What Are The Factors That Affect The Cleaning Effect of Laser Cleaning Machines?

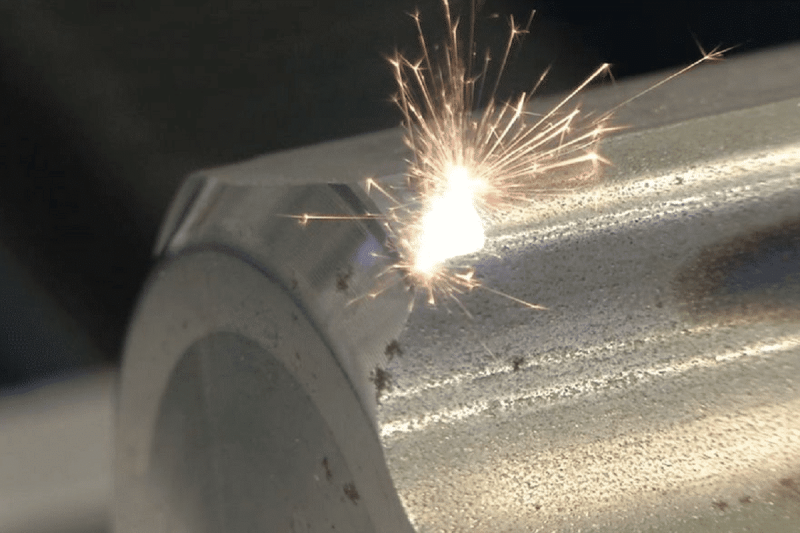

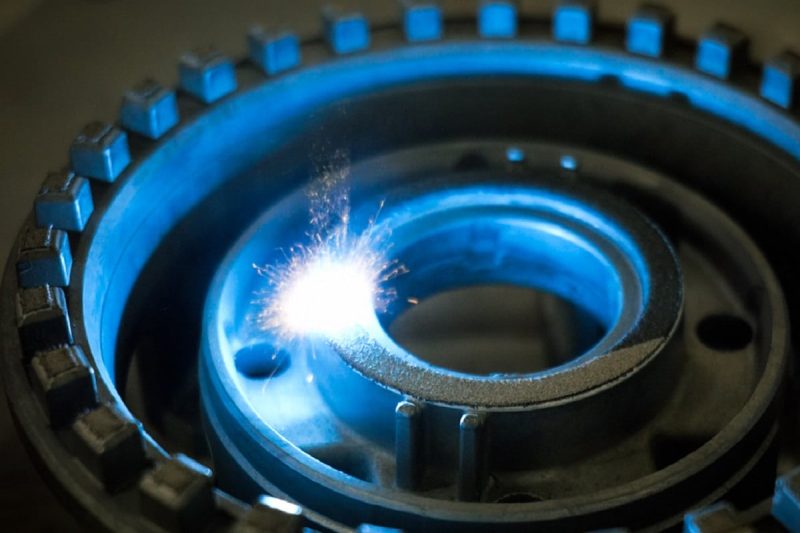

As an efficient and environmentally friendly surface cleaning method, laser cleaning machine has shown great potential in the fields of automobile manufacturing, aerospace, and electronic manufacturing in recent years. Laser cleaning uses the high energy density of the laser beam to expand, vaporize, or even peel off the dirt on the surface of the object to be cleaned, to achieve the purpose of cleaning. This method avoids the environmental problems caused by the use of chemical solvents in traditional cleaning, and at the same time reduces the loss of materials, reflecting its non-contact, high-precision, and pollution-free characteristics. However, the effect of laser cleaning is affected by many factors. This article will introduce the influence of these factors on the cleaning effect and discuss the methods to optimize the cleaning effect.

Table of Contents

How Laser Cleaning Removes Contaminants

The laser cleaning machine removes pollutants through the energy action of the laser beam, to achieve the purpose of cleaning. Before discussing the influencing factors, it is necessary to understand how laser cleaning technology removes pollutants. Here is the basic process of how a laser cleaner removes contaminants:

Absorption and transfer of energy

When the laser beam is irradiated on the surface of the pollutant, the energy of the laser will be absorbed by the pollutant. The absorbed energy causes a local temperature increase on the surface of the pollutant.

Thermal Expansion and Vaporization

When the laser beam is irradiated on the surface of the pollutant, the energy of the laser will be absorbed by the pollutant. The absorbed energy causes a local temperature increase on the surface of the pollutant.

Thermal Evaporation and Stripping

As the pollutant absorbs energy, a portion of the pollutant may undergo thermal evaporation, directly changing from a solid to a gaseous state, and evaporate from the surface. Another part of the contaminants may be gradually peeled off by the laser beam due to separation from the substrate.

Laser Beam Motion

The laser beam moves on the surface of the pollutant, and the energy is evenly transmitted to all parts of the pollutant, ensuring that the pollutant is uniformly affected by energy on the entire surface.

Cooling and solidification

When the laser beam stops working, the temperature of the surface of the pollutant will drop rapidly due to heat conduction. Part of the vaporized or evaporated contaminants refreezes on the surface, while stripped contaminants gradually cool. Repeat the above steps several times to achieve the ideal cleaning effect.

Steps to take before laser cleaning if possible

Before using laser cleaning, some specific surface preparation is usually required to ensure the best cleaning effect and avoid some potential problems. These surface preparation requirements may vary for different cleaning goals, materials, and applications. The following are some common surface preparation requirements:

Remove large particles of dirt

Before using laser cleaning, it is first necessary to ensure that large particles of dirt, dust, or foreign matter on the surface have been completely removed. These particles may hinder the action of light and affect the cleaning effect.

Removal of coating or covering

If there is a coating, paint, film, or other covering on the surface of the object being cleaned, it may need to be removed before cleaning. Lasers are generally better suited for interacting directly with surfaces rather than covering them.

Preprocessing

For some materials and contaminants, pretreatment may be necessary. For example, some metal surfaces may need to undergo degreasing, deoxidation, and other treatment steps so that the laser can better act on its surface.

Stability of cleaning material

It is crucial to ensure that the object being cleaned can withstand the energy density and thermal effects of the laser. Certain materials may be very laser sensitive and may be damaged or deformed during cleaning. Before cleaning, it is necessary to evaluate the material properties and stability of the object to be cleaned.

Control surface temperature

In some cases, the surface temperature of the object to be cleaned may affect the cleaning effect of the laser. Excessively high temperatures may cause evaporation on the surface of the object to be cleaned, affecting the cleaning quality. Therefore, it may be necessary to control the surface temperature to ensure cleaning effectiveness.

Select appropriate laser parameters

When selecting laser cleaning parameters, the characteristics, shape, and material of the object to be cleaned need to be considered. Different laser parameters may be suitable for different cleaning targets and thus need to be adjusted on a case-by-case basis.

Factors Affecting Laser Cleaning Results

Factors affecting the cleaning effect of laser cleaning machines cover multiple aspects. From laser parameters to the nature of being cleaned, they may affect the cleaning effect. Here are some main factors:

Laser parameter selection

The parameter setting of the laser cleaning machine directly affects the cleaning effect. The selection of parameters such as laser power, pulse frequency, and pulse width will affect the energy density and action time of the laser beam, thereby affecting the cleaning effect. Too high laser power may cause damage to the surface of the object to be cleaned, while too low may not be able to effectively remove dirt.

Cleaning surface properties

The material, roughness, and shape of the object to be cleaned will affect the absorption and reflection of the laser. Different materials have different absorption capabilities for laser light, and surface roughness may make it difficult to distribute laser energy evenly, thereby affecting the uniformity of cleaning.

Laser Beam Focusing

The focus of the laser beam is closely related to the cleaning effect. If the laser beam is too focused, it may cause local overheating, and if it is not focused enough, it will affect the cleaning effect. The process of focusing the laser beam requires precise optical system support.

Dirt type and adhesion degree

Different types of dirt have different absorption capabilities to laser light, so their cleaning effects will also vary. Higher levels of dirt may require higher-power lasers to remove effectively.

Environmental factors

Environmental factors such as temperature and humidity will also affect the laser cleaning effect. Excessive temperature may cause evaporation on the surface of the object to be cleaned, and excessive humidity may affect the propagation and cleaning effect of the laser in the air.

Cleaning distance and angle

The energy of the laser will gradually attenuate during the propagation process, the selection of the cleaning distance will affect the energy density of the laser, and the selection of the cleaning angle will also affect the irradiation of the laser on the dirt.

Laser Beam Stability

The stability of the laser beam has an important influence on the cleaning effect. The instability of the laser beam may lead to uneven energy distribution and affect the consistency of cleaning.

Cleaning distance and angle

Real-time monitoring and control of the cleaning process is crucial to ensure the cleaning effect. By monitoring the surface quality and residual dirt after cleaning, and timely adjusting laser parameters and cleaning strategies, the cleaning effect can be improved.

How to optimize the results of laser cleaning

Affected by various factors, the effect of laser cleaning will gradually deteriorate. Optimizing the effect of laser cleaning is the key to ensuring cleaning quality and efficiency. Here are some methods and tips to help you optimize the results of your laser cleaning:

Determining Appropriate Laser Parameters

The selection of parameters such as laser power, pulse frequency, and pulse width directly affects the cleaning effect. According to the characteristics of the object to be cleaned and the type of dirt, select the appropriate laser parameters to achieve the best cleaning effect.

Consider Surface Properties

The material, roughness, and shape of the object to be cleaned will affect the absorption and reflection of the laser. Knowing the surface properties allows you to choose the proper laser parameters and focus to ensure uniform energy delivery to all parts of the surface.

Optimizing Laser Beam Focus

Make sure the laser beam is properly focused, neither too focused nor too scattered. Reasonable focusing can ensure that the laser energy is evenly distributed on the surface of the dirt, avoiding the problem of overheating or insufficient energy.

Consider the type of dirt and the degree of adhesion

Different types of dirt may require different laser parameters and treatments. Know the type and degree of adhesion of the dirt, and adjust the laser parameters to provide the best cleaning effect.

Implement environmental controls

Environmental factors such as temperature and humidity can affect laser cleaning results. During the cleaning process, try to control the environmental conditions and make sure that the temperature and humidity are within the appropriate range.

Perform preprocessing

In some cases, the cleaned material may need to be pre-treated, such as degreasing, deoxidizing, etc. Pretreatment can improve laser cleaning results, making it more thorough and efficient.

Summarize

As an efficient and environmentally friendly cleaning method, laser cleaning technology has shown broad prospects in many fields. However, its cleaning effect is affected by many factors, including laser parameters, surface characteristics of the object to be cleaned, laser beam focus, type of dirt, environmental factors, etc. Only by comprehensively considering these factors and making appropriate adjustments and optimizations can the ideal cleaning effect be achieved.

AccTek Laser focuses on the design, production, and sales of laser cleaning machines, you can ask us about laser cleaning. Talk to us to determine your cleaning options and test our laser solutions to find out which parameter settings get the results you want.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions