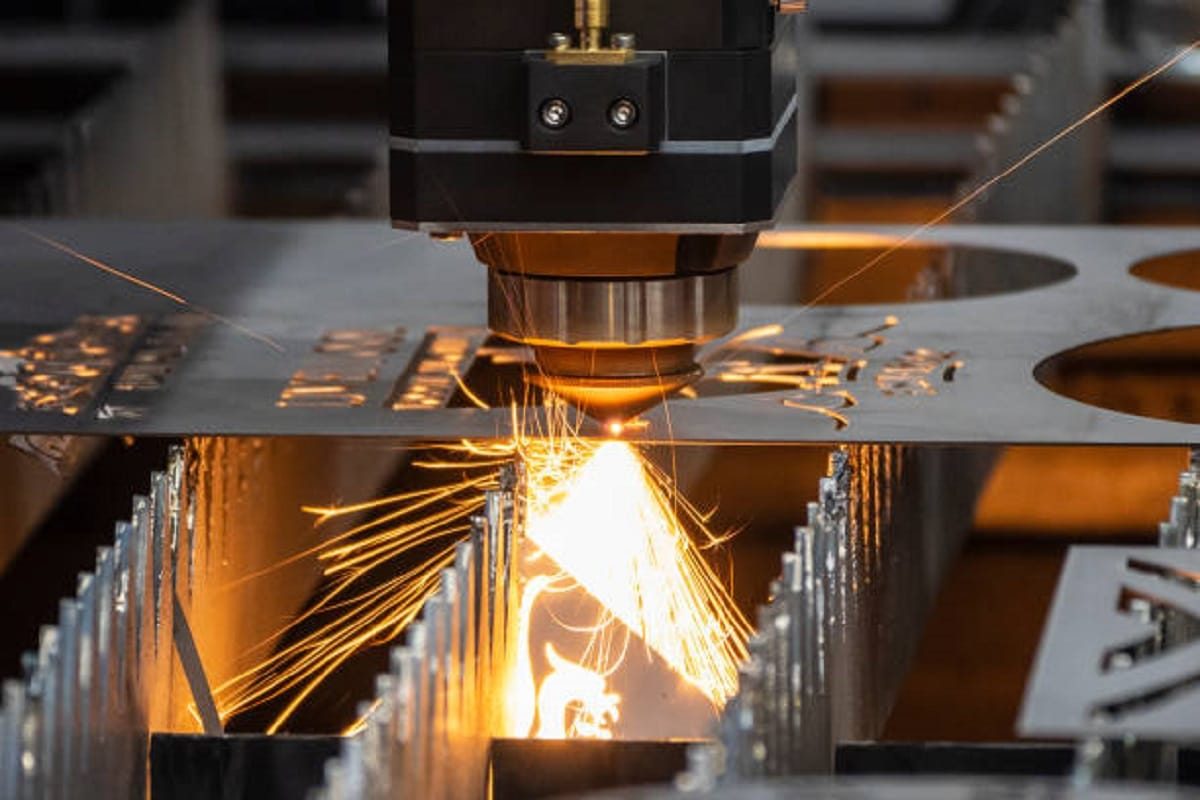

Introduction to laser cutting system

Laser cutting software is a specialized computer program that acts as the brains of your laser cutting machine. It is designed to control and manage the entire cutting process, allowing operators to transform digital designs into precise, realistic cuts. The role of the following software in laser cutting machines:

- Load and interpret cutting files.

- Define the path and speed of the laser.

- Monitor and control laser intensity.

- Ensure precision and accuracy of the cutting process.

Laser cutting control and operation software

Friendess

Advantages

- Cost-effectiveness: Friendsess is an affordable option for small businesses.

- User-friendly: Its user interface is relatively simple and suitable for users with limited experience.

- Basic cutting needs: The Friendsess is suitable for basic cutting tasks and is a practical choice for those with less complex requirements.

Disadvantages

- Limited advanced features: The software may lack some of the advanced features offered by more complex systems.

- Mainly for use with Chinese machines: It mainly works with laser cutting machines produced in China, which may limit its compatibility with other machine brands.

- Support and Updates: Friendsess may not offer the same level of comprehensive support and frequent updates as larger, more mature software solutions.

Weihong

Advantages

- Great value for money: Weihong is another affordable option for budget-conscious users.

- User-friendly: Similar to Friendsess, Weihong has a user-friendly interface ensuring easy operation.

- Compatibility: The software is known for its compatibility with various Chinese-produced laser-cutting machines.

Disadvantages

- Limited advanced features: Like Friendsess, the Weihong may lack the advanced features needed for complex cutting tasks.

- Specific machine models: It is primarily customized for specific Chinese machine models, which may limit its usability with other machines.

- Support and Updates: Ongoing support and updates may not be as robust as with larger software providers.

Au3tech

Advantages

- Accuracy and Reliability: Au3tech is recognized for its accuracy and reliability, making it an excellent choice for applications requiring high precision.

- Advanced Cutting: The software is equipped with advanced features to perform complex cutting tasks.

Disadvantages

- Limited user base: Au3tech may not have as large a user base as its more established competitors, which may impact the availability of user-generated resources and support.

- Training Requirements: Utilizing Au3tech’s advanced features may require operator and technician training.

Siemens

Advantages

- High reliability: Siemens is known for its reliability and precision in industrial applications, making it a trusted choice for demanding manufacturing environments.

- Comprehensive automation and control: Siemens offers comprehensive automation and control solutions covering all aspects of industrial processes.

- Industrial scale: Ideal for large industrial operations.

Disadvantages

- Cost: Siemens software is expensive and often requires a significant monetary investment.

- Complexity: The software is complex and its operation may require extensive training, making it more suitable for large-scale, industrial, dedicated operations.

- Compatibility: It may be customized specifically for Siemens hardware, which may limit its use with other machine brands.

ANCA Motion

Advantages

- Accuracy: ANCA Motion is known for its accuracy and high performance, meeting the requirements of high-end laser cutting machine

- Advanced features: The software offers advanced features suitable for complex cutting tasks and applications requiring real-time accuracy.

Disadvantages

- Complexity: The high complexity of ANCA Motion may require operator training to realize the full potential of the software.

- Features that are too advanced: ANCA Motion’s advanced features may not be necessary for smaller-scale operations, and advanced features can lead to increased complexity in operating the machine.

Beckhoff

Advantages

- Flexibility and scalability: Beckhoff software offers flexibility and scalability, making it suitable for integration into a wide range of industrial processes.

- Customization: The software allows customization to meet specific production requirements.

Disadvantages

- Complexity: Flexibility and functionality can make Beckhoff complex for small operations, and in-depth knowledge is often required to fully utilize its capabilities.

- In-depth knowledge required: Effective use may require in-depth knowledge of the software.

TRUMPF

Advantages

- Proprietary software: TRUMPF offers proprietary software customized specifically for TRUMPF laser cutting machines, ensuring seamless compatibility and robust support.

- Excellent service support: TRUMPF can provide customers with excellent customer support and comprehensive training.

- High-quality machines: The company is known for its high-quality machines and software.

Disadvantages

- Compatibility: TRUMPF’s software is designed primarily for TRUMPF machines, which may limit its versatility for use with machines from other manufacturers.

- Cost: High-quality and brand-specific software can be relatively expensive.

Raytools

Advantages

- Laser cutting heads: Raytools is a well-known laser cutting head manufacturer that offers specially designed software solutions to complement its equipment.

- Customization: Software functionality can be customized to meet specific laser head requirements.

Disadvantages

- Manufacturer dependence: The functionality of this software depends on the functionality provided by Raytools and may not have as broad a range of features as some catch-all solutions.

- Limited user base: Less user feedback and support than larger software providers.

Amada

Advantages

- High-quality machines: Amada is known for its high-quality laser cutting machines and offers proprietary software solutions designed to complement its equipment.

- Brand-specific support: Users benefit from brand-specific support, ensuring compatibility and reliability.

Disadvantages

- Brand-specific: Like TRUMPF, Amada’s software is primarily designed to work with Amada machines, which may limit its adaptability to other brands.

- Less versatile: It may not offer the same functionality or adaptability as other third-party software.

How to choose the best laser cutting system for your needs

Machine compatibility

Make sure the software and hardware are fully compatible with your specific laser cutting machine, as compatibility is the basis for a successful system setup.

- Check manufacturer compatibility to ensure seamless integration.

- Verify software and hardware version requirements to ensure the system functions optimally on your device.

- Compatibility with your specific laser cutting machine model.

Materials and mission compatibility

Consider the material you will be cutting and the complexity of the cutting task. Different software may be more suitable for specific materials or tasks.

- Evaluate material thickness and type to ensure the software will meet your specific needs.

- Assess cutting complexity, including 2D or 3D cutting, and ensure the software can meet your requirements.

- Consider material handling requirements such as panel size, loading, and unloading.

Budget

Determine the budget for hardware and software. Some systems are more expensive due to advanced features and extensive support.

- Consider software licensing costs and the financial investment required in hardware (including control units).

- Consider long-term ownership costs, including software updates, technical support, and maintenance.

Support and Service

Evaluate the level of support and service provided by software and hardware vendors. Strong support helps minimize downtime.

- Evaluate the availability of technical support.

- Ask about response times for support requests.

- Investigate whether user communities and forums exist for help.

User-friendliness

Assess your team’s expertise and training. User-friendly software may be more suitable for operators with limited experience, while more complex software may be suitable for trained professionals.

- Check the intuitiveness of the user interface.

- Determine training requirements and availability.

- Consider the machine operator’s learning curve.

Long-term viability

Research the supplier’s history and reputation in the industry. Choose a reputable vendor with a proven track record of software updates, support, and long-term viability.

- Explore the supplier’s history and years of industry experience to ensure stability.

- Analyze the frequency and consistency of software updates to keep up with industry trends.

- Look for user reviews and testimonials to measure user satisfaction and the overall reputation of the provider.

Future expansion

Consider your future business needs when choosing a laser-cutting system.

- Determine whether you need to expand your operation or integrate your laser cutting machine into a larger production system.

- Choose a system that can accommodate your growth by exploring scalability options.

- Investigate the system’s ability to integrate with other systems, such as manufacturing execution systems (MES), to ensure seamless future expansion.

User feedback and comments

Ask for feedback from users in your industry who have experience using the software and hardware you are considering. Real-world insights are priceless.

- Look for user reviews and ratings on reputable platforms to gauge current user satisfaction.

- Consider using reviews from users similar to your app to understand how well the software meets specific needs.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.