Precautions for Electrical System

When using a laser welding machine, electrical safety is very important, so electrical installation needs to be carried out in strict accordance with the machine instruction manual. When operating the machine, always pay attention to electrical operating safety.

- It is strictly prohibited to damage the power supply or step on, twist, or pull the cable. Damage to the cable may cause electric shock, short circuit, fire, and other dangers.

- When there is a burning smell, abnormal sound, abnormal heat, smoke, or other abnormal phenomena near the machine, please turn off the power of the laser welding machine immediately to stop operation, otherwise there will be dangers such as electric shock, fire, etc.

- Foreign objects, especially metal or conductive objects, should be avoided inside the circuit to prevent short circuits or malfunctions. Contact with water in the electrical part may cause an electric shock or short circuit, so do not use the laser welding machine in a humid environment.

- When the laser welding machine does not need to be working, do not connect it to the power supply.

- When the control board is powered on, the bottom of the board cannot directly contact the metal surface.

Precautions for Machine Operating Environment

The operating environment of the laser welding machine is equally important to the normal use of the machine. A good operating environment can extend the service life of the machine. Here are some things to note:

- Do not place flammable or explosive materials on the laser light path or where the laser beam can be irradiated to avoid causing fires and explosions.

- It is recommended to set up a dedicated laser welding area and place safety signs in the welding area.

- The laser welding machine should be installed in a level and stable place. It is prohibited to use it in an inclined place.

- Please use the laser welding machine in an environment with an ambient temperature of 5°C to 30°C and a humidity of ≤35%. At the same time, pay attention that the ambient temperature should not fluctuate too much.

- It is prohibited to use laser welding machines in the following environments: environments with oil pollution, environments with vibration, environments with corrosion, environments with high-frequency noise, environments with humidity, and environments containing high concentrations of carbon, nitrogen, and sulfur oxides (CO2, NOX, SOX) environment.

- In winter, if the ambient temperature drops below 0℃, the water in the water tank will freeze and the water tank may freeze. Therefore, special attention should be paid to ensuring that the ambient temperature of the laser welding machine does not fall below 0°C in winter. If the ambient temperature drops below 0℃, please drain the water in the water tank first.

Precautions for Machine Operation

Before starting a laser welding project, please read the fiber laser welding machine instruction manual carefully or participate in relevant training to ensure that the operator can use the machine correctly. Correct operation can help users obtain high-quality welding parts while ensuring that all processes are safe.

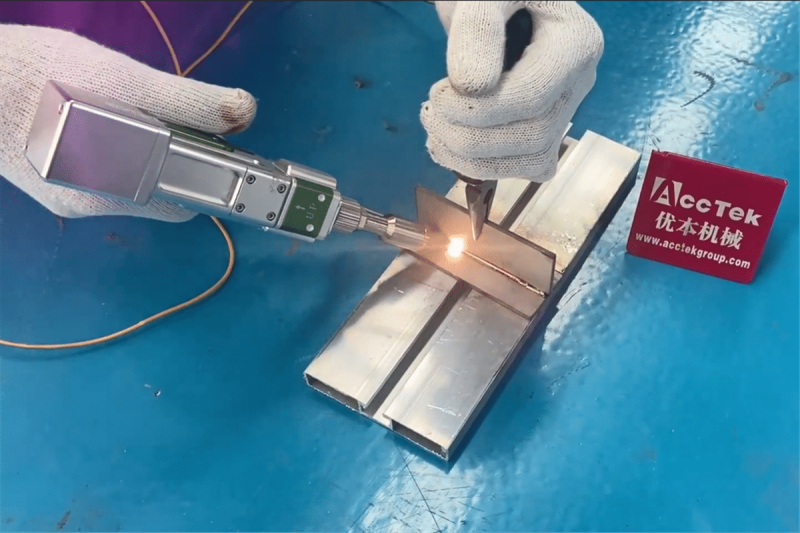

- Laser welding machine operators need to wear laser-protective glasses and safety gloves during work. After the machine is powered on and the laser power is turned on, it is strictly forbidden to point the laser welding gun toward the human body and eyes. After welding, because the workpiece is still at high temperature for a short period, you need to wear gloves to touch the workpiece to avoid burning your hands.

- When using the laser welding gun, try to tilt it at an angle that can extend the service life of the protective lens. Handle it with care during use, and it is strictly forbidden to drop the laser welding head to avoid damage to the internal lens.

- When the laser welding head heats up and the output energy becomes smaller, stop using it immediately and check whether the protective lens is damaged in time. It is strictly forbidden to try to use the machine without normal output energy. This will burn out the laser welding gun and even cause harm to the operator’s safety.

- After the protective lens is damaged, it should be replaced in time to avoid damaging the optical lens of the swing system. During the laser welding process, qualified pure gases (nitrogen, argon), reasonable gas pressure (5-10Mpa), and reasonable gas flow (at least 15L/min) need to be used. It is prohibited to use the machine without protective lenses and air blowing.

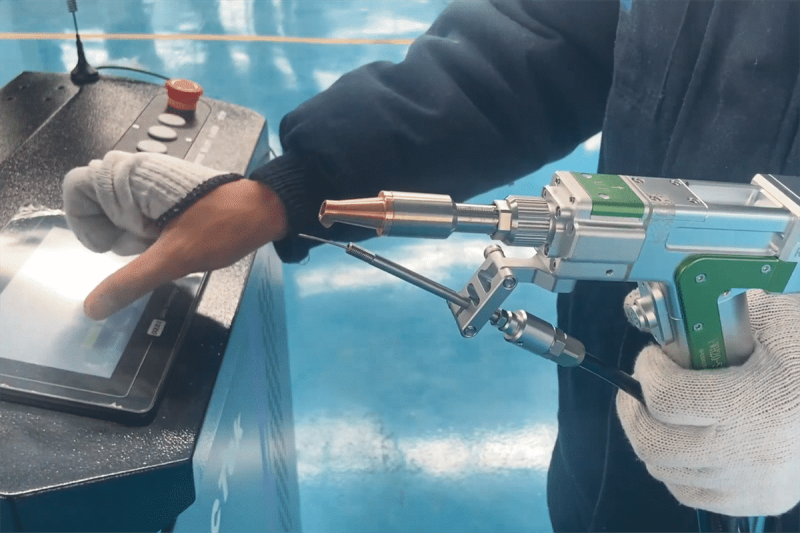

- When using the laser welding machine for a long time, you need to frequently check whether the laser guide light of the nozzle is in the center of the light outlet. If the guide light is not in the center of the light outlet, you can click the correction button on the system interface to enter the correction interface to adjust the guide light source so that it re-enters the center of the light outlet.

- If the copper nozzle burns red during laser welding, you need to stop working and check whether the inner wall of the copper nozzle is smooth. If it is not smooth, you need to replace the copper nozzle. If the inner wall of the copper nozzle is smooth, you need to check whether the red light is in the center of the copper nozzle. If it is not in the center, please contact the laser welding machine manufacturer to solve the problem.

- When the machine is working, the circuit is in a high-voltage and high-current state. It is strictly prohibited to touch the circuit components in the machine while it is working.

- In high-temperature or humid environments, when the laser welding machine is running, you should always pay attention to observing whether there is “condensation” caused by too low water temperature on the cooling water circulation pipe or the laser focusing cavity. The appearance of “condensation” will affect the laser generator, causing the output power to decrease or even no light to be emitted. You must pay attention to it during use.

- Operators can often use black paper to check the output spot of the laser welding machine. Once the spot is found to be uneven or the energy is reduced, the resonant cavity should be adjusted in time to ensure the beam quality of the laser output.

Precautions for Installation and Debugging

When installing and debugging the laser welding machine, it is necessary to designate an operator with sufficient experience in laser equipment and electrical knowledge. In addition to ensuring safety, experienced operators can adjust the machine to the best condition, which ensures higher efficiency and better welding quality. When installing and debugging a laser welding machine, you need to pay attention to the following points:

- The circuit plug needs to be pulled out and plugged in carefully. Careless operation will cause damage to the circuit board of the laser welding machine. At the same time, make sure that the wire connectors are in good contact.

- The handheld laser welding gun must have a water flow rate of greater than 1 liter per minute and less than 1.5 liters per minute. The laser water pressure is 20 liters per minute. Good cooling can ensure the normal operation of the machine.

- The air knife pressure and nitrogen pressure should be greater than 5Mpa and less than 10Mpa, and the bending radius of the optical fiber should be greater than 15cm during use and placement.

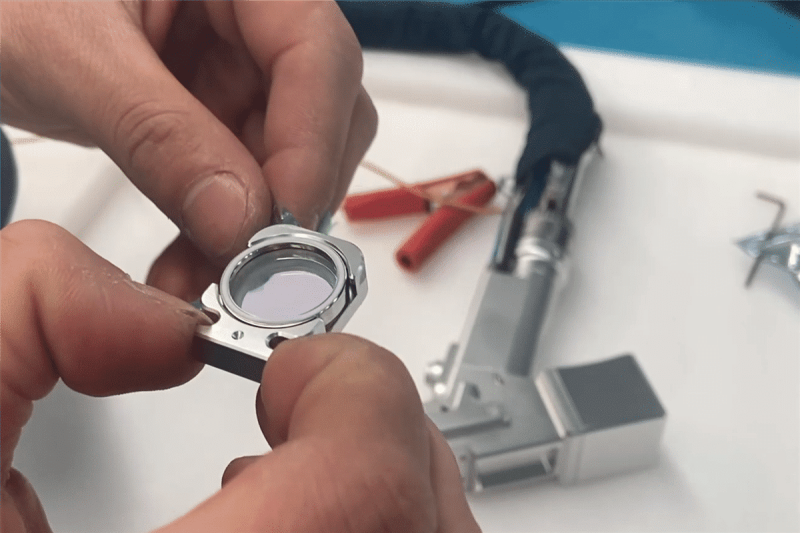

Precautions for Replacing Protective Lenses

The protective lens of the laser welding machine is located under the focus drawer assembly. When impurities or foreign objects are attached to the protective lens, the impurities or foreign objects will absorb laser heat and cause damage to the protective lens. Long-term use of a bad protective lens will cause damage to other lenses of the welding head, so the protective lens needs to be cleaned or replaced regularly. Usually, if the laser output energy is found to be weakened when the focal length and laser power do not change, it is necessary to check whether the protective lens is contaminated or damaged. When cleaning or replacing protective lenses, you need to pay attention to the following points:

- When there is dust on the protective lens, you need to use a lint-free cloth dipped in alcohol to gently wipe the front and back of the lens in one direction from top to bottom or from left to right, and blow the surface of the lens with an air blower to confirm that there is no foreign matter on the surface of the lens after cleaning.

- When cleaning and replacing the protective lens, you need to avoid oil stains on your hands dust in the environment, or dust outside the welding head from contaminating the protective lens, protective lens holder, and the inside of the laser welding head installation protective lens holder.

- When the protective lens is damaged, it needs to be replaced directly with a new one. When replacing the protective lens, please replace it in a dust-free environment. If it is not dust-free, please replace it in an environment with less air dust.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.