What Are The Factors That Affect The Price of Laser Welding Machines?

Laser welding machines have revolutionized the welding industry with their precision, speed, and versatility. However, the prices of different models and configurations of laser welding machines are huge, which makes price one of the key considerations when purchasing a laser welding machine. What factors lead to the price difference between these laser welding machines? How should we choose a cost-effective laser welding machine?

This article aims to provide an understanding of laser welding machine prices, including the principles of laser welding, the factors that affect them, the price ranges available, and important considerations when evaluating the cost of a laser welding machine. By delving into these aspects, readers will gain an understanding of the pricing environment and make informed decisions based on their specific requirements and budget.

Table of Contents

What is laser welding machine?

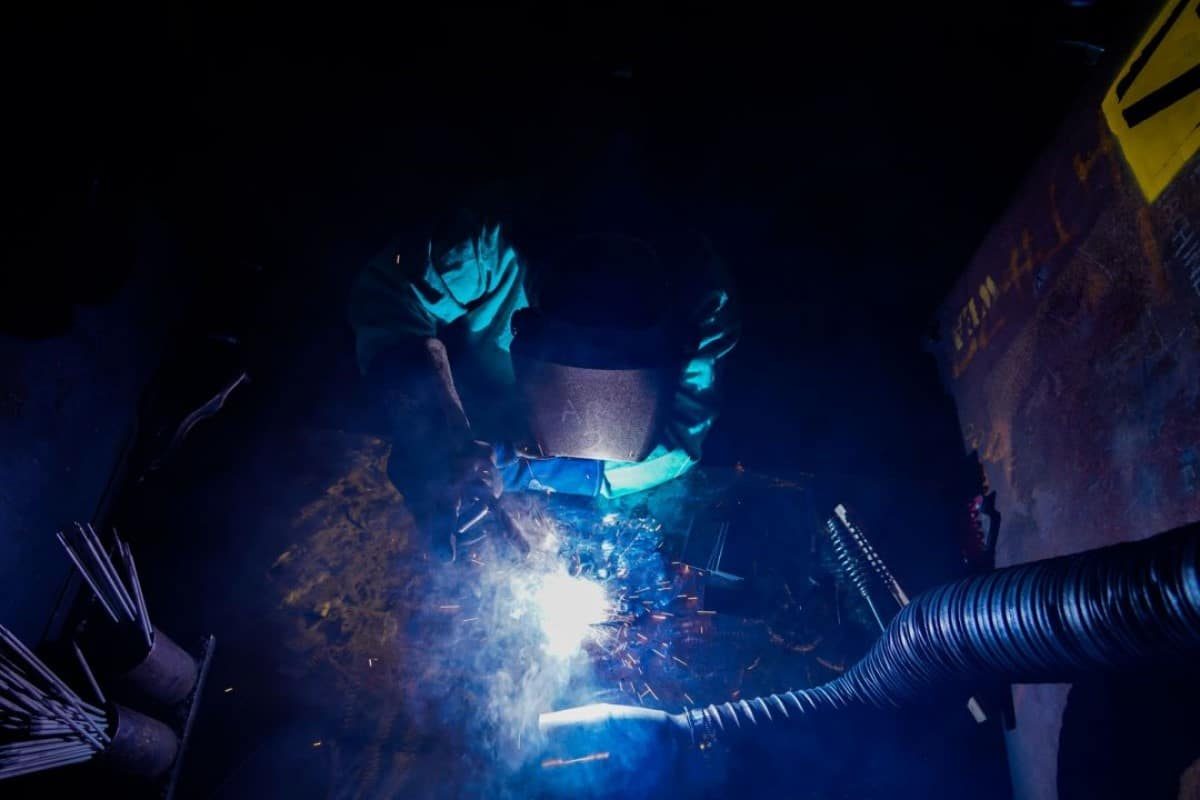

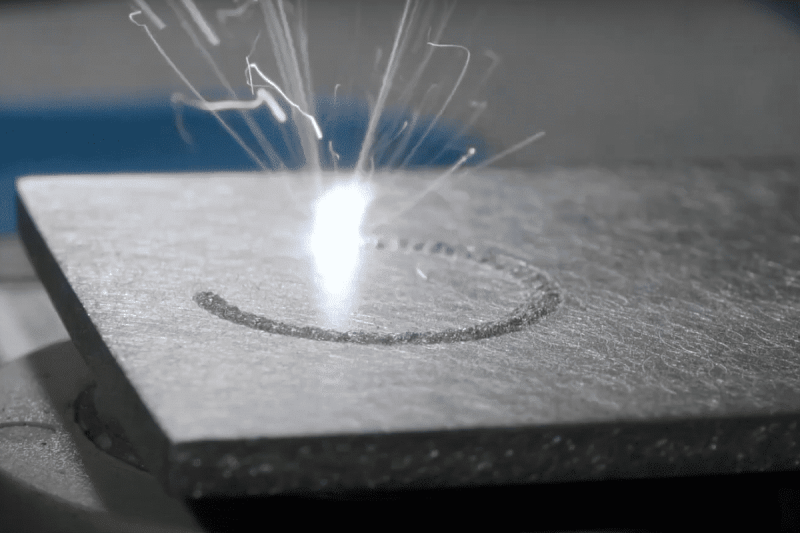

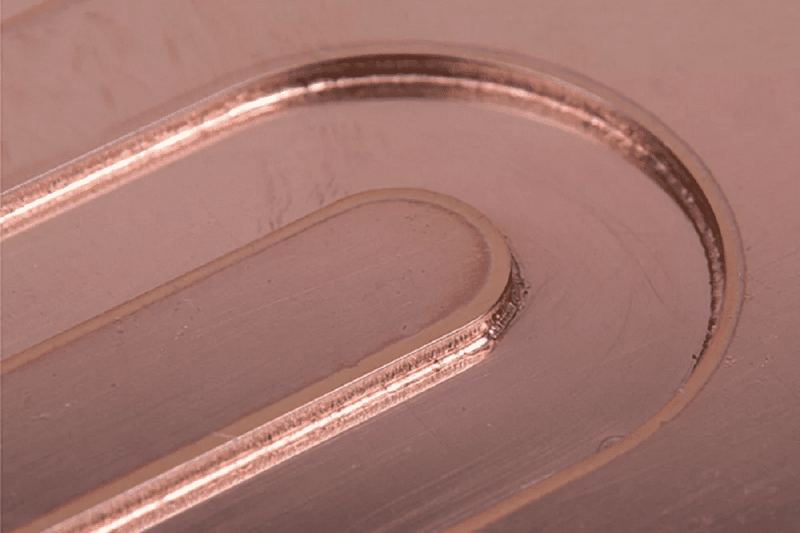

Before understanding the price of a laser welding machine, let us first understand what a laser welding machine is. A laser welder is a highly specialized piece of equipment that uses a focused laser beam to melt and fuse materials. It works by directing a high-intensity laser beam onto the surfaces to be joined, creating a precise and controlled heat source that creates strong, clean welds. Laser welding usually uses carbon dioxide laser, fiber laser, or diode laser.

The following is the basic working principle of laser welding:

- Laser source: Commonly used laser sources include carbon dioxide laser generators, fiber laser generators, and diode laser generators. These laser sources are capable of producing monochromatic, highly coherent, and highly directional laser beams.

- Beam focusing: The laser beam needs to be focused through a lens or reflector to concentrate the energy of the beam into the welding area to quickly heat the workpiece.

- Absorption and conduction: After the laser beam irradiates the surface of the workpiece, the energy will be absorbed by the workpiece instead of reflected. The extent to which laser energy is absorbed depends on the type and color of the material.

- Melting and fusion: The high energy density of the laser beam will quickly heat the welding area above the melting point, causing the workpiece material to melt instantly.

- Cooling and solidification: Once the laser beam stops irradiating, the welding area cools rapidly and the molten metal solidifies. The workpieces have been firmly connected.

Laser welding machine price range

Welding is an indispensable process in metal processing. Therefore, the market for laser welding machines has expanded, and more and more consumers are accepting laser welding machine equipment. Price is what consumers are most concerned about. Machines with different prices are mainly summarized into the following three types:

Entry-level and compact machines

Entry-level laser welding machines are usually relatively low-priced and suitable for small businesses or individuals who are new to laser welding technology. These machines typically have lower laser power. Prices generally range from $5,000 to $10,000, depending on the manufacturer, model and configuration. These machines may be suitable for low-volume, low-demand welding tasks, but may not perform well in large-scale and demanding industrial applications.

Mid-range machine

Mid-range laser welding machines usually have higher performance and features and are suitable for medium-sized enterprises and some specific industrial applications. These machines typically have moderate to high laser power, higher welding accuracy, and more configuration options. The price range is generally between US$10,000 and US$30,000 but may be higher, and the specific price is affected by technical parameters, manufacturer, optical system, and control system. Mid-range machines are generally suitable for medium-scale production and more demanding welding tasks and can provide high efficiency and accuracy.

Industrial grade and high-end machines

Industrial high-end laser welding machines are the most advanced and powerful machines on the market, specifically designed for large-scale industrial manufacturing and demanding applications. These machines typically feature the highest laser power, state-of-the-art optics, sophisticated control systems, and a wide range of configuration options. They can handle a variety of complex welding tasks, including large workpieces, high-speed production, and high-precision requirements. Prices typically range from $30,000 upwards, depending on model and customization options. Industrial high-end laser welding machines are usually produced by large industrial manufacturers that provide comprehensive after-sales support and maintenance services.

It should be noted that these prices are for reference only and actual prices may vary due to market demand, technological innovation, and supplier strategies. When purchasing a laser welding machine, you need to consider your needs, budget, and required performance and features, then compare with multiple vendors to find the equipment that works best for you.

Factors affecting the price of laser welding machine

Laser welding technology is an important welding method in modern manufacturing and is widely used in various industries. Its price is affected by many factors. The following are specifically listed:

Laser Source Technology and Power

Laser source technology and power play an important role in determining the price of a laser welding machine. Different laser generator types, such as fiber lasers, CO2 lasers, and solid-state lasers, vary in cost and performance. Higher-power laser generators generally have a higher price, so in applications where large workpieces need to be processed or high-speed production, high-power equipment may be necessary. However, for small workpieces or precision welding tasks, lower-powered equipment may be sufficient and relatively inexpensive.

Welding machine equipment configuration

The size of the welding area and equipment configuration will also affect the price of the laser welding machine. Prices are relatively high for machines with large work areas and flexible machine configurations such as robotic arms or multi-axis systems. Machines equipped with advanced functions such as beam transmission systems, motion control systems, and real-time monitoring will also reduce many costs, such as labor and maintenance costs.

Manufacturing and Branding

The prices of laser welding machines produced by different brands and manufacturers will also vary. Well-known brands typically have greater market recognition and reputation, and offer comprehensive customer support, warranty coverage, and after-sales service. Their equipment prices may therefore be higher. Some small or emerging manufacturers may also offer more competitive prices. But it’s important to evaluate specific features, performance, and reliability beyond the brand name, and you still need to choose carefully to ensure the quality of the equipment and after-sales service.

Automation and integration capabilities

Laser welding machines with automated and integrated features such as CNC controls, robotic arms, or custom software interfaces may have a higher price tag. Different application fields have different requirements for equipment performance and specifications. For example, medical device manufacturing and automobile manufacturing often require high-precision and high-efficiency equipment. Advanced functions increase productivity, accuracy, and repeatability, making them suitable for large quantities. production and complex welding applications. This in turn causes prices to rise.

Market demand and competition

Market competition and regional differences will also affect the price of fiber laser welding machines. In a highly competitive market, manufacturers may lower prices to attract customers, thereby affecting the price level of the entire market. In addition, the price of equipment may also differ in different regions, affected by factors such as transportation costs, tax policies, and market demand.

Warranty and after-sales service

After-sales service and warranty are important factors to consider when purchasing a fiber laser welding machine. Different manufacturers offer varying levels of after-sales support and warranty policies, which will affect the total cost of ownership of the device. In some cases, additional warranty and service costs may affect the price of the equipment, but may also provide additional security and reliability.

To sum up, various factors affect the price of fiber laser welding machines. All aspects from technical parameters to equipment configuration, brand and manufacturer, application fields, market competition, and after-sales service may have an impact on the price.

Things to consider when evaluating the cost of a laser welding machine

When evaluating the cost of a laser welding machine, there are some key considerations to consider to ensure you make an informed decision:

Welding efficiency and performance

The efficiency and performance of a laser welding machine should be the primary consideration when evaluating its cost. Machines that offer higher welding speeds, precise control, and consistent weld quality may cost more, but provide better overall value by reducing welding time, minimizing rework, and increasing productivity.

Maintenance and operating costs

It is crucial to evaluate the maintenance and operating costs associated with your laser welding machine. The operating costs of a laser welding machine include energy costs, maintenance fees, material costs, and operating and maintenance personnel costs. Additionally, inquire about the availability and cost of technical support, spare parts, and services to ensure long-term sustainability and minimize unexpected expenses.

Welding application requirements

Evaluate the specific requirements of your welding application. Be sure to estimate the cost of the required materials and understand how their availability affects the cost estimate. Some laser welding machines may offer specialized features or compatibility with certain materials or joint configurations, which may also affect their price. Consider whether these specific features meet your welding needs, or if there are more cost-effective options that may meet the requirements.

Return on investment

Consider the machine’s potential ROI by evaluating its impact on productivity, labor costs, material savings, and weld quality. A higher-priced machine with significant advantages and cost savings may provide a better long-term investment. Efficient laser welding machines can complete more work in the same amount of time, thereby increasing productivity. This may offset some of the machine’s high purchase costs.

Summarize

The price of a laser welding machine is affected by many factors. Understanding these factors can help you better understand why the prices of different models and specifications of laser welding machines vary greatly. When choosing a laser welding machine, you need to consider your specific needs, application area, and budget to choose the equipment that is best for you.

By gaining an in-depth understanding of these factors, you can better understand the laser welding machine market and make informed purchasing decisions. Whether you are a manufacturer or end user, you should carefully consider these factors when purchasing a laser welding machine to meet your specific needs and budget.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions