Laser Power and Type

Laser Power Output

The laser power output, measured in watts (W), is a key determinant of a laser cleaning machine’s performance and cost. Higher power enables faster and deeper cleaning, suitable for removing heavy contaminants, such as rust, paint, or thick coatings. However, increased power also comes at a higher price due to the sophisticated technology and components required to maintain performance.

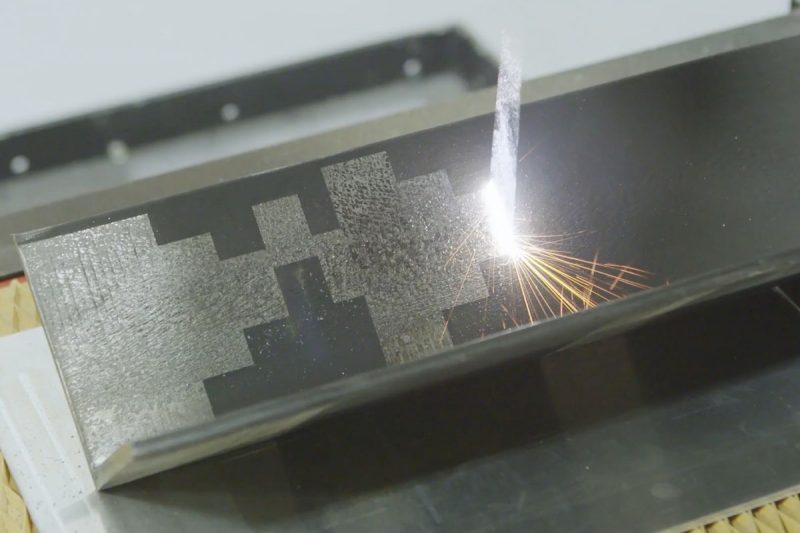

- High-Power Lasers (1500W and Above): Best suited for industrial-scale cleaning tasks, where rapid and extensive material removal is necessary. While they have a higher initial cost, these machines offer superior cleaning speed and effectiveness, making them ideal for heavy-duty applications.

- Medium-Power Lasers (500W – 1000W): These provide a balance between cleaning efficiency and cost. They can effectively handle a wide range of general-purpose cleaning tasks.

- Low-Power Lasers (100W – 500W): Suitable for delicate or precise cleaning applications where minimal material removal is necessary. These are more affordable but have limited capacity for heavier cleaning tasks.

Type of Laser Source

The type of laser source used in a cleaning machine plays a crucial role in its performance characteristics, versatility, and cost. Laser cleaning machines can be equipped with either pulse lasers or continuous wave (CW) lasers, each offering distinct advantages and trade-offs.

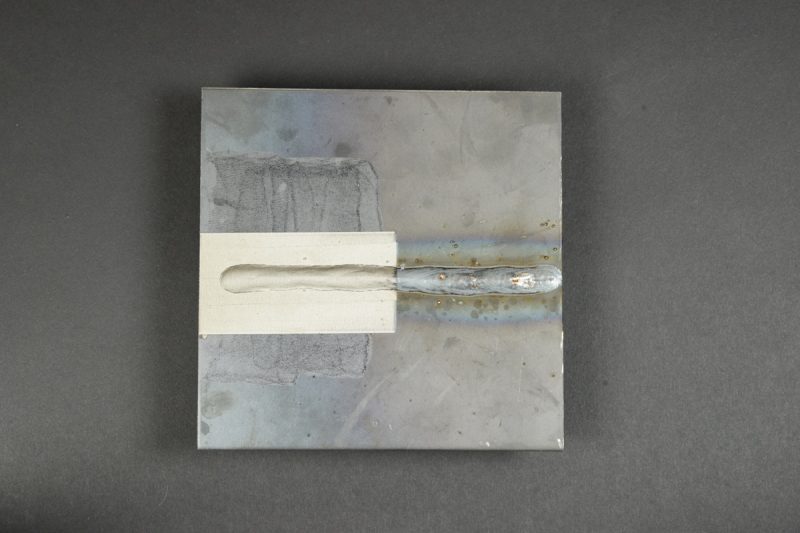

- Pulse Laser: Pulse laser cleaning machines emit high-intensity bursts of energy in short durations, allowing for precise material removal without causing excessive heat buildup on the surface. This makes them ideal for delicate substrates or applications where controlled cleaning is crucial. Pulse lasers are often used for removing coatings, and oxide layers, or for restoration projects. The precision and lower risk of damage can make pulse lasers more costly than their continuous counterparts.

- Continuous Wave (CW) Laser: Continuous wave lasers emit a constant, uninterrupted beam of energy, making them highly effective for applications requiring fast, large-area cleaning. CW lasers are often used for removing rust, thick coatings, and other industrial cleaning applications that require high speed and power. While they may not offer the same level of precision as pulse lasers, they often provide higher cleaning rates. Machines with CW lasers are generally more affordable than pulse lasers, although they may consume more energy and generate more heat during operation.

Quality and Brand of the Laser Source

The quality and brand of the laser source significantly impact the cost of a laser cleaning machine. High-quality laser sources provide consistent performance, reliability, and longevity, which can influence the initial investment and total cost of ownership.

- High-Quality Laser Sources: Leading brands such as IPG Photonics, Raycus, and Max are known for producing durable and efficient laser sources. These brands offer exceptional performance and low maintenance requirements, enhancing the overall value and productivity of the machine. Machines equipped with high-quality sources typically command a higher purchase price but deliver better performance and lower long-term operational costs.

- Lower-Quality Laser Sources: Opting for less expensive or lower-quality laser sources may reduce the initial investment. However, this often comes at the cost of inconsistent performance, higher maintenance needs, and potentially shorter service life. Over time, these factors can increase the total cost of ownership.

Technology and Features

Automation Level

The level of automation in a laser cleaning machine greatly impacts its cost and usability. Automation determines the extent to which a machine can operate independently, enhancing productivity, precision, and consistency.

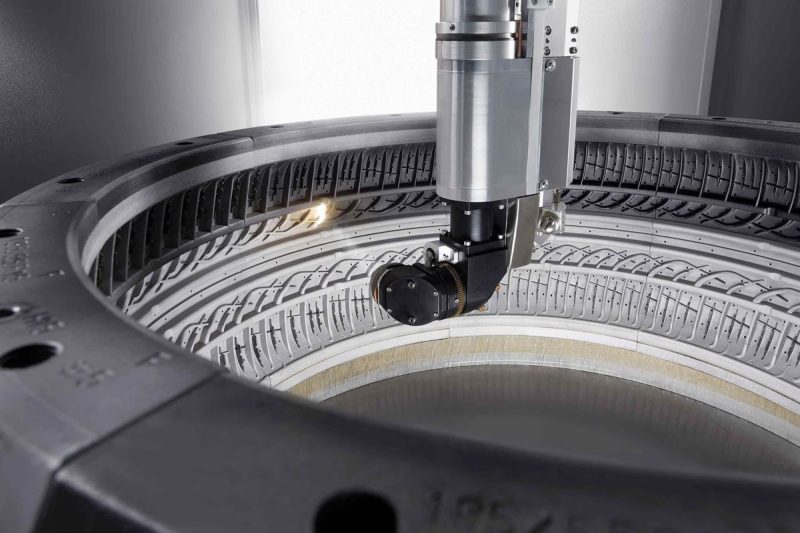

- Fully Automated Systems: These machines can be integrated into production lines and operate with minimal human intervention. They often include features such as robotic arms, programmable cleaning paths, and real-time monitoring systems. While these capabilities offer high efficiency and precision, they also increase the initial cost due to the complexity of their design and integration.

- Semi-Automated Systems: These systems offer a blend of manual and automated functionalities, providing operators with some degree of control over the cleaning process. Semi-automated machines are moderately priced and suitable for applications where flexibility is required.

- Manual Systems: Handheld laser cleaning machines require operators to guide the laser beam manually. These machines are more cost-effective but may be limited in terms of speed and consistency compared to automated solutions.

Control Systems and Software

The control system and software used in a laser cleaning machine influence its precision, ease of use, and adaptability to different tasks. Advanced control systems allow operators to fine-tune laser parameters and optimize the cleaning process for different materials and surface conditions.

- Advanced Control Systems: High-end laser cleaning machines are equipped with sophisticated control systems that allow for precise adjustment of laser intensity, beam focus, and scanning patterns. These systems often include programmable settings, user-friendly interfaces, and compatibility with other automated equipment. Machines with advanced control systems tend to be more expensive, but they offer greater versatility and precision in cleaning operations.

- Basic Control Systems: Machines with basic control systems provide essential functions but may lack advanced features such as real-time monitoring, data logging, or remote operation capabilities. These systems are more affordable but may require more manual input from operators.

Customization Options

Customization allows laser cleaning machines to be tailored to specific applications, environments, or operational needs. The extent of customization can influence the overall cost, as it often involves modifying hardware, software, or system design.

- Hardware Customization: This can include adjustable laser heads, interchangeable nozzles, or special enclosures designed for unique cleaning tasks. Custom hardware modifications often increase production costs due to specialized engineering and manufacturing.

- Software Customization: Custom software settings can optimize the machine’s performance for specific applications or materials, adding to the overall cost but enhancing operational flexibility.

- Application-Specific Configurations: Some machines are customized for particular industries or cleaning tasks, such as rust removal, paint stripping, or delicate surface restoration. These tailored solutions may come at a premium but ensure optimal performance for specific applications.

Machine Components and Quality

Optical Components

Cost Implications

- High-Quality Optics: Superior materials, such as specialized coatings on lenses or high-precision mirrors, enhance beam accuracy and durability. These components increase the initial cost but result in consistent performance, reduced maintenance, and a longer operational life.

- Lower-Quality Optics: Less expensive optics may reduce the upfront cost but can lead to energy loss, frequent calibration, or premature wear and tear, increasing operational expenses over time.

Considerations

- Investing in high-quality optical components ensures optimal cleaning performance and a longer machine lifespan.

- Carefully evaluate the optical specifications to match the desired application and precision needs.

Cooling Systems

Cost Implications

- Water-Cooled Systems: These systems provide superior cooling performance, making them essential for high-power laser machines. While more effective at heat dissipation, they are more expensive due to the need for additional components, such as chillers and water circulation mechanisms.

- Air-Cooled Systems: Suitable for low to medium-power lasers, air-cooled systems are more affordable and simpler to maintain. However, they may be less effective for heavy-duty applications.

Considerations

- Choosing the right cooling system depends on the machine’s power output and intended usage.

- Proper cooling can extend the lifespan of key components and reduce the risk of overheating, improving the machine’s overall cost-efficiency.

Electronic Components

Cost Implications

- High-Quality Electronics: Reliable components from reputable manufacturers offer precise control, enhanced safety, and a reduced risk of electrical issues. These components increase the initial cost but contribute to long-term performance stability and fewer breakdowns.

- Standard or Low-Quality Electronics: Machines with lower-grade electronics may come at a lower purchase price but often face frequent malfunctions, higher maintenance needs, and potentially shorter service life.

Considerations

- High-quality electronics are essential for complex cleaning tasks that require precise adjustments and control.

- Evaluate the specifications and reputation of the electronic components used in the machine.

Mechanical Parts

Cost Implications

- Precision Engineering: High-quality mechanical parts designed with precision engineering enhance operational accuracy, reduce vibration, and increase durability. This precision comes at a premium cost but results in improved performance and longevity.

- Standard-Grade Parts: Machines with lower-quality mechanical components may be less expensive but could suffer from mechanical instability, faster wear, and reduced lifespan.

Considerations

- Assessing the quality of the machine’s mechanical structure helps determine its ability to withstand heavy use.

- Precision engineering contributes to consistent cleaning results and reduced wear over time.

Build Quality and Materials

Cost Implications

- High-Quality Materials: The use of stainless steel, reinforced frames, and corrosion-resistant coatings adds to the machine’s cost but ensures better structural integrity and resistance to environmental wear.

- Standard Materials: Machines built with lower-grade materials are typically more affordable but may be more susceptible to damage, wear, and maintenance needs over time.

Considerations

- Investing in superior build quality reduces the likelihood of breakdowns and costly repairs.

- Consider the operational environment and choose a machine designed to withstand specific conditions, such as exposure to harsh chemicals or varying temperatures.

Additional Accessories

Mobility Options

Cost Implications

- Portable and Handheld Units: Compact and lightweight designs often include wheels or ergonomic handles, making them easy to move. They offer excellent flexibility and are ideal for performing tasks in multiple locations or hard-to-reach areas.

- Stationary Units: They are suited for fixed cleaning stations where mobility is not a critical factor.

Dust Extraction Systems

Cost Implications

- Integrated Dust Extraction Systems: High-quality laser cleaning machines may include built-in dust extraction systems to maintain a clean and safe working environment. While these systems add to the upfront cost, they are essential for ensuring compliance with safety and environmental regulations, especially in industrial settings.

- External Dust Collection Systems: Machines may be paired with external dust collectors as an optional accessory. This can be more cost-effective but may require additional space and setup.

Safety Features

Cost Implications

- Advanced Safety Features: These may include safety enclosures, interlock systems, emergency stop buttons, protective eyewear, and sensors that automatically shut off the laser if the machine detects a breach of safety protocols. Machines equipped with comprehensive safety features often come with a higher price tag but offer enhanced protection and compliance with safety standards.

- Basic Safety Features: Machines with minimal safety mechanisms may be less costly but pose greater operational risks.

Brand and Manufacturer Reputation

Proven Track Record and Industry Experience

Cost Implications

- Well-Known Brands: Established brands often come with higher upfront costs, but these machines tend to offer superior reliability, consistent performance, and longer lifespans.

- New or Lesser-Known Brands: Machines from lesser-known manufacturers may be more affordable initially but could lack advanced features, robust construction, or reliable customer support.

Product Quality and Innovation

Cost Implications

- Innovative Features: Advanced technologies and unique features developed by top brands can significantly increase the cost but offer greater efficiency, durability, and adaptability to various cleaning applications.

- Standard or Entry-Level Features: More affordable machines from less established brands may lack the latest innovations, potentially reducing performance or limiting functionality.

After-Sales Support and Warranty

Cost Implications

- Premium Support Services: Higher-priced machines may include extensive customer support and warranty coverage, adding value and reducing long-term operational costs.

- Limited or Basic Support: Machines from manufacturers with limited after-sales support may be cheaper initially but could incur higher maintenance costs and increased downtime in the long run.

Global Recognition and Customer Feedback

Cost Implications

- Globally Recognized Brands: Machines from highly reputable brands may be priced higher due to their proven quality and reliability, reflected by positive customer feedback and industry accolades.

- Lesser-Known Brands: While potentially more affordable, these machines may carry unknown risks in terms of performance consistency, support, and long-term reliability.

Research and Development Costs

Innovation and Technological Advancements

Cost Implications

- Innovative Features: Machines with the latest technologies often command higher prices due to the additional costs associated with their development and implementation. However, these features often result in greater productivity, reduced maintenance requirements, and superior cleaning performance.

- Established Technologies: Machines based on older or less sophisticated technologies may be more affordable as their R&D costs have already been recouped over time.

Customization and Specialized Solutions

Cost Implications

- Customized Solutions: Machines tailored to specific applications, such as delicate restoration work, industrial rust removal, or high-precision cleaning, may involve higher R&D costs due to the need for specialized components and capabilities.

- Standard Models: More cost-effective because they are designed for general-purpose cleaning applications and benefit from economies of scale.

Continuous Improvement and Product Updates

Cost Implications

- Ongoing Improvements: Products that benefit from continuous R&D investments are often priced higher, reflecting their up-to-date technology and enhancements.

- Basic Models: Machines with minimal ongoing improvements may be less expensive initially but could become outdated more quickly or lack features that enhance operational efficiency and safety.

Cost of Patented Technologies

Cost Implications

- Patented Technologies: Machines featuring patented components or processes may cost more due to their exclusivity and the R&D expenses involved in their development.

- Non-Patented Technologies: Machines without proprietary technologies may be more competitively priced but might not offer the same level of performance or unique advantages.

Production Volume and Customization

Mass Production vs. Custom Builds

Cost Implications

- Mass Production: Machines produced in high volumes benefit from economies of scale, allowing manufacturers to reduce production costs and offer more competitive pricing. Standardized components and streamlined manufacturing processes result in consistent quality and reliability. These cost savings are often passed along to customers, making mass-produced models more affordable.

- Custom Builds: Customized laser cleaning machines are designed to meet unique needs or specifications. This often involves additional engineering, specialized components, and manual assembly processes, which increase production costs. Custom builds may also require more extensive testing and quality assurance, further contributing to the higher price.

Considerations

- Operational Needs: Businesses with specific cleaning requirements may find value in investing in a customized solution, despite the higher cost. Custom builds ensure the machine precisely meets operational demands, potentially leading to greater efficiency and long-term savings.

- Budget Constraints: For general-purpose cleaning tasks, a mass-produced model may offer a cost-effective solution with adequate performance.

Lead Times

Cost Implications

- Standard Models with Short Lead Times: Mass-produced machines are often readily available, resulting in shorter lead times. This can be especially advantageous for businesses with immediate needs, as shorter lead times minimize downtime and accelerate project timelines.

- Custom Builds with Extended Lead Times: Machines built to customer specifications typically require longer lead times due to the additional design, engineering, and testing involved. The extended wait time may lead to increased costs due to more complex planning and production processes.

Considerations

- Urgency of Requirements: If a rapid turnaround is needed, selecting a standard model with a shorter lead time may be more cost-effective.

- Flexibility in Scheduling: Businesses that can accommodate longer lead times may opt for a custom build to gain tailored features and improved performance, despite the higher price and wait.

Market Dynamics and Economic Factors

Supply and Demand

Cost Implications

- High Demand: Increased demand for laser cleaning machines, often driven by technological adoption in new industries, can lead to price increases due to limited supply.

- Low Demand: If demand decreases, manufacturers may offer discounts or promotions to encourage sales, reducing costs for buyers.

Currency Exchange Rates

Cost Implications

- Strengthened Local Currency: If the buyer’s local currency strengthens against the currency used by the manufacturer, the cost of importing the machine may decrease, resulting in savings.

- Weakened Local Currency: Conversely, if the local currency weakens, the cost of importing a laser cleaning machine may increase.

Tariffs and Taxes

Cost Implications

- High Tariffs: Import duties and taxes can increase the cost of acquiring a laser cleaning machine from an overseas manufacturer, making it more expensive for buyers.

- Tax Incentives: In some regions, governments may offer tax incentives or subsidies for the purchase of environmentally friendly or energy-efficient equipment, reducing the cost for buyers.

Inflation and Material Costs

Cost Implications

- Increased Material Costs: Rising prices for key materials like aluminum, carbon steel, stainless steel, and optical components can lead to higher production costs, which are reflected in the price of the final product.

- Inflationary Pressures: General inflation trends can also lead to increased costs for labor, transportation, and other operational expenses, further raising prices.

Certification and Compliance Standards

Safety Standards

Cost Implications

- Comprehensive Safety Measures: Machines that meet stringent safety standards often include features such as safety enclosures, interlock systems, emergency stop buttons, and sensors that monitor the operational environment. These components add to the manufacturing cost but are essential for operator safety and regulatory compliance.

- Certification Costs: Achieving compliance with international safety standards, such as those from the International Electrotechnical Commission (IEC) or Occupational Safety and Health Administration (OSHA), may involve additional testing and certification expenses, contributing to the overall cost.

Considerations

- Investing in machines that adhere to robust safety standards helps ensure a safe working environment and reduces the risk of workplace accidents.

- Compliance with recognized safety standards is often mandatory for certain industries, making it a critical consideration when purchasing a machine.

Industry-Specific Regulations

Cost Implications

- Tailored Solutions: Machines designed to meet industry-specific standards, such as those used in aerospace, medical, or automotive applications, may require specialized features, materials, or certifications. This customization increases the cost.

- Compliance Testing: Additional testing and documentation may be required to ensure compliance with industry standards, adding to the production costs.

Considerations

- Businesses should be aware of any industry-specific regulations that apply to their operations and ensure that the chosen laser cleaning machine complies fully with these requirements.

- The cost of a compliant machine may be higher initially, but it can help avoid regulatory fines, enhance credibility, and improve operational efficiency.

Environmental Regulations

Cost Implications

- Eco-Friendly Designs: Machines that comply with environmental regulations may incorporate features like efficient dust extraction systems, reduced energy consumption, and minimal waste generation. These enhancements can increase the initial cost but help align with sustainability goals.

- Regulatory Compliance Costs: Meeting environmental regulations, such as those set by the Environmental Protection Agency (EPA) or similar agencies in different countries, may involve additional documentation, testing, and design considerations.

Considerations

- Investing in environmentally compliant machines not only ensures regulatory adherence but also supports corporate sustainability initiatives and reduces the environmental impact of cleaning operations.

- Businesses operating in regions with strict environmental standards should prioritize machines that align with these regulations to avoid penalties and minimize environmental liabilities.

Shipping and Import Costs

Logistics

Cost Implications

- Shipping Method: Air freight offers faster delivery but at a higher cost compared to sea freight, which is more economical but has longer transit times. The choice of shipping method depends on the buyer’s urgency and budget.

- Distance and Destination: Shipping costs increase with greater distances and if the destination is in a remote or less accessible area. Importing a machine across international borders can also involve additional expenses, such as customs clearance fees and duties.

- Carrier Services: The cost and reliability of logistics services vary by carrier. High-quality services with specialized handling and tracking capabilities may come at a premium but ensure better security and on-time delivery.

Considerations

- Buyers should carefully evaluate logistics options based on delivery timelines, costs, and reliability.

- Importing a laser cleaning machine from another country may also require compliance with import regulations, customs duties, and taxes, further affecting the total shipping cost.

Packaging

Cost Implications

- High-Quality Packaging Materials: Laser cleaning machines are often packaged using heavy-duty crates, protective padding, moisture-resistant barriers, and shock-absorbent materials to prevent damage during shipping. While this type of packaging offers superior protection, it increases overall shipping costs.

- Standard Packaging: For shorter, less complex shipping routes, manufacturers may use simpler packaging solutions that are less costly but may offer reduced protection.

Considerations

- Investing in high-quality packaging helps reduce the risk of damage during transit, minimizing potential repair or replacement costs.

- Buyers should confirm that the packaging meets international shipping standards, especially when importing machines from abroad.

Training, Installation, and Maintenance

Professional Installation

Cost Implications

- Installation Fees: Professional installation adds to the initial cost but is essential for maximizing efficiency and preventing potential issues caused by improper setup.

- Reduced Downtime: Expert installation minimizes downtime, as the machine is correctly configured from the start, reducing the risk of operational errors or future repairs.

Considerations

- Investing in professional installation can lead to long-term cost savings by ensuring optimal performance, safety, and minimal disruption during the initial setup phase.

Operator Training

Cost Implications

- Training Programs: The cost of training varies depending on the level of instruction and whether it is conducted on-site or remotely. High-quality training programs may increase the upfront cost but reduce the risk of operational errors and accidents.

- Improved Efficiency: Well-trained operators can maximize the machine’s capabilities, leading to improved productivity and reduced downtime.

Considerations

- Investing in thorough operator training helps prevent costly mistakes, enhances safety, and ensures efficient use of the machine.

Maintenance Plans

Cost Implications

- Comprehensive Maintenance Plans: These plans cover a wide range of services and are often offered by the manufacturer or a trusted service provider. While more expensive upfront, they can reduce the likelihood of unexpected breakdowns and costly repairs.

- Basic Maintenance Services: Less comprehensive plans may be more affordable but might not cover all potential issues, increasing the risk of unplanned downtime.

Considerations

- Assess the maintenance requirements and coverage options offered by the manufacturer. A comprehensive plan may be more cost-effective in the long run, reducing unexpected expenses and keeping the machine running smoothly.

Upkeep and Consumables

Cost Implications

- High-Quality Consumables: Premium consumables may come at a higher cost but offer better durability and performance, reducing the frequency of replacements.

- Regular Upkeep Costs: Routine upkeep requires time and resources, but neglecting maintenance can lead to performance degradation and potential damage, resulting in more significant expenses.

Considerations

- Factoring in the cost of consumables and routine upkeep helps provide a realistic view of the total cost of ownership.

- Choosing high-quality parts and adhering to regular maintenance schedules can prevent costly repairs and extend the machine’s lifespan.

After-Sales Service and Support

Warranty Coverage

Cost Implications

- Comprehensive Warranties: Machines with longer and more inclusive warranties may come with a higher initial cost. However, these warranties reduce the risk of unexpected expenses due to repairs or component failures, providing significant long-term value.

- Limited Warranties: Machines with shorter or less comprehensive warranties may be less expensive upfront but could lead to higher repair and maintenance costs over time if issues arise outside the warranty period.

Considerations

- Assess the warranty coverage offered by different manufacturers, focusing on its duration, inclusions, and any potential limitations.

- Investing in a machine with a comprehensive warranty often results in lower long-term costs and greater operational reliability.

Technical Support

Cost Implications

- 24/7 Support Services: Manufacturers that offer around-the-clock technical support or dedicated customer service may charge a premium for these services. However, prompt assistance can prevent extended downtime and costly interruptions to operations.

- Standard Support Options: Basic technical support services may be more cost-effective but could involve limited availability, slower response times, or less personalized assistance.

Considerations

- Evaluate the level of technical support provided, including response times, availability, and the expertise of support staff.

- Investing in high-quality technical support services can enhance productivity and reduce costs associated with machine downtime.

Maintenance Services

Cost Implications

- Comprehensive Maintenance Plans: These plans offer regular, scheduled maintenance and may include parts replacement, system diagnostics, and performance optimization. While more expensive upfront, comprehensive plans reduce the risk of unexpected breakdowns and extend the machine’s lifespan.

- Ad-Hoc Maintenance Services: Pay-as-you-go maintenance services may be more affordable initially but can become costly if frequent repairs are needed.

Considerations

- Consider the maintenance options offered by the manufacturer and choose a plan that aligns with your operational needs and budget.

- Comprehensive maintenance plans often lead to long-term savings by reducing repair costs and maximizing machine uptime.

Training and Documentation

Cost Implications

- In-Depth Training Programs: These programs may include on-site training, virtual training sessions, or specialized workshops. While they add to the initial cost, well-trained operators can increase productivity, reduce errors, and improve overall machine performance.

- Basic Training and Limited Documentation: Lower-cost machines may come with limited training or documentation, potentially leading to a steeper learning curve and increased operational risks.

Considerations

- High-quality training and detailed documentation empower operators to use the machine safely and effectively, reducing the risk of accidents and operational errors.

- Investing in thorough training programs can lead to long-term productivity gains and cost savings.

Summary

Get Laser Cleaning Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.