What Are The Factors That Affect The Cost of Laser Marking Machine

The rise of laser marking technology has brought a technological revolution to industrial production. As the key equipment in this field, the cost of laser marking machines is directly related to the investment decisions and production efficiency of enterprises. In this highly competitive market, it is crucial to understand the factors that affect the cost of laser marking machines.

This article will delve into these factors, including discussing the working principle of laser marking machines, the cost of laser marking machines, and how industry, market, and technology affect laser marking costs. Expand knowledge of this critical technology to help businesses better understand how to strike a balance between technology and economics.

Table of Contents

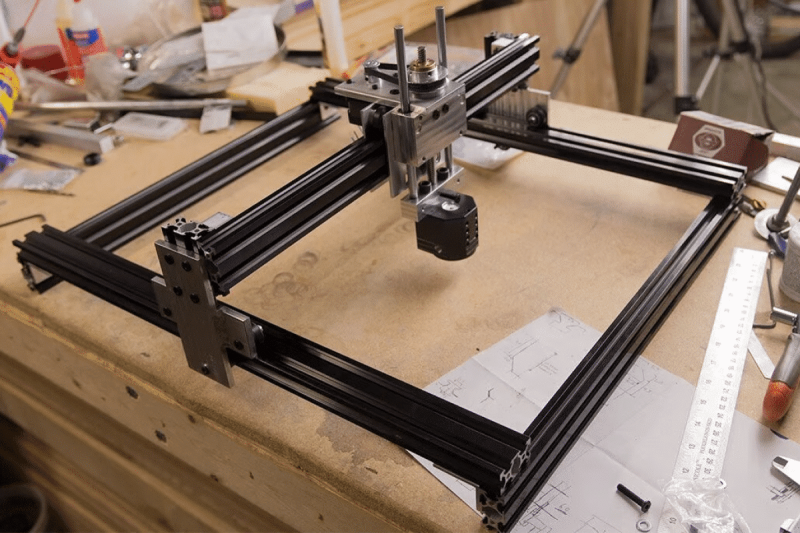

Working principle of laser marking machine

Laser marking is a high-precision processing technology that uses laser beams to mark the surface of objects. Its basic principles involve key steps such as laser emission, focusing, and acting on the surface of the object. The specific principles are as follows:

- Laser emission: Laser generation usually uses gas laser generators, solid laser generators, or semiconductor laser generators as laser sources. The laser beams generated by these laser generators are highly monochromatic and coherent, providing a stable and controllable light source for subsequent marking.

- Laser modulation: In laser marking, the intensity of the laser beam needs to be modulated. Modulation can be achieved through light interference, gratings, or modulators to ensure that the laser can accurately mark according to the required pattern.

- Beam focusing: The laser beam is focused through optical elements such as lenses or mirrors to minimize the spot on the surface of the object, thereby increasing the energy density. The focused laser spot can act on the object surface more accurately to achieve high-resolution marking.

- Energy effect: When the laser beam acts on the surface of an object, its high energy density will cause local heating of the material. This action can have different effects on different materials, including scoring, melting, or vaporizing to create clear marks.

- Control system: The laser marking system is equipped with a sophisticated control system, which can accurately control the trajectory of the laser beam on the surface of the object according to the preset pattern, text, or code. Through computer control, a high degree of automation and flexibility can be achieved to adapt to various marking needs.

The basic principles of laser marking have been widely used in industrial manufacturing, medicine, electronics, and other fields. Its high precision and high efficiency make it an indispensable tool in modern manufacturing.

How much does a laser marking machine cost?

The cost of a laser marking machine varies based on a variety of factors, including equipment model, laser technology, manufacturing materials, production processes, and more. Therefore, a specific fixed value cannot be provided. However, some rough estimates and generalities can be provided:

Small desktop laser marking machine

Small, desktop laser marking machines are usually used in small-scale production or individual work scenarios. The price of such devices may be between$2000 and $6000, depending on the brand and functional configuration.

Industrial grade laser marking machine

The cost of industrial-grade laser marking machines for mass production and higher marking accuracy requirements can be higher. The price of such equipment is usually ranging between $ 5000 and $ 8000, depending on factors such as laser power, marking speed, and degree of automation.

High-end laser marking system

For some specific industries and high-end applications, higher performance and more complex laser marking systems may be required. The cost of such systems may exceed $ 100,000 or even higher, depending on the technical specifications and additional functions.

Additional fees

In addition, additional costs need to be considered when purchasing a laser marking machine, such as installation costs, training costs, after-sales service costs, etc. These fees may have some impact on the overall investment.

The cost of laser marking machines directly affects return on investment and production costs. Based on understanding costs, enterprises can better formulate reasonable investment plans and balance technical requirements and economic benefits. Therefore, an in-depth understanding of the cost structure of laser marking machines is crucial for companies to make informed decisions.

Own factors affecting the cost of laser marking machines

As an efficient and accurate marking equipment, laser marking machines have been widely used in industrial manufacturing, medical equipment, electronic products, and other fields. Its cost is directly related to corporate investment decisions and production efficiency. Understanding the factors that affect the cost of laser marking machines is crucial for companies to choose the appropriate equipment and optimize the production process. The following are the main factors that affect the cost of laser marking machines:

Laser efficiency

The laser power of a laser marking machine is one of the key factors that determines its marking effect and speed. High-power laser marking machines usually achieve deeper marks, and at the same time, the marking speed is faster, but this is also accompanied by higher equipment costs.

Marking accuracy and resolution

For some applications that require highly precise marking, such as marking electronic components, laser marking machines are required to have high accuracy and resolution. This involves more advanced optical systems and sophisticated control technology, thus increasing equipment costs.

Marking speed

In some production environments, completing markup quickly is critical. The high-speed marking capabilities of laser marking machines may require more powerful laser sources and faster control systems, thus also increasing costs.

Laser source and optical lens quality

The quality of the laser source and the accuracy of the optical lens directly affect the quality and stability of the laser beam. Using high-quality laser sources and optics increases device reliability and longevity, but it also means higher manufacturing costs.

Degree of automation

As the degree of automation in the manufacturing industry continues to increase, the demand for automation equipment is also increasing. Automated laser marking machines are usually equipped with advanced control systems and automation functions, but this will increase the price of the equipment.

Design and manufacturing processes

The complexity of the manufacturing process is directly related to the manufacturing cost of the device. The use of advanced manufacturing processes and high-quality parts can improve the stability and life of the equipment, but it will also bring higher costs.

Balance between cost and performance

Businesses need to balance cost and performance when choosing a laser marking machine. Understanding the specific impact of each factor on cost can help businesses better select equipment that meets their needs.

The impact of technological development on costs

The introduction of new technologies and continuous technological innovation have an impact on the cost of laser marking machines. New technologies may improve device performance, but they may also increase manufacturing complexity and cost.

An in-depth understanding of these factors in the cost of laser marking machines is crucial for companies to formulate scientific investment plans, improve production efficiency, and reduce manufacturing costs. Choosing a laser marking machine with an appropriate cost can help companies gain an advantage in the fierce market competition and ensure that the equipment can meet the needs of specific industries.

Other factors affecting the cost of laser marking machines

In addition to the parameters, efficiency, and technology of the laser marking machine itself, factors affecting its cost also involve industry application requirements, market competition, and supply chain. The following is a detailed description of these two aspects:

The impact of industry application requirements on costs

Different industries have very different technical requirements, degrees of customization, and performance requirements for laser marking machines. The following are the main factors affecting the cost of laser marking machines based on industry application requirements:

- The degree of technical customization: Different industries have huge differences in the degree of technical customization of laser marking. For example, medical equipment or aerospace may have extremely high requirements for the accuracy and clarity of markings, so a higher-precision laser marking machine is needed.

- Material diversity: There are also great differences in the materials used in different industries, including metals, plastics, ceramics, etc. Laser marking machines need to adapt to the characteristics of different materials, which may require more complex laser systems and optical configurations, thus increasing costs.

- Production scale and efficiency needs: In large-scale production, faster marking speeds and higher levels of automation may be required. The industry’s production scale and demand for efficiency will also directly affect the cost of laser marking machines.

- Marking depth and marking method: Industries have different requirements for marking depth and marking method. Different requirements may require different types of laser sources and adjustments, and some industries may require deep etching while others may focus more on the surface clarity of marks.

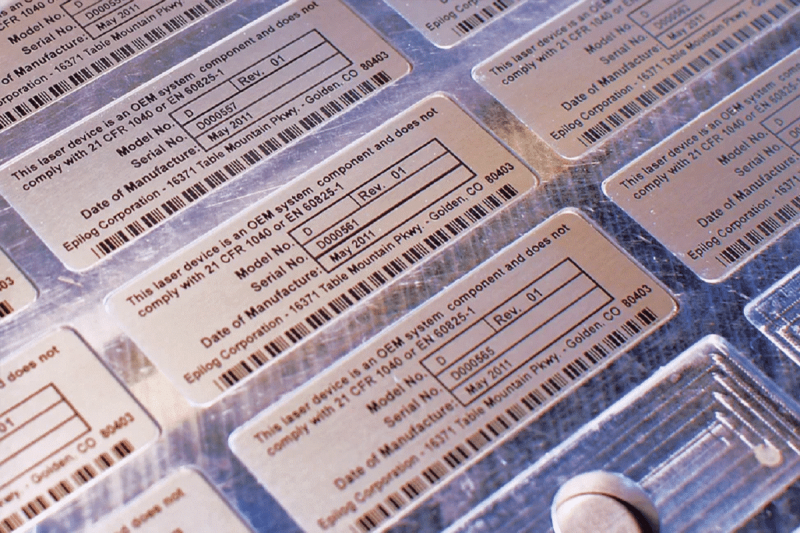

- Traceability and quality control: In some industries such as food safety and medical devices, there are extremely high requirements for product traceability and quality control. This may require more sophisticated marking technology and equipment to ensure each product is uniquely identified.

- Application complexity: The application complexity of laser marking machines in different industries is also different. Highly complex applications may require more advanced control systems and software to accommodate complex marking patterns and requirements, which may increase equipment costs.

- Environmental requirements: The production environment of different industries may have strict requirements, such as sensitivity to dust, humidity, and temperature. Laser marking machines need to be customized according to specific environments to meet special working conditions, which may also increase costs.

The impact of market competition and supply chain on costs

Market competition and supply chain are two key factors that affect the cost of laser marking machines. The dynamic relationship between the two directly affects the price of equipment and the cost structure of the enterprise. The following are the main influencing factors of market competition and supply chain on the cost of laser marking machines:

The impact of market competition on costs

- Price competition: To compete for market share, different manufacturers may adopt different price strategies, including lowering selling prices, providing additional services or value-added functions, etc. This competition may affect price levels across the market.

- Product feature competition: Manufacturers may differentiate their products by offering more advanced technical features, higher performance levels, or more innovative features. This may lead to an increase in the price of some high-end devices, while also pushing the market to a higher level.

- Economies of scale: Manufacturing on a large scale often reduces the cost of producing a unit of product. The dominant manufacturer in the market may be able to offer more competitive prices due to its economies of scale. Smaller manufacturers may require higher production costs, so the selling price of the equipment may be relatively high.

Impact of supply chain on costs

- Raw material costs: The manufacturing of laser marking machines involves various raw materials, including laser sources, optical components, control systems, etc. Price fluctuations of raw materials in the supply chain will directly affect the manufacturing cost of the equipment. A stable supply chain can help reduce instability and ensure cost controllability.

- Supply chain reliability: A highly reliable supply chain helps avoid production disruptions and reduced productivity.

- Innovation-driven costs: Technological innovations often increase production efficiency, but the initial development and implementation of new technologies can result in higher costs for equipment. As the technology matures, costs are likely to fall.

If market demand changes rapidly, manufacturers may need more flexible production and supply chains to adapt to these changes. Under the influence of market competition and supply chains, manufacturers need to carefully weigh costs and market competitiveness.

Summarize

Enterprises should consider these factors more comprehensively in investment decisions to achieve a balance between cost and performance. Cost management is crucial to the competitiveness of an enterprise, and the introduction of technological innovation can reduce the overall cost of laser marking machines to a certain extent.

Generally speaking, the factors affecting the cost of laser marking machines cover multiple levels such as technology, industry demand, market competition, and supply chain. An in-depth understanding of these factors can help companies make more informed investment decisions to meet the needs of different industries and remain competitive in fierce market competition.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions