What Are The Advantages And Disadvantages of Using a CO2 Laser Cutting Machine?

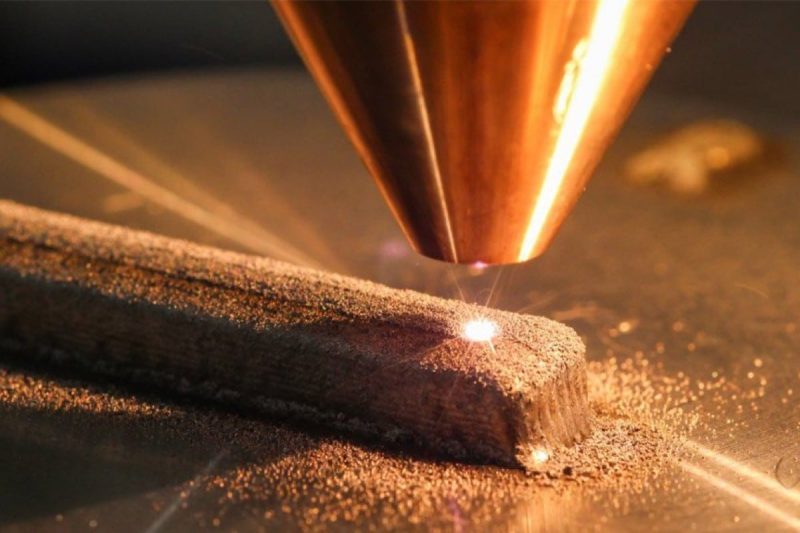

With the continuous advancement of manufacturing technology, laser cutting technology has become an indispensable part of modern industry. As a main application of laser cutting technology, CO2 laser cutting machine has been widely used in many fields. However, there are still some people who do not understand CO2 laser-cutting machines. This article will analyze the advantages and disadvantages of CO2 laser cutting machines to help readers better understand the characteristics of this cutting technology and its applicability in different application scenarios.

Table of Contents

What are the advantages of using a CO2 laser cutting machine?

There are several advantages to using CO2 laser-cutting machines that make them popular in a variety of applications. Here are some of the main advantages of CO2 laser-cutting machines:

High-precision cutting

CO2 laser cutting machines are known for their excellent precision. The laser beam can be controlled very precisely, usually between 0.1 and 0.5. This allows tiny cuts and engravings to be made on the workpiece without damaging the surrounding material. This means it can achieve complex geometries and subtle patterns, making it ideal for applications requiring fine processing, such as electronic component manufacturing and jewelry processing.

High speed cutting

CO2 laser cutting machines can complete a large amount of cutting work in a short time, far exceeding traditional cutting methods. The laser beam moves at extremely high speeds and can cut complex patterns or shapes in seconds. This makes it very useful in high-volume production, such as automotive manufacturing and sheet metal processing, to improve production efficiency.

Contactless cutting

Laser cutting is a non-contact processing method that does not require physical contact with the workpiece surface. This means that the CO2 laser cutting machine does not introduce any mechanical stress or deformation, nor does it damage the surface of the material. This is important for applications where material finish and surface quality need to be maintained. For example, CO2 laser cutters are used in microelectronics manufacturing to cut very fragile wafers or circuit boards without causing any damage to them.

Multi-material adaptability

CO2 laser cutting machines have excellent multi-material cutting capabilities and can handle many different types of materials, including metal, plastic, wood, paper, ceramics, etc. From metal processing to paper manufacturing, from woodworking to leather crafts, CO2 laser cutting machines can cut different materials as needed without changing knives or tool tables, which greatly improves work efficiency.

Automation and Programmed Control

Modern CO2 laser cutting machines are usually equipped with advanced automation and programming control systems. Operators can use computer-aided design software to create cutting paths and patterns, and then transmit these instructions to the cutting machine, enabling a highly automated production process. This automated control also enables laser cutters to handle large-scale production without the need for extensive human involvement. This reduces labor costs and reduces human error in production.

Low waste generation

CO2 laser cutting machines typically produce less scrap than traditional mechanical cutting methods. This is because laser cutting is a non-contact process that requires no saw blades or knives, thus reducing material waste. This is important for an environmentally friendly production process and also helps reduce raw material costs.

Flexibility

Laser cutting machines can be programmed and adjusted to suit a variety of materials and cutting requirements. This flexibility makes it useful in custom production and rapid prototyping.

What are the disadvantages of using CO2 laser cutting machine?

CO2 laser cutting machine offers many advantages, such as precision and versatility, but it also has some disadvantages and limitations. The following is a detailed introduction to the disadvantages of using CO2 laser cutting machines:

High Initial Cost

One of the most significant disadvantages of CO2 laser cutting machines is their higher initial cost. A CO2 laser system can be very expensive to purchase and set up, making it less accessible to small businesses and hobbyists.

Maintenance Requirements

CO2 laser generators have complex components, including mirrors, lenses, and gas tubes, which require regular maintenance and cleaning. Dust and debris can accumulate on these components, reducing machine performance and requiring frequent repairs.

operating Costs

In addition to the initial investment, CO2 laser-cutting machines have ongoing operating costs. These include the cost of electricity to power the laser, replacement of consumables (such as laser tubes), and maintenance costs. A cooling system is also required to dissipate the heat generated during the cutting process.

Limited Material Compatibility

While CO2 laser cutting machines are versatile, they may not be suitable for all materials. For example, metals often require higher-power fiber laser generators or other specialized laser generators for high-speed cutting. Additionally, some materials may emit harmful fumes when cut, requiring proper ventilation and exhaust systems.

Material Thickness Limitation

CO2 laser generators are less efficient at cutting thick materials than some other types of lasers. While it can cut a variety of thicknesses, it may struggle to cut materials above a certain thickness, resulting in slower cutting speeds and reduced quality.

Edge Quality

While CO2 laser cutting machines produce relatively clean cuts, the edges may have a slight taper or roughness, especially in thicker materials. Some applications may require post-processing such as sanding or polishing.

Reflective Material

CO2 laser cutting machines have difficulty processing highly reflective materials such as metal. The laser beam may reflect off surfaces, potentially damaging the machine or causing inconsistent cuts. Cutting reflective materials may require special coatings or techniques.

Security Question

CO2 laser generators emit invisible infrared radiation that can be harmful to the eyes and skin. Adequate safety precautions, including protective eyewear and housing systems, must be taken to prevent accidents.

Dimensions and Weight

CO2 laser cutting machines can be very large and heavy, which limits their mobility and mounting options. Setting up a CO2 laser system in a small workspace or moving it between locations can be challenging.

Operational Complexity

Operating a CO2 laser cutting machine can be complicated, especially for beginners. Proper training and experience are necessary to optimize cutting parameters and achieve desired results.

All in all, CO2 laser cutting machines are powerful tools with numerous advantages, but they do have some disadvantages, including high cost, maintenance requirements, material compatibility and thickness limitations, and safety concerns. Your specific needs and limitations must be carefully evaluated before investing in and operating a CO2 laser cutting system.

What areas can the use of a CO2 laser cutting machine be applied to?

The CO2 laser cutting machine has been widely used in many different fields. Its high -precision, high efficiency, and multi-material processing capabilities make it a multifunctional processing tool. The following are some major areas applied by CO2 laser cutting machines:

Manufacturing

The CO2 laser cutting machine is widely used and diversified in the manufacturing industry. First of all, the CO2 laser cutting machine is widely used in the field of metal processing. It can be used for different types of metals of cutting, carving, and drilling, including steel, aluminum alloy, and stainless steel. This plays a key role in automotive manufacturing, aerospace, ship construction, and metal processing industries. In addition, the CO2 laser cutting machine also plays an important role in the application of non-metallic materials, such as plastic, wood, paper, and ceramic cutting and carving. Specifically, it is reflected in the packaging industry, furniture manufacturing, art production, and electronic devices. Its high -precision, high efficiency, and multi-material applicability make it an important tool for modern manufacturing.

Medical field

The CO2 laser cutting machine is widely used in the medical field, and its high precision and no-contact properties make it a precious tool in medical equipment manufacturing and medical treatment. First of all, CO2 laser cutting machines can be used to make high-precision medical equipment components, such as implants and surgical tools. It can accurately cut metal, plastic, and bio-mag therapy materials to ensure the quality and performance of medical equipment. In addition, CO2 laser cutting is also used to manufacture minimally invasive surgical equipment, which can reduce surgical trauma and improve surgical effects.

Art and Design

First, the CO2 laser cutting machine can achieve amazing details and accuracy. Artists can engrave and cut laser beams on wood, plastic, leather, and other materials to create complex textures, shapes, and patterns. Secondly, the speed and efficiency of laser-cutting machines provide more creative freedom for artists. They can turn their ideas into practical works faster, save time and energy, and make the creative process smoother. In addition, laser cutting machines also make batch production art possible. From customized furniture to decorations, it can be easily implemented through laser cutting.

Other industries

The CO2 laser cutting machine is also an indispensable tool in other industries. It’s high-precision and multi-material cutting ability make it an ideal tool for interior decoration. In decoration manufacturing, laser cutting can be used to create exquisite metals, wood, or acrylic carvings, such as wall decoration, chandeliers, furniture, and decorative boards. In the field of construction, the CO2 laser cutting machine can be used to customize the appearance and components of the building. It can cut complex metal panels, railings, fences, and staircase armrests to give the building artistic and personalized characteristics.

Summarize

In short, although the CO2 laser cutting machine has significant advantages in many applications, there are also some disadvantages and restrictions. It is necessary to evaluate and consider based on specific application requirements and material selection. However, the advantages of CO2 laser cutting machine are far greater than its shortcomings. It is worth buying a qualified CO2 laser-cutting machine to develop your business. If you need to buy a CO2 laser cutting machine and related accessories, please contact AccTek Laser, and we will determine the model, power, size, and other configuration of the CO2 laser machine according to your production needs and processing materials.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions