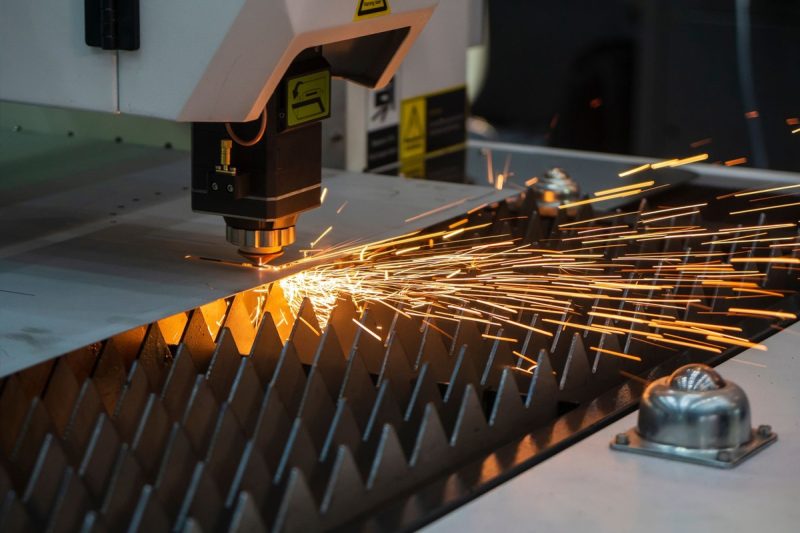

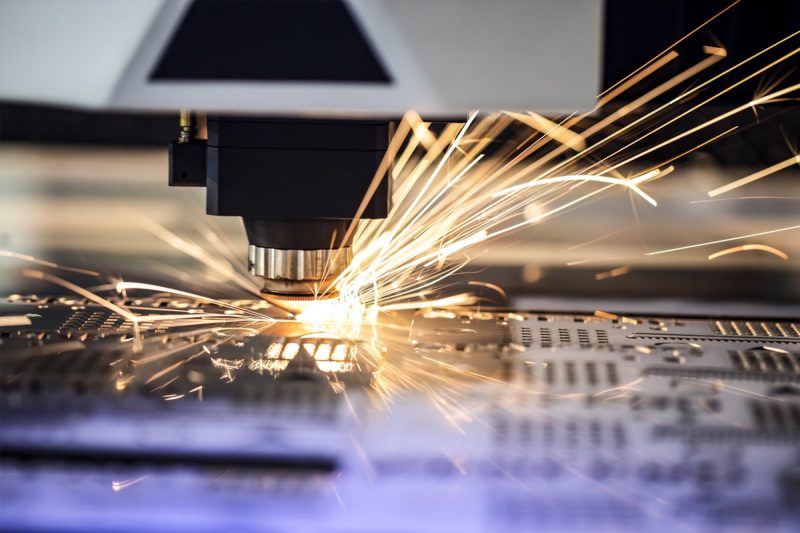

Overview of Laser Cutting Technology

Brief History

How Laser Cutting Works

Laser cutting involves using a high-powered, focused laser beam to melt, burn, or vaporize material in a precise pattern. The process typically includes:

- Laser Generation: The laser source (CO2, fiber, or Nd:YAG) generates a high-energy beam.

- Beam Delivery: The beam is directed to the cutting head using mirrors or fiber-optic cables.

- Focusing: Lenses or mirrors focus the beam into a fine point, increasing its intensity.

- Material Interaction: The focused laser beam interacts with the material, cutting through it by melting or vaporizing, often assisted by a gas like oxygen, nitrogen, or air.

- Motion Control: Computer-controlled systems guide the laser head or material to create intricate shapes and designs.

Advantages of Laser Cutting

Laser cutting stands out for its numerous benefits, making it a preferred choice for manufacturers worldwide:

- Precision and Accuracy: Laser cutting achieves tolerances as tight as ±0.1mm, making it ideal for intricate designs.

- Versatility: Capable of cutting a wide range of materials, including metals, plastics, wood, and composites.

- High Efficiency: Fast processing speeds and reduced material waste increase production efficiency.

- Clean Edges: The focused heat minimizes burrs and the need for post-processing.

- Non-Contact Process: No mechanical stress is applied to the material, preserving its integrity.

- Automation Friendly: Easily integrated with CNC systems for repeatable and consistent results.

- Minimal Maintenance: Fiber laser generators, in particular, offer long operational lifespans with low maintenance requirements.

Classification of Laser Cutting Machines

Based on Laser Source

Fiber Laser Cutting Machines

Working Principles:

- Fiber lasers use optical fibers doped with rare-earth elements, such as ytterbium, to amplify light.

- The laser beam is generated and delivered directly through fiber-optic cables, eliminating the need for complex mirrors and lenses.

- Operating at a wavelength of approximately 1.06 micrometers, the concentrated laser beam achieves a high power density ideal for metal cutting.

Applications:

- Metal Processing: Stainless steel, carbon steel, aluminum, brass, copper, and titanium.

- Precision Industries: Aerospace, medical devices, electronics, and jewelry.

- High-Speed Production: Automotive and heavy machinery manufacturing.

Advantages:

- High Cutting Speeds: Faster processing than CO2 lasers, especially for metals.

- Energy Efficiency: Consumes significantly less power, lowering operational costs.

- Low Maintenance: Few moving parts and no mirror alignment required.

- Compact Design: Smaller footprint compared to CO2 systems.

- Durability: Longer operational lifespan, often exceeding 100,000 hours.

Disadvantages:

- Higher Initial Cost: Substantial upfront investment.

- Limited Non-Metal Applications: Ineffective for cutting materials like wood, glass, and acrylic.

- Reflective Material Challenges: Cutting reflective metals like copper requires specialized configurations.

CO2 Laser Cutting Machines

Working Principles:

- CO2 lasers generate a laser beam by electrically exciting a gas mixture of carbon dioxide, nitrogen, and helium.

- The laser emits infrared light at a wavelength of 10.6 micrometers, which is directed through a system of mirrors and lenses to the cutting surface.

- The intense heat generated melts, burns, or vaporizes the material to create clean, precise cuts.

Advantages:

- Wide Range of Materials: Excels in cutting and engraving non-metals.

- Smooth and Clean Edges: Minimal post-processing required.

- Proven Technology: Reliable, with extensive industry support and resources.

- Lower Cost: Initial investment is lower than other advanced laser systems.

Disadvantages:

- Limited Metal Cutting: Inefficient for cutting thick or reflective metals.

- Maintenance-Intensive: Requires regular cleaning, mirror alignment, and replacement of consumables.

- Energy-Intensive: Less efficient than newer technologies like fiber lasers.

- Slower Cutting Speed: Cannot match the high-speed capabilities of fiber lasers.

Nd:YAG Laser Cutting Machines

Working Principles:

- Nd:YAG lasers use a crystal rod doped with neodymium ions as the gain medium.

- Light amplification occurs within the crystal, generating a laser beam with a wavelength of 1.064 micrometers.

- The beam can be emitted in either continuous-wave or pulsed modes, offering flexibility for various applications.

Applications:

- High-Precision Cutting: Electronics manufacturing, medical device production, and jewelry.

- Metal Processing: Cutting and welding of steel, aluminum, and other metals.

- Micromachining: Creating small, intricate components.

Advantages:

- High Peak Power: Suitable for detailed work and thick material cutting.

- Versatility: Effective for cutting, welding, and drilling applications.

- Compact Design: Ideal for small-scale, high-precision production.

- Pulse Mode: Reduces heat-affected zones, preserving material properties.

Disadvantages:

- Energy Inefficiency: Consumes more energy compared to fiber lasers.

- High Maintenance Costs: Frequent replacement of flash lamps and careful cooling required.

- Limited Lifespan: Shorter operational life compared to fiber lasers.

Based on Material to Be Cut

Metal Laser Cutting Machines

Features:

- Equipped with fiber lasers for cutting metals of varying thicknesses.

- Assist gases (e.g., oxygen, nitrogen) enhance cutting speed and edge quality.

Applications:

- Thin and Thick Metals: Carbon steel, stainless steel, aluminum, brass, and titanium.

- Complex Shapes: Components for the automotive, aerospace, and construction industries.

Advantages:

- High precision with minimal material waste.

- Capable of cutting reflective and non-reflective metals.

Disadvantages:

- Higher operational and maintenance costs.

- Requires expertise in parameter setup for complex materials.

Non-Metal Laser Cutting Machines

Features:

- Adjustable cutting parameters for delicate materials.

- Excellent for heat-sensitive applications.

Applications:

- Organic Materials: Wood, acrylic, textiles, leather, and paper.

- Engraving: Artistic designs on ceramics, plastics, and glass.

Advantages:

- Clean and precise cuts with minimal damage.

- Ideal for artistic and decorative applications.

Disadvantages:

- Cannot cut metals effectively.

- Requires frequent maintenance for consistent performance.

Based on Application

Industrial Laser Cutting Machines

Applications:

- Mass production of metal parts and machinery components.

- Cutting large, complex workpieces with high accuracy.

Advantages:

- High throughput and repeatability.

- Capable of handling heavy workloads.

Disadvantages:

- High cost and large footprint.

- Requires skilled operators and advanced maintenance.

Hobbyist/Desktop Laser Cutting Machines

Applications:

- Prototyping, crafting, and engraving.

- Small-scale cutting of non-metals like wood, acrylic, and paper.

Advantages:

- Easy to use and transport.

- Cost-effective for small businesses and individuals.

Disadvantages:

- Limited power and functionality.

- Unsuitable for heavy-duty or high-volume tasks.

Based on Mode of Operation

2D Laser Cutting Machines

Operate on two axes (X and Y), suitable for cutting flat materials like sheet metal, wood, and textiles.

- Applications: Sheet metal fabrication, signage, and decorative panels.

3D Laser Cutting Machines

Multi-axis motion systems enable cutting complex geometries on three-dimensional surfaces.

- Applications: Automotive parts, formed metal sheets, and aerospace components.

5-Axis Laser Cutting Machines

Advanced machines offering flexibility to cut at various angles, producing intricate shapes.

- Applications: Turbine blades, medical implants, and high-precision aerospace parts.

Based on Functionality

Optimized for cutting flat sheets of materials like metal, acrylic, or wood.

- Applications: Panels, facades, and flat components.

Designed specifically for tubular materials, such as round, square, and rectangular pipes.

- Applications: Furniture frames, automotive pipes, and structural supports.

Combines both functionalities for cutting flat sheets and tubes, making it highly versatile.

- Applications: Mixed production tasks involving both flat and tubular materials.

Key Factors to Consider When Choosing a Laser Cutting Machine

Material Compatibility

What to Consider:

- Metal Cutting: Fiber lasers excel at cutting metals like stainless steel, aluminum, brass, and copper due to their high energy density and efficiency.

- Non-Metals: CO2 lasers are better suited for cutting non-metal materials such as wood, acrylic, textiles, and glass.

- Material Thickness: Check the maximum cutting thickness the machine can handle, as different laser sources and power levels affect the range of materials that can be processed.

- Heat Sensitivity: Ensure the machine minimizes heat-affected zones for materials that are prone to warping or damage.

Power Requirements

What to Consider:

- Material Thickness: For cutting thick metals, a high-powered fiber laser (e.g., 6kW or more) is necessary, while lower power levels (e.g., 1-2kW) are sufficient for thinner materials.

- Cutting Speed vs. Power: Higher power not only allows for thicker cuts but also increases cutting speed, making it ideal for high-volume production.

- Energy Efficiency: Consider the operational power consumption to manage energy costs. Fiber lasers are generally more energy-efficient than CO2 lasers.

Cutting Speed Requirements

What to Consider:

- Material and Thickness: Cutting speed varies depending on the material and its thickness. For instance, fiber lasers cut thin metals faster than CO2 lasers.

- Production Volume: High-speed machines are essential for businesses with large-scale production requirements.

- Trade-offs: High-speed cutting may compromise edge quality, so ensure the machine meets both speed and quality expectations.

Precision and Accuracy Requirements

What to Consider:

- Tolerance Levels: Ensure the machine can meet the required tolerances, typically ranging from ±0.1mm to ±0.05mm, depending on the application.

- Beam Quality: High beam quality leads to cleaner cuts and reduces the need for post-processing.

- Motion Systems: Machines with advanced motion systems and linear guides offer better accuracy and smoother cuts.

Maintenance and Operational Costs

What to Consider:

- Consumables: CO2 lasers require more frequent replacement of mirrors and lenses, whereas fiber lasers have fewer consumable parts.

- Energy Costs: Fiber lasers consume less power compared to CO2 lasers, reducing energy bills.

- Downtime: Look for machines with minimal maintenance requirements to reduce downtime and ensure consistent productivity.

- Cooling Systems: Check if the machine requires a water or air-cooled system, as this can affect operational costs.

Software and Control Systems

What to Consider:

- Ease of Use: Look for machines with intuitive interfaces that simplify setup and operation.

- Nesting Software: Advanced nesting software optimizes material usage, minimizing waste.

- Integration: Ensure compatibility with existing CAD/CAM systems and the ability to handle complex designs.

- Automation Features: Machines with automated loading, unloading, and monitoring features streamline workflows.

Support and Service

What to Consider:

- Manufacturer Reputation: Work with reputable manufacturers like AccTek Laser that offer high-quality machines and comprehensive support.

- Technical Support: Ensure 24/7 access to technical assistance, especially for critical production environments.

- Training and Installation: Look for manufacturers that provide operator training and machine installation services.

- Spare Parts Availability: Check for the availability of spare parts and their delivery times to minimize downtime.

Summary

Get Laser Cutting Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.