Understanding Fiber Laser Cutting Machines

What is Fiber Laser Cutting?

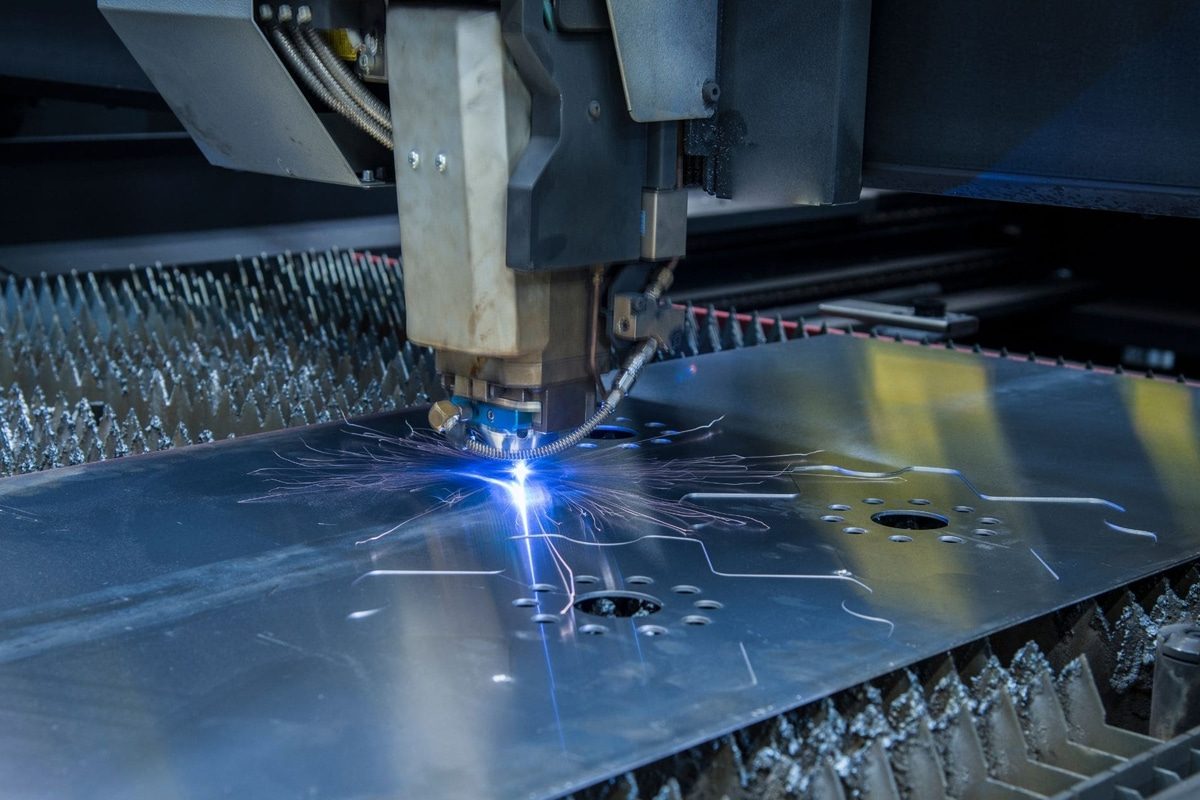

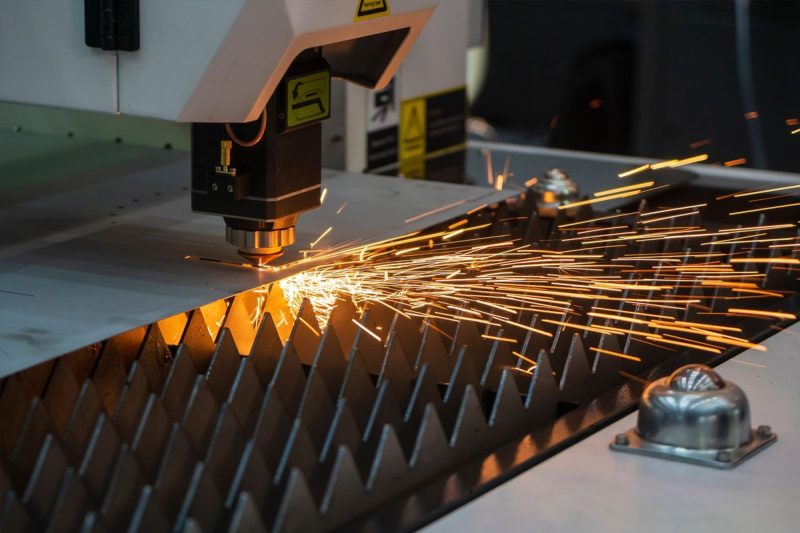

How Do Fiber Laser Cutting Machines Work?

The operation of fiber laser cutting machines involves several steps:

- Laser Beam Generation: The laser source contains numerous diodes that generate light. This light is transmitted through flexible optical fibers, where it is amplified into a powerful beam.

- Focusing and Cutting: The laser beam is directed through focusing optics to a precise point on the material surface. The focused beam creates intense heat, which melts or vaporizes the material along the cutting path.

- Computer Numerical Control (CNC) System: CNC technology guides the laser beam with incredible accuracy, following pre-programmed paths to cut intricate shapes and designs. This system ensures precise and repeatable results.

- Assisting Gas: In many cases, an assisting gas—such as nitrogen, oxygen, or air—is used to blow away molten material, prevent oxidation, and improve cutting quality.

- Cooling System: Fiber laser machines rely on cooling systems to maintain optimal operating temperatures, ensuring continuous operation without performance loss.

Advantages of Fiber Laser Cutting Machines

High Precision and Accuracy

Fiber laser cutting machines are known for their exceptional accuracy, making them ideal for intricate designs and complex parts. The concentrated laser beam creates a narrow kerf (cutting width), minimizing material waste and enabling tight tolerances. The precision also reduces the need for secondary processing, such as grinding or polishing, saving time and resources.

- Minimal Heat-Affected Zone (HAZ): The focused beam generates less heat, reducing distortion in delicate materials.

- Consistent Quality: With CNC-controlled operation, fiber lasers can replicate precise cuts across large production batches.

Speed and Efficiency

The high cutting speed of fiber laser machines ensures faster processing times, which increases productivity and enables manufacturers to meet tight deadlines. Compared to traditional cutting methods, fiber lasers complete tasks more quickly while maintaining superior quality.

- High-Speed Production: Suitable for high-volume production environments where time is critical.

- Reduced Downtime: Fiber lasers warm up quickly and are ready to operate, minimizing waiting periods.

Versatility

Fiber laser cutting machines can handle a wide variety of materials and thicknesses, making them a versatile tool for multiple industries. They are particularly effective for metals such as steel, aluminum, brass, and copper. Additionally, fiber lasers excel in cutting reflective materials, which are challenging for other laser types.

- Material Flexibility: From thin foils to thick metal sheets, fiber lasers can adjust to different thicknesses with ease.

- Complex Shapes and Patterns: These machines can produce intricate designs for industries like jewelry, signage, and aerospace.

Low Maintenance Costs

Fiber laser cutting machines are built with fewer moving parts, reducing the chances of mechanical failure. Their solid-state construction ensures high durability, leading to fewer breakdowns and lower maintenance costs over time.

- Long Equipment Lifespan: Fiber lasers have a longer operational life compared to other laser systems.

- Minimal Consumables: With fewer consumable parts, such as mirrors and lenses, the operational costs are lower.

Energy Efficiency

Fiber lasers are more energy-efficient than other laser types, such as CO2 lasers, providing high output with less power consumption. This efficiency not only reduces operational costs but also makes fiber laser machines more environmentally friendly.

- Better Energy Conversion: Fiber lasers convert electrical energy into laser light more effectively, improving overall system performance.

- Reduced Carbon Footprint: Lower energy consumption supports sustainable manufacturing practices.

Cost-Effectiveness

Although the initial investment for a fiber laser cutting machine may be higher, the long-term cost savings make it a highly cost-effective choice. The combination of low maintenance, reduced energy consumption, and faster production leads to significant savings over time.

- Higher ROI (Return on Investment): Faster processing and lower operational costs result in a quicker payback period.

- Less Waste: Precision cutting reduces material waste, further contributing to cost savings.

Materials That Fiber Laser Cutting Machines Can Cut

Carbon Steel (Mild Steel)

- Properties: Strong, durable, and widely used in construction and manufacturing.

- Cutting Capability: Fiber lasers cut carbon steel efficiently, handling both thin sheets and thick plates up to 25 mm or more depending on the machine’s power.

- Applications: Structural components, automotive parts, machinery, and industrial equipment.

Stainless Steel

- Properties: Corrosion-resistant with excellent strength and aesthetics.

- Cutting Capability: Fiber lasers create clean, precise edges on stainless steel, essential for products requiring high durability and smooth finishes.

- Applications: Kitchen appliances, medical instruments, food processing equipment, and architectural elements.

Aluminum and Aluminum Alloys

- Properties: Lightweight, strong, and highly reflective.

- Cutting Capability: Fiber lasers are highly effective in cutting aluminum and its alloys, achieving fast, precise cuts without the beam reflection issues faced by other laser types. Thicknesses up to 15 mm or more can be processed efficiently.

- Applications: Aerospace components, automotive parts, packaging materials, and electronics.

Copper

- Properties: Highly conductive and reflective, with excellent thermal properties.

- Cutting Capability: Fiber lasers are capable of cutting copper precisely, which is often challenging for traditional lasers. Advanced configurations prevent damage from reflected beams.

- Applications: Electrical wiring, plumbing fittings, and heat exchangers.

Brass

- Properties: An alloy of copper and zinc, with good corrosion resistance and a bright finish.

- Cutting Capability: Fiber lasers cut brass with smooth edges and minimal material loss, making it ideal for aesthetic applications.

- Applications: Musical instruments, decorative fittings, valves, and precision components.

Titanium and Titanium Alloys

- Properties: Lightweight, corrosion-resistant, with a high strength-to-weight ratio.

- Cutting Capability: Fiber lasers handle titanium and its alloys with ease, maintaining material properties essential for high-performance applications.

- Applications: Aerospace parts, medical implants, and military equipment.

Galvanized Steel

- Properties: Steel coated with a layer of zinc to protect against corrosion.

- Cutting Capability: Fiber lasers can cut galvanized steel effectively without compromising the zinc coating. This ensures the material retains its corrosion-resistant properties.

- Applications: Automotive bodies, roofing sheets, and outdoor structures.

Nickel Alloys

- Properties: Known for their resistance to extreme temperatures and corrosion.

- Cutting Capability: Fiber lasers are capable of cutting nickel-based superalloys with precision, ensuring high performance for components used in harsh environments.

- Applications: Turbine blades, marine engineering components, and chemical processing equipment.

Gold

- Properties: Soft, malleable, and highly conductive, with a bright yellow finish.

- Cutting Capability: Fiber lasers enable intricate cutting and engraving of gold with minimal material waste.

- Applications: Jewelry, decorative pieces, and electronic connectors.

Silver

- Properties: The most conductive metal, with a shiny, reflective surface.

- Cutting Capability: Fiber lasers effectively cut silver despite its high reflectivity, making it ideal for precision designs.

- Applications: Jewelry, mirrors, electrical components, and fine silverware.

Platinum

- Properties: Dense, corrosion-resistant, and valuable, with a silvery-white appearance.

- Cutting Capability: Fiber lasers cut platinum efficiently, producing high-quality finishes for luxury applications.

- Applications: High-end jewelry, laboratory instruments, and catalytic converters.

Applications of Fiber Laser Cutting Machines

Metal Fabrication Industry

The metal fabrication industry relies heavily on fiber laser cutting machines for their ability to process a wide range of metals with precision and efficiency.

- Sheet Metal Cutting: Fiber lasers are ideal for cutting thin to medium-thickness sheets of steel, aluminum, and other metals. They provide precise cuts with minimal waste, allowing for the production of components with perfect dimensions and smooth edges.

- Metal Profiles and Tubes: Fiber lasers are capable of cutting intricate shapes and patterns on metal profiles and tubes, which is crucial for industries like construction and automotive. They can handle a variety of shapes, including round, square, and rectangular tubes.

- Precision Parts: For high-precision components used in industries such as aerospace and medical devices, fiber lasers deliver exceptional accuracy and consistency. This is essential when tight tolerances are required to ensure proper fit and function.

Automotive Industry

Fiber laser cutting technology has become integral in automotive manufacturing, both for prototyping and mass production.

- Car Body Parts: Fiber lasers cut car body panels and structural components with high precision, allowing for complex designs that improve vehicle aerodynamics and aesthetics. Lightweight materials like aluminum and advanced high-strength steel can be cut easily.

- Engine Components: Fiber lasers cut intricate engine parts such as gaskets, brackets, and mounting plates, ensuring precision for performance-critical components.

- Exhaust Systems: Fiber laser cutting is used to manufacture exhaust systems from heat-resistant materials such as stainless steel, contributing to better durability and performance in harsh conditions.

Aerospace Industry

In the aerospace industry, where precision and material performance are paramount, fiber laser cutting machines play a critical role.

- Aircraft Components: Cutting lightweight metals such as titanium and aluminum with fiber lasers reduces aircraft weight, improving fuel efficiency and performance. These components are vital for the structure and function of modern aircraft.

- Turbine Blades: Fiber lasers cut turbine blades used in aircraft engines and power generation systems. These blades require precise cooling channels and complex geometries, which fiber lasers can achieve.

- Structural Parts: Fiber laser cutting machines are also used to fabricate various structural parts in the aerospace industry, where consistency and material integrity are critical.

Electronics and Electrical Industry

As electronic devices become smaller and more complex, fiber lasers have become an essential tool for precision cutting in this sector.

- Circuit Boards: Fiber laser cutting is used for creating printed circuit boards (PCBs) with high precision, ensuring clean cuts that don’t damage sensitive components.

- Enclosures: Metal enclosures for electronic devices, such as casings for computers and other gadgets, are cut using fiber lasers to ensure proper fit and protection for internal components.

- Electrical Components: Fiber lasers are used to manufacture various electrical components such as connectors and terminals, ensuring they meet the strict standards required for electrical conductivity and durability.

Medical Device Manufacturing

Fiber laser cutting machines are vital for producing high-precision medical devices, where accuracy and cleanliness are crucial.

- Surgical Instruments: Precision is critical in the production of surgical tools. Fiber lasers cut surgical instruments from materials like stainless steel and titanium, providing smooth, clean edges that reduce the risk of contamination.

- Medical Implants: Fiber lasers can create custom-designed implants such as bone plates and dental implants with intricate geometries tailored to individual patients.

- Dental Devices: Fiber lasers are also used to produce dental appliances such as crowns, bridges, and orthodontic devices, ensuring a perfect fit and high-quality finish.

Jewelry Industry

Fiber laser cutting technology offers jewelers the ability to create intricate and customized designs with high precision.

- Precious Metals Cutting: Fiber lasers are capable of cutting precious metals like gold, silver, and platinum with minimal material waste, ensuring that valuable materials are used efficiently.

- Intricate Designs: Jewelers use fiber lasers to create detailed patterns and engravings that would be difficult or impossible with traditional methods.

- Custom Jewelry: Fiber lasers allow for personalization and custom designs, enabling jewelers to meet the specific requests of clients with high precision.

Advertising and Signage

In the advertising industry, the visual appeal and durability of signage are crucial, making fiber lasers an excellent choice for cutting and engraving.

- Metal Signs: Fiber lasers are used to cut metal signs with precision, allowing for crisp edges and high-quality finishes that withstand the elements.

- Decorative Elements: Custom designs and artistic elements can be easily incorporated into metal signs and advertising materials, giving businesses the ability to create unique branding.

- Artistic Creations: Artists and designers also use fiber lasers to create metal sculptures and decorative pieces, leveraging the precision and flexibility of the technology.

Architectural and Construction Industry

Fiber laser cutting machines contribute to innovative architectural designs and structural elements in construction.

- Structural Components: Laser-cut structural components such as beams and supports provide precision and strength, ensuring the structural integrity of buildings and infrastructure.

- Facade Elements: Fiber lasers allow for the creation of decorative metal facades and architectural features, giving designers the freedom to experiment with complex patterns and shapes.

- Decorative Metalwork: Fiber lasers are also used to cut and engrave decorative elements such as railings, gates, and interior design features, offering both functionality and aesthetics.

Agricultural Machinery

Agriculture relies on durable, reliable machinery, and fiber laser-cutting machines play a role in producing these essential components.

- Equipment Parts: Fiber lasers cut parts for agricultural machinery such as tractors and harvesters, ensuring they are strong enough to handle the tough conditions of farming.

- Machinery Components: Various other components, such as gears, blades, and brackets, are cut using fiber lasers to ensure precision and durability in agricultural equipment.

Energy Sector

Fiber laser cutting machines are used in both traditional and renewable energy sectors for manufacturing key components.

- Oil and Gas Equipment: Fiber lasers are employed to cut components for drilling rigs, pipelines, and valves, ensuring that these critical parts are durable and able to withstand harsh environments.

- Renewable Energy Components: In the renewable energy industry, fiber lasers are used to cut parts for wind turbines, solar panels, and other equipment that contributes to clean energy production.

Shipbuilding Industry

In shipbuilding, the ability to cut large metal components with precision and efficiency is crucial.

- Hull Components: Fiber lasers cut large metal sheets for ship hulls, ensuring that components fit together accurately, and reducing the time required for assembly and welding.

- Structural Parts: Fiber lasers are also used to fabricate structural parts that are essential for the integrity and performance of ships, particularly in harsh marine environments.

Summary

Get Laser Cutting Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.