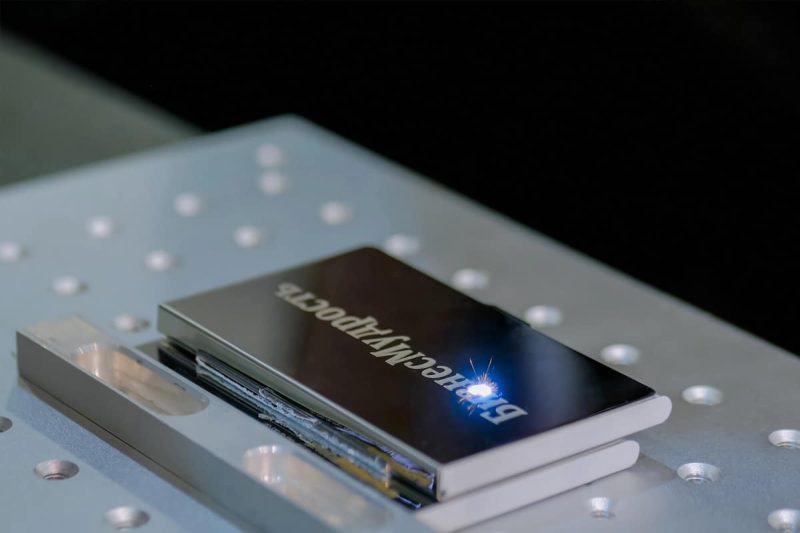

Fiber laser marking machines have revolutionized the way industries permanently mark their products. This technology uses a high-intensity laser beam, generated through an optical fiber medium, to create precise and durable marks on a wide range of materials, including metals, plastics, and ceramics. With unparalleled precision, speed, and versatility, fiber laser marking systems have become essential tools in sectors such as automotive, electronics, medical devices, and aerospace. They provide permanent, high-contrast markings that ensure traceability, branding, and regulatory compliance. However, while fiber laser marking offers many advantages, such as low maintenance and high efficiency, it also comes with certain limitations, including high initial costs and challenges with certain materials. This article explores the various advantages and disadvantages of fiber laser marking machines, offering insights that help businesses weigh their benefits against potential limitations to make informed decisions.

Table of Contents

Understanding Fiber Laser Marking Machines

What Is a Fiber Laser?

A fiber laser is a type of solid-state laser that uses an optical fiber as the active gain medium, doped with rare-earth elements such as ytterbium, erbium, or neodymium. Unlike gas or crystal-based lasers, fiber lasers utilize the flexibility and efficiency of optical fibers, allowing for a compact, reliable, and energy-efficient design. Fiber lasers are known for their excellent beam quality, high power density, and ability to produce precise, high-contrast markings on a wide range of materials. This makes them a preferred choice for industrial marking applications where precision and durability are critical.

Working Principle of Fiber Laser Marking Machine

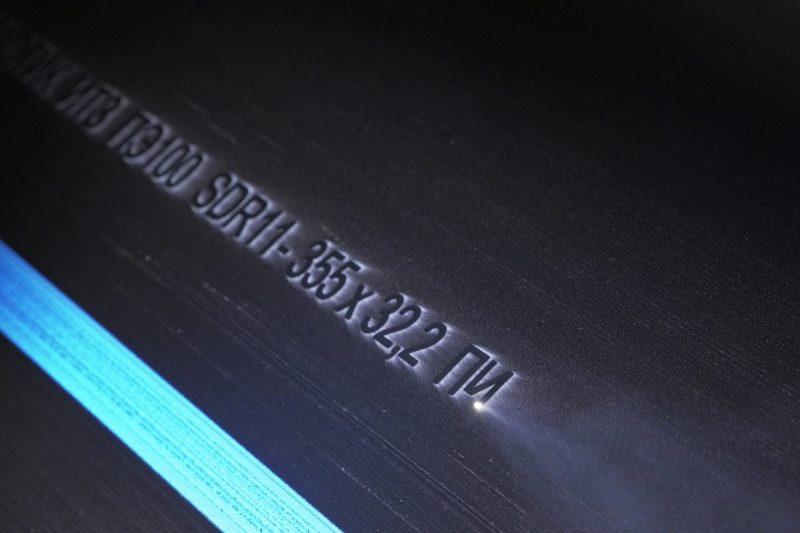

The fiber laser marking process begins with the generation of a high-intensity laser beam by stimulating the doped fiber with a pump diode. The resulting laser light is then guided through optical fibers to reach the marking head. A galvanometer system, consisting of mirrors that move with high speed and precision, directs and focuses the laser beam onto the surface of the workpiece. The interaction between the laser and the material results in a permanent mark, which can take the form of text, images, barcodes, or other symbols. Depending on the laser’s settings and the material being marked, the process can create different effects, including engraving, etching, annealing, and discoloration. The process is contact-free, highly accurate, and fast, making it ideal for various industrial needs.

Common Applications

Fiber laser marking machines are used across diverse industries due to their versatility, speed, and precision. Common applications include:

- Automotive Industry: Marking of components such as engine parts, chassis numbers, and serial codes for traceability and anti-counterfeiting.

- Medical Devices: Permanent markings on surgical instruments, implants, and other medical tools to ensure compliance with regulatory standards.

- Electronics and Semiconductors: Marking circuit boards, microchips, connectors, and enclosures with critical data for identification and quality control.

- Jewelry and Luxury Goods: Creating intricate and decorative engravings on metals, such as gold and silver, for personalized designs.

- Aerospace and Defense: Durable, legible markings on high-performance parts that can withstand harsh conditions and extreme temperatures.

- Packaging Industry: Marking product information, barcodes, and expiration dates on various packaging materials to ensure product traceability and compliance.

By offering unparalleled precision and versatility, fiber laser marking machines continue to play a pivotal role in enhancing product traceability, branding, and regulatory compliance in numerous sectors.

Advantages of Fiber Laser Marking Machines

High Precision and Quality

Fiber laser marking machines are known for their ability to produce high-precision markings with exceptional beam quality. The small focal diameter and stable output result in intricate, detailed, and high-resolution markings with smooth edges and minimal thermal distortion. This precision allows for complex patterns, fine text, micro-markings on electronic components, and highly detailed graphics, even on small or delicate surfaces. The consistent beam quality ensures that every mark is clear, crisp, and professional, meeting the rigorous standards of industries like aerospace, electronics, and luxury goods.

Speed and Efficiency

One of the key strengths of fiber laser marking machines is their speed. These systems can mark rapidly, achieving high throughput rates ideal for mass production and high-volume operations. The high power density and fast modulation capabilities of fiber lasers allow them to deliver accurate marks in seconds, reducing overall cycle times. This speed not only boosts productivity but also lowers per-unit marking costs, making fiber laser marking highly efficient for manufacturers looking to optimize their processes and meet tight deadlines.

Consistency and Repeatability

Fiber laser marking machines deliver consistent, repeatable results, even in large production runs. The stability of the laser output ensures that each mark, regardless of batch size, maintains the same high level of quality and precision. This repeatability is vital for industries where consistency is a key component of brand integrity, regulatory compliance, and quality assurance.

Durability and Longevity of Marks

Marks created by fiber laser machines are permanent and exhibit exceptional durability. They are resistant to wear, fading, corrosion, high temperatures, and harsh environmental conditions. This durability ensures that product markings, such as serial numbers, barcodes, or logos, remain legible throughout the product’s lifecycle, even when exposed to extreme conditions. This characteristic is crucial for industries like automotive, aerospace, and medical devices, where traceability and regulatory compliance are paramount, and markings must endure over time without degradation.

Versatility in Material Compatibility

Fiber laser marking machines can mark a wide array of materials, providing unmatched versatility across different applications. These materials include:

- Metals: Stainless steel, aluminum, brass, copper, titanium, gold, silver, and other alloys.

- Plastics: ABS, polycarbonate, polyethylene, and other engineering-grade plastics.

- Ceramics and Glass (with specific coatings): For certain applications requiring specialized coatings or treatments.

- Organic Materials (with limitations): Such as wood and leather.

This versatility enables manufacturers to use a single marking system for diverse projects, reducing the need for different machines and simplifying workflows.

Low Maintenance and Operational Costs

The solid-state design of fiber lasers ensures minimal maintenance compared to other laser technologies. With no moving parts, mirrors, or consumables such as inks or chemicals, fiber lasers have low ongoing operational costs. Their typical lifespan often exceeds 100,000 hours of operation, providing long-term reliability and reducing the frequency of repairs or downtime. These attributes contribute to a lower total cost of ownership, making fiber laser marking an economically attractive option.

Energy Efficiency

Fiber laser systems boast high electrical-to-optical efficiency, often exceeding 30%. This level of energy efficiency translates into lower power consumption, which reduces operational costs and the overall environmental impact of manufacturing processes. For companies seeking to lower their carbon footprint while maximizing productivity, fiber lasers offer a compelling solution with energy-saving benefits.

Compact and Flexible Design

Fiber laser marking machines are compact and space-efficient, making them easy to integrate into various production settings, from small workshops to large industrial facilities. Their flexibility allows for both standalone operation and seamless integration into automated production lines. The compact size of fiber lasers does not compromise their power, ensuring they remain versatile tools for marking, engraving, and etching tasks across different industries.

Environmentally Friendly

Fiber laser marking is an environmentally conscious choice. It is a non-contact, non-chemical process that does not produce hazardous waste, such as fumes, inks, or solvents. This makes it a cleaner alternative to traditional marking methods that rely on consumables and generate waste. The absence of chemical emissions also contributes to safer and healthier working environments, reducing potential exposure risks for operators.

Non-Contact and Non-Mechanical Process

The laser marking process is non-contact, meaning it does not physically touch the workpiece. This characteristic eliminates mechanical wear and tear on the material being marked and avoids damage or distortion. The absence of physical contact also reduces the need for tool replacements, minimizing downtime and enhancing operational efficiency. Delicate or thin materials, in particular, benefit from this non-contact approach, ensuring precise markings without compromising structural integrity.

Automation and Integration Capabilities

Fiber laser marking systems offer advanced automation capabilities and can be easily integrated into existing production lines. With sophisticated control software, these machines support real-time monitoring, data entry, and parameter adjustment, enhancing their compatibility with modern Industry 4.0 practices. This capability allows for streamlined production processes, reduced human intervention, and greater production efficiency, particularly in large-scale manufacturing operations.

Enhanced Security Features

Fiber lasers can create complex and tamper-proof marks, including QR codes, barcodes, and intricate security patterns. These markings serve as effective anti-counterfeiting measures, enhancing product traceability and authentication across the supply chain. By incorporating unique identifiers, manufacturers can protect their brands, reduce the risk of counterfeiting, and maintain consumer trust.

The numerous advantages of fiber laser marking machines, ranging from their precision and efficiency to environmental sustainability, make them indispensable for modern manufacturing. Their versatility, low operational costs, and durability have propelled their adoption across various industries, where reliability and consistent high-quality markings are critical to business success.

Disadvantages of Fiber Laser Marking Machines

High Initial Investment

One of the primary drawbacks of fiber laser marking machines is their high initial cost. The advanced technology, precision components, and powerful laser sources contribute to a significant upfront investment, which may be challenging for small businesses or startups to afford. While the long-term cost savings and efficiency benefits often justify this expense, the barrier to entry remains a consideration for many manufacturers.

Material Limitations

While fiber laser marking machines are highly versatile, they are not suitable for all materials. They perform exceptionally well on metals, some plastics, and ceramics but struggle with certain transparent materials, untreated glass, and organic materials like wood in some cases. For applications requiring marking on these types of substrates, alternative laser technologies, such as CO2 lasers, may be more appropriate.

Safety Considerations

Operating a fiber laser marking machine requires adherence to stringent safety protocols. High-powered laser beams pose potential hazards, including skin burns and eye injuries. Proper safety measures, such as protective eyewear, enclosures, and operator training, are critical to ensuring a safe working environment. Failure to observe safety guidelines can lead to serious accidents, increasing liability risks for businesses.

Requirement for Skilled Operators

Despite the possibility of automation, fiber laser marking machines often require skilled operators to set up, calibrate, and maintain optimal performance. Operators must understand laser parameters, marking software, and safety protocols to achieve the desired marking quality and efficiency. Training requirements may increase labor costs and limit the immediate availability of qualified personnel.

Limited Color Marking

Fiber lasers typically produce monochromatic markings, which can limit their aesthetic appeal for certain applications. While specific processes may generate colors on materials like titanium, achieving consistent, vibrant, multi-color markings is challenging. This limitation makes fiber lasers less suitable for applications requiring colorful, decorative, or branding elements that demand multiple hues.

Thermal Effects on Materials

The high energy density of fiber lasers can lead to thermal effects on certain materials during marking. These effects may include heat-affected zones, micro-cracking, or changes in material properties. While the impact is minimal for many applications, heat-sensitive materials may suffer, necessitating adjustments in laser parameters or the use of alternative marking technologies to avoid damage.

Not Suitable for Deep Engraving

Fiber laser marking machines excel at surface marking but have limitations when it comes to deep engraving or cutting through thick materials. For applications that require significant material removal or deep etching, other laser types or mechanical methods may be more effective. The lack of deep-engraving capabilities restricts their utility for specific manufacturing needs.

Potential Safety Hazards

In addition to operator safety, there is a risk of laser beam reflection from highly reflective materials, such as polished metals. Reflected beams can pose a hazard to the laser system itself or nearby personnel if not properly controlled. Protective measures, such as specialized optics or coatings, may be necessary to mitigate these risks, adding complexity and cost to the setup.

Limited Field Size

The marking field size of a fiber laser machine is determined by the optics and scanner system. For applications that require marking on large surfaces, the limited field size may necessitate repositioning the workpiece or using specialized optics, potentially complicating and slowing down the marking process. For large-area applications, alternative marking systems with larger field sizes may be more suitable.

Possible Maintenance Costs

Although fiber lasers are generally low-maintenance compared to other laser systems, certain components, such as the galvanometer scanners, lenses, or cooling systems, may still require periodic maintenance. Dust, debris, and environmental factors can impact machine performance, necessitating periodic cleaning and servicing. While the frequency of maintenance is lower, these costs can add up over time, particularly in demanding production environments.

While fiber laser marking machines offer exceptional performance and versatility, their limitations and potential challenges should be carefully considered. By weighing these disadvantages against their numerous advantages, manufacturers can make informed decisions about whether fiber laser marking is the right choice for their specific needs and production goals.

Comparative Analysis with Other Marking Technologies

When evaluating the advantages and disadvantages of fiber laser marking machines, it is essential to compare them with other common marking technologies, such as CO2 laser marking machines, UV laser marking machines, and mechanical engraving systems. Understanding the differences, strengths, and limitations of each technology can help manufacturers make more informed decisions based on their specific marking needs.

CO2 Laser Marking Machines

CO2 laser marking machines use a gas mixture (carbon dioxide, nitrogen, and helium) as their laser medium, producing a laser beam in the infrared range. This type of laser is highly effective for marking organic and non-metallic materials.

Advantages Compared to Fiber Lasers

- Material Versatility for Non-Metals: CO2 lasers excel at marking and cutting non-metallic materials such as wood, glass, ceramics, textiles, acrylics, and certain plastics. This makes them ideal for applications in industries like packaging, woodworking, and textiles.

- Larger Field Size Options: CO2 lasers typically offer larger marking field sizes, making them suitable for marking or engraving on larger surfaces without repositioning the workpiece.

- Lower Initial Cost (for Low-Power Systems): For applications that do not require high precision or advanced features, CO2 laser systems may have a lower initial cost compared to fiber lasers.

Disadvantages Compared to Fiber Lasers

- Limited Metal Marking Capabilities: CO2 lasers struggle to mark metals unless treated with special coatings or additives. This limits their effectiveness in metal-based applications where fiber lasers excel.

- Lower Beam Quality and Precision: Compared to fiber lasers, CO2 lasers generally offer lower precision and beam quality, which can impact the marking detail and clarity on fine designs.

- Higher Maintenance Requirements: CO2 laser marking systems typically require regular maintenance, including mirror alignment and replacement of consumables such as gas, which increases operational costs.

UV Laser Marking Machines

UV (ultraviolet) laser marking machines operate at a much shorter wavelength compared to fiber and CO2 lasers, typically around 355 nm. The shorter wavelength results in a “cold marking” process with minimal thermal impact on materials.

Advantages Compared to Fiber Lasers

- Cold Marking with Minimal Heat Damage: UV lasers create marks with very little heat generation, making them ideal for marking heat-sensitive materials such as plastics, glass, and thin films. This minimizes the risk of material warping, burning, or discoloration.

- High-Contrast Marks on Plastics: UV lasers often produce high-contrast marks on a wide variety of plastics, which is valuable in industries like electronics and medical devices.

- Precise and Micro-Marking Capabilities: The small spot size of UV lasers allows for extremely precise and detailed markings, suitable for intricate designs and micro-marking on small components.

Disadvantages Compared to Fiber Lasers

- Lower Marking Speeds: UV laser marking is generally slower compared to fiber laser marking, which may not be suitable for high-volume production lines requiring rapid throughput.

- Higher Cost per Watt: UV lasers tend to be more expensive per watt than fiber lasers, leading to higher initial investments and potentially higher operating costs.

- Shorter Lifespan and Higher Maintenance Needs: UV laser sources typically have shorter lifespans and may require more frequent maintenance or replacement compared to the robust and durable fiber laser sources.

Mechanical Engraving

Mechanical engraving involves the use of a physical cutting tool, such as a rotary cutter or diamond tip, to remove material and create permanent marks. It is a traditional marking process used for a wide range of applications.

Advantages Compared to Fiber Lasers

- Deep and Physical Marking: Mechanical engraving produces deep and physical cut marks, providing exceptional durability. This makes it ideal for applications where tactile depth is important, such as signage, nameplates, and heavy-duty parts.

- Cost-Effective for Basic Needs: For simple marking and engraving needs, mechanical engraving machines may have lower initial costs compared to fiber laser systems, especially for basic setups.

Disadvantages Compared to Fiber Lasers

- Contact-Based Process: Mechanical engraving is a contact-based process, which can lead to wear on the tool and surface damage to delicate workpieces. The need for periodic tool replacements also increases maintenance costs.

- Lower Precision and Complexity: Compared to the precision and detail possible with fiber lasers, mechanical engraving often falls short, particularly for intricate designs and fine text.

- Slower Speeds and Limited Automation: Mechanical engraving processes are generally slower and less suited for high-speed, automated production lines. This can lead to longer processing times and lower productivity.

- Limited Material Compatibility: Mechanical engraving is less versatile in terms of material compatibility and may not work well with certain hard or brittle materials.

Each marking technology has its strengths and weaknesses, making it important to select the right solution based on specific application requirements. Fiber laser marking machines stand out for their high precision, versatility, and durability, making them suitable for a broad range of materials, especially metals and select plastics. While CO2 and UV laser marking machines excel in areas like non-metal marking and heat-sensitive applications, mechanical engraving offers deep, tactile marks for rugged applications. By considering the unique needs of their production processes, manufacturers can determine the optimal marking technology for their specific goals and constraints.

Factors to Consider When Choosing a Marking Solution

When selecting the most appropriate marking solution for your business, it is important to evaluate a range of factors to ensure optimal performance and return on investment. Fiber laser marking machines offer numerous advantages, but it is crucial to consider specific criteria before making a decision.

Material Type and Compatibility

The type of material you intend to mark plays a significant role in determining the best marking solution. Fiber laser marking machines excel at marking metals, including stainless steel, aluminum, brass, and titanium, as well as select plastics and ceramics. However, they may not perform well on transparent materials like untreated glass or organic materials like wood. Carefully assess the compatibility of the laser system with your materials to avoid any potential limitations. If your application involves marking non-metals, such as wood, fabric, or acrylic, alternative technologies, such as CO2 or UV lasers, may be more suitable.

Desired Marking Quality

The quality of the markings required is another key consideration. Fiber laser marking machines are known for their high precision, excellent beam quality, and ability to create detailed, intricate, and high-resolution marks with smooth edges. If your application demands fine details, such as micro-markings or complex patterns, fiber lasers are an excellent choice. Conversely, if deep engraving or tactile markings are necessary, other technologies, like mechanical engraving, may be more suitable.

Production Volume and Speed

Consider the volume of products you need to mark and the speed at which they must be processed. Fiber laser marking machines operate at high speeds, making them well-suited for high-volume production environments where efficiency is crucial. For lower-volume applications, alternative solutions may offer sufficient performance at a lower cost. Evaluate your production needs and choose a system that aligns with your desired throughput and productivity levels.

Budget and Cost Considerations

The initial investment, operating costs, and potential return on investment (ROI) must all be carefully weighed when choosing a marking solution. Fiber laser marking machines typically have a higher upfront cost compared to other technologies, but their long-term operational savings, low maintenance requirements, and lack of consumables often justify the expense. Consider your budget constraints, expected production volume, and potential cost savings over time when making your decision.

Technical Resources

Operating and maintaining a fiber laser marking machine requires technical expertise. Ensure that your team has the necessary skills or can be trained to set up, operate, and maintain the system. If skilled operators are not readily available, you may need to factor in additional training costs or consider simpler technologies that are easier to manage.

Software and Integration

Modern fiber laser marking machines often come with advanced software that offers flexibility and control over the marking process. Consider the software’s user interface, capabilities, and compatibility with your existing production systems. The ability to integrate seamlessly into automated production lines, customize markings, and use real-time data can enhance your production efficiency. Evaluate whether the software meets your current and future needs.

Regulatory and Safety Compliance

Marking applications often need to comply with industry standards and regulations, such as traceability, anti-counterfeiting, or product labeling requirements. Ensure that the chosen marking solution meets these regulatory needs. Additionally, consider the safety features of the machine, including protective enclosures, safety interlocks, and required operator training, to maintain a safe working environment and comply with occupational safety standards.

After-Sales Support and Training

Reliable after-sales support and training are crucial for maximizing the performance and longevity of your marking solution. Choose a supplier that offers comprehensive customer support, including technical assistance, maintenance services, and operator training programs. This ensures that you can quickly resolve any issues that arise and keep your production running smoothly.

Selecting the right marking solution involves a careful assessment of various factors, including material compatibility, desired marking quality, production requirements, budget considerations, and the availability of technical resources. By thoroughly evaluating these criteria and aligning them with your business needs, you can make a well-informed decision that maximizes productivity, efficiency, and ROI. Fiber laser marking machines offer exceptional versatility, speed, and precision, making them an attractive option for many applications—but it is essential to ensure they meet your unique requirements before committing.

Summary

Fiber laser marking machines offer a powerful combination of precision, speed, versatility, and durability, making them an indispensable tool for a wide range of industries, including automotive, electronics, aerospace, and medical devices. Their high-quality and permanent markings, low maintenance requirements, energy efficiency, and adaptability to various materials provide substantial value to manufacturers seeking reliable and efficient marking solutions. However, it is important to consider their limitations, such as the high initial investment, material compatibility constraints, and the need for skilled operation and safety measures. While fiber lasers excel at producing detailed, consistent, and durable marks with minimal environmental impact, they may not be the ideal choice for every application. By weighing the advantages and disadvantages and considering factors such as budget, production volume, and material compatibility, businesses can determine if fiber laser marking is the optimal solution to meet their specific needs and drive their production goals forward.

Get Laser Marking Solutions

Choosing the right laser marking solution for your business requires a deep understanding of your production needs, material compatibility, and desired marking outcomes. At AccTek Laser, we specialize in delivering high-performance fiber laser marking machines tailored to your unique applications. Our solutions are designed to provide unparalleled precision, speed, and long-lasting marks on a wide range of materials, including metals, plastics, and ceramics. With our industry-leading expertise, we help you achieve consistent, high-quality results while minimizing operational costs through low-maintenance and energy-efficient systems.

AccTek Laser offers comprehensive support, from pre-sales consultations to after-sales services, ensuring you maximize the potential of your investment. Whether you require stand-alone systems or integrated production line solutions, our team works closely with you to customize machines to your exact specifications. Experience the advantages of cutting-edge laser technology and elevate your marking processes with AccTek Laser’s proven solutions. Contact us today for more information.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions