What is a laser cleaning machine?

How does the laser cleaning machine work?

What can laser cleaning machines be used for?

At present, laser cleaning machines are the most widely used in metal rust removal, so it is also called laser rust removal machines. In addition to metal rust removal, the most common applications of laser cleaners include:

- Laser paint removal. Surface stripping of iron doors or machinery in need of refurbishment.

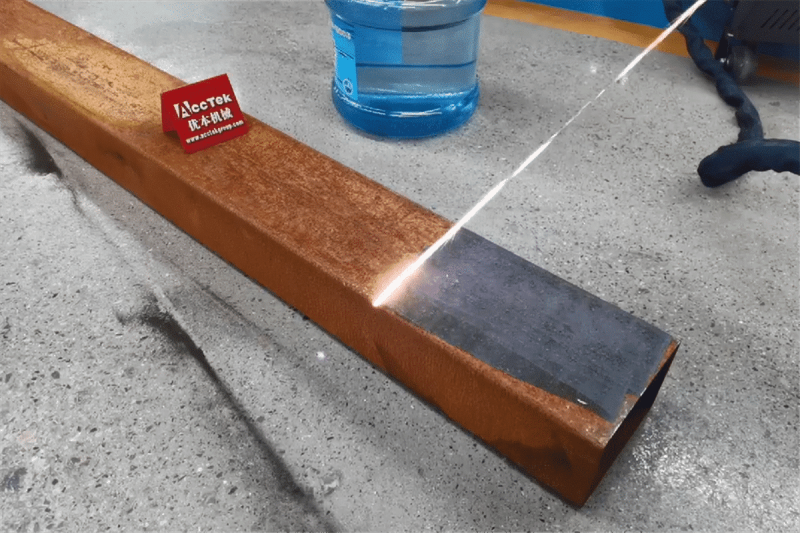

- Welding pretreatment. Use a laser cleaner to remove rust and other contaminants from the weld area to improve weld integrity.

- Weld cleaning. Remove post-weld oxides from aluminum and stainless steel to improve weld aesthetics.

- Wall graffiti cleaning. Laser cleaning machines can remove graffiti on stone surfaces and restore a clean surface.

- Laser cleaning of the surface of the material to be painted can improve paint adhesion.

- Clean the oil stains on the wood surface so that the wood products can regain a clean surface.

What are the advantages of laser cleaning machine?

- No damage to the substrate. Laser cleaning machines work by directing a powerful, high-pulse laser at a rusted, painted, or coated surface. This energy breaks down existing contaminants and effectively removes them from the substrate. Removal of the degraded layer or coating affects only a few microns. It doesn’t go on to burn off the underlying solid surface, making the laser’s action more specific.

- Safe and pollution-free. No chemical substances are used during the use of the laser cleaning machine, which is more environmentally friendly and will not cause harm to the health of the staff. The safe and pollution-free cleaning method allows laser cleaners to be used in the food and pharmaceutical industries.

- More efficient and cost-effective. Of all industrial cleaning methods, laser cleaning machines have the lowest operating costs. Lasers are many times faster than using chemicals, reducing labor costs. Since laser cleaning leaves no waste or debris behind, a significant amount of material and tooling costs are eliminated. Return on investment can often be seen in less than a year.

- Selectively and accurately peel off the cleaning layer. Unlike sandblasting, lasers are selective and can be easily focused on very small spots or stripes without affecting adjacent materials. Precise and spot cleaning is easier with a laser cleaner. Additionally, the nooks and corners of intricately designed objects can be reached more easily with laser cleaning. The final product after laser cleaning is much finer than other cleaning methods.

In what environment can the laser cleaning machine operate effectively?

To ensure the long-term and effective operation of the laser cleaning machine, the environment in which the machine is used needs to be controlled. The optical components in the laser cleaning machine have relatively high requirements on the environment. The humidity and dust in the air should not be too large, there should be no strong sources of interference and vibration, and the temperature of the working environment must be stable. The following are specific requirements for effectively operating a laser cleaning machine:

- Make sure that the AC voltage supply is normal. The power of the laser cleaning machine is different, and the voltage used is different. Under normal circumstances, laser cleaning machines below 2000W use 220V AC power; 3000W laser cleaning machines use 380V AC power. Improper connection of the power supply may cause the laser generator to malfunction and fail to work.

- Electrically safe. When using a laser cleaning machine, a ground wire is required, and a disconnection of the ground wire may cause personal injury to the operator.

- placement environment. When using a laser cleaning machine, make sure that the machine is placed flat, without vibration or impact.

- Laser cleaning machines should be used in a well-ventilated environment. In addition, be careful not to block the air inlet and outlet of the machine, and leave at least 20cm of ventilation distance between the front and back of the fuselage. Insufficient ventilation distance may cause the internal laser generator to malfunction and fail to work.

- The operating environment temperature range of the laser cleaning machine is 0-40° If the operating temperature range is exceeded, the internal laser system may alarm and not emit light. This is a protective behavior, which can effectively protect the long-term reliability of the machine. In low-temperature conditions, it needs to be warmed up to start. It is recommended that the operating environment temperature range of the laser cleaning machine is 10-30°C. Good heat dissipation will help prolong the working life of the machine.

- The operating environment humidity of the laser cleaning machine ranges from 5 to 80%, without condensation.

- Do not work outdoors in rainy weather, otherwise, it may cause a short circuit, affect the normal use of the device, and even cause safety hazards.

- Do not use the laser cleaner in a dark environment.

- When the laser cleaning machine works in a dusty environment, it must be connected with anhydrous and purified air to blow the laser head. Otherwise, the smoke and dust falling on the lens will cause damage to the lens. It is recommended to use air blowing to remove dust from the field lens and laser head after each use of the laser cleaning machine. It can also be wiped with a lens cloth to prevent dust or other contamination. When the laser cleaning head is not working, please cover the field lens with a protective cover.

- Laser cleaning machines have high requirements for the cleanliness of the environment. Please handle the laser cleaning head carefully to prevent dust or other pollution when using or moving the machine. The dust on the surface of the hand-held laser cleaning head may cause the lens to heat up and be damaged, resulting in attenuation of the output power of the machine or failure to emit light.

- It is forbidden to place flammable and explosive materials in the workplace of the laser cleaning machine, so as not to cause a fire. Do not use the machine in the presence of volatile solvents such as alcohol, steam, oil, etc.

- Do not prevent reflective materials or unnecessary metal objects in the working environment of the laser cleaning machine, so as not to cause damage to the laser generator.

- When using a laser cleaning machine, try to avoid working near large electromagnetic interference sources, such as high-power electrical appliances or distribution boxes, which will affect the operation of the machine controller.

What should be paid attention to when operating a laser cleaning machine?

Although the laser cleaning machine is easy to operate and easy to use, the operator also needs to strictly follow the instructions and precautions to operate to improve the cleaning efficiency and effect under the premise of safety. The following are safety precautions for operating a laser cleaning machine:

- Before using the laser cleaning machine, you should check it first. At this time, you should make sure that the machine is powered off.

- Laser has strong penetrating power and radiation, and it is necessary to strictly abide by the safety operation regulations when using it. The operator of the laser cleaning machine or the person working close to the machine must wear protective glasses that meet the regulations, and do not look directly at the laser beam.

- When the laser cleaning machine is powered on, it is forbidden to point the laser cleaning head in the direction of people, and it is forbidden for the laser cleaning head to irradiate the surface of highly reflective materials at will.

- Laser cleaning machines need to pay attention to dust and moisture. If you need to wipe the lens, please use a dust-free cloth and alcohol, do not use water or engine oil.

- When debugging, calibrating, or focusing the machine, please do it under low power conditions. After the commissioning is completed, increase to high power work.

- Before cleaning a new workpiece, test the part of the workpiece and check its operating status to ensure the safe operation of the machine before performing large-scale cleaning.

- The laser cleaning machine should not be disassembled at will, because it has high pressure and is easy to cause harm to the human body. When the machine breaks down, it is necessary to contact professional technicians for power-on inspection.

- The operator needs to regularly check the laser cleaning machine, including safety facilities, circuits, and chiller circulation system, to ensure its normal function.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.