Introduction to Tube Laser Cutting Machines

What Are Tube Laser Cutting Machines?

Key Components of Tube Laser Cutting Machines

- Laser Source: Generates the laser beam required for cutting. Fiber lasers are commonly used due to their efficiency and ability to cut a wide range of f

- Cutting Head: Contains the focusing lens and nozzle, directing the laser beam onto the material with precision.

- Rotary Chuck System: Holds and rotates the tube or pipe, enabling 360-degree cutting operations and complex geometries.

- CNC Control Unit: The brain of the machine, interprets design files and controls the movement of the laser and material.

- Material Handling System: Automates the loading and unloading of tubes, enhancing productivity and safety.

- Assist Gas System: Uses gases like nitrogen or oxygen to aid the cutting process, improving cut quality and speed.

The Evolution of Cutting Technologies

Early Cutting Methods

Mechanical Cutting Technologies

Thermal Cutting Methods

Plasma Cutting

Introduction of Laser Cutting

Advancements in Laser Technology

Emergence of Tube Laser Cutting Machines

How Tube Laser Cutting Machines Work

Fundamental Principles of Laser Cutting

At the core of tube laser-cutting machines is the laser-cutting process itself, which involves using a concentrated beam of light to cut through materials. The laser beam is generated by a laser source and is directed, shaped, and focused onto the workpiece to perform the cutting action.

- Laser Generation: The laser source, such as a fiber laser, generates a high-powered beam of light at a specific wavelength.

- Beam Delivery: Optical components guide the laser beam from the source to the cutting head without significant loss of energy.

- Focusing the Beam: Lenses within the cutting head focus the laser beam to a small, precise spot on the material, achieving the high energy density required for cutting.

Key Components of Tube Laser Cutting Machines

Laser Source

- Fiber Lasers: Commonly used due to their high efficiency, low maintenance, and ability to cut a variety of metals.

- CO2 Lasers: Used for specific applications but are less common in tube cutting due to limitations with reflective materials.

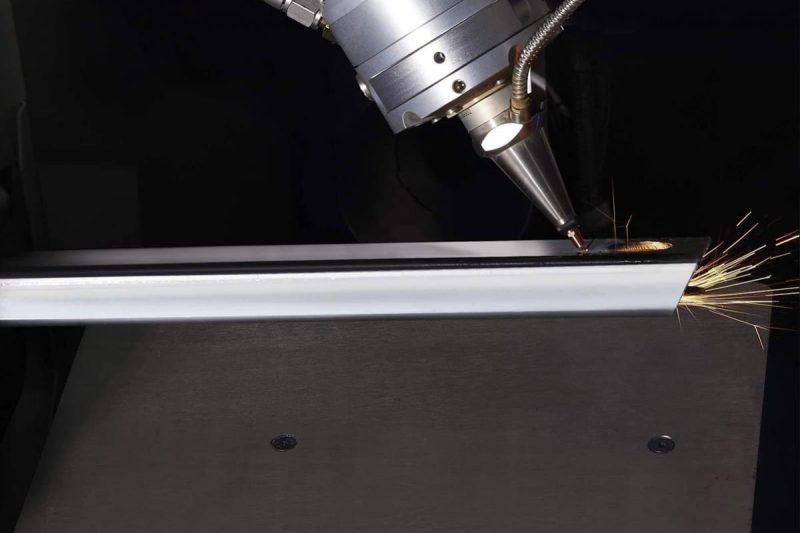

Cutting Head

- Focusing Lens: Concentrates the laser beam onto the workpiece.

- Nozzle: Directs assist gases (like oxygen, nitrogen, or air) to the cutting zone.

- Height Sensing: Maintains the optimal distance between the nozzle and the workpiece for consistent cutting quality.

Rotary Chuck System

- Material Holding: Secures the tube or pipe in place during cutting.

- Rotation Mechanism: Rotates the workpiece to allow for 360-degree cutting operations.

- Variable Clamping: Adjusts to accommodate different tube diameters and shapes.

CNC Control Unit

- Software Integration: Interprets design files from CAD/CAM software.

- Precision Movement: Controls the motion of the cutting head and workpiece with high accuracy.

- User Interface: Allows operators to input parameters and monitor the cutting process.

Material Handling System

- Automated Loading and Unloading: Speeds up production and reduces manual labor.

- Support Systems: Prevents tube sagging and ensures stability during cutting.

Assist Gas System

- Gas Selection: Uses gases like oxygen, nitrogen, or compressed air to aid in cutting.

- Function: Blows molten material away from the cut and cools the cutting area.

The Cutting Process Explained

Design and Programming

- CAD Design: The process begins with creating a detailed design of the desired part using Computer-Aided Design (CAD) software.

- CAM Processing: The design is then converted into a machine-readable format using Computer-Aided Manufacturing (CAM) software, which generates the cutting paths and sequences.

- CNC Programming: The CAM output is loaded into the CNC control unit, setting the parameters for the cutting operation.

Material Preparation

- Selection: The appropriate tube or pipe material is selected based on the project requirements.

- Loading: The material is loaded into the machine, often through an automated system that positions it accurately.

Alignment and Calibration

- Positioning: The rotary chuck clamps the tube, and sensors ensure it is correctly aligned.

- Calibration: The machine performs checks to confirm that all systems are set for optimal operation.

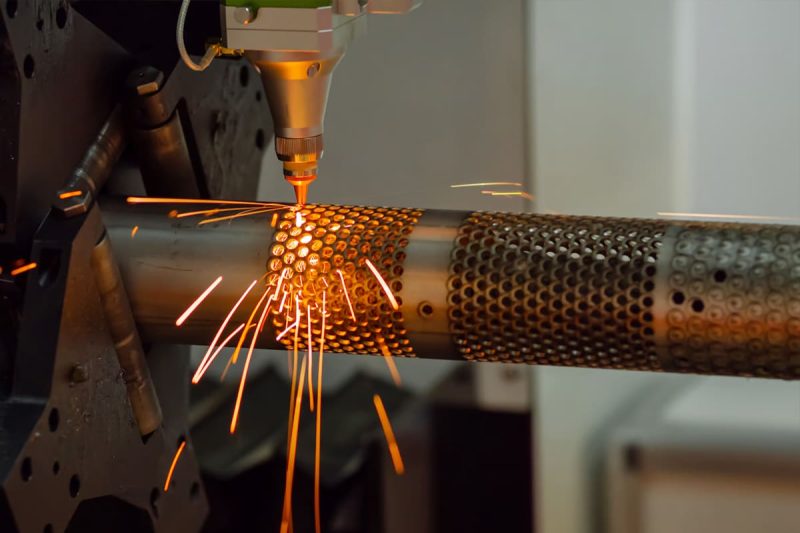

Cutting Operation

- Initiation: The laser source is activated, generating the laser beam directed toward the cutting head.

- Focus and Movement: The cutting head focuses the beam onto the material, melting or vaporizing it at the point of contact.

- Assist Gas Application: Simultaneously, the assist gas is emitted through the nozzle to expel molten material and protect the cutting area.

- CNC-Controlled Motion: The CNC system precisely controls the movement of the cutting head along the programmed paths while rotating the tube as needed.

- Complex Cuts: The machine can perform various cuts, including straight cuts, angled cuts, slots, notches, contours, and intricate patterns, all in a single operation.

Completion and Ejection

- Cut Verification: Sensors may verify that cuts are completed as programmed.

- Unloading: The finished part is automatically unloaded, and the next piece is prepared for cutting.

- Quality Inspection: Parts may undergo inspection to ensure they meet specified tolerances and quality standards.

Advantages of Professional Tube Laser Cutting Machines

Precision and Accuracy

One of the most significant advantages of tube laser cutting machines is their unparalleled precision and accuracy.

- High Tolerances: Achieve cutting tolerances as tight as ±0.1 mm, ensuring components meet exact specifications.

- Consistent Repetition: CNC control allows for the production of identical parts in large quantities without deviation.

- Complex Geometries: Capable of executing intricate designs and detailed patterns that are challenging with traditional methods.

- Minimal Distortion: The focused laser beam minimizes the heat-affected zone (HAZ), reducing the risk of warping or deforming the material.

Enhanced Efficiency and Productivity

Professional tube laser cutting machines significantly boost operational efficiency and productivity.

- High Cutting Speeds: Laser technology cuts faster than mechanical methods, reducing production time.

- Reduced Setup Times: Quick program changes and minimal tooling adjustments speed up the transition between jobs.

- Continuous Operation: Automation allows for extended run times, including unmanned shifts, increasing output.

- Multi-Functionality: Perform cutting, engraving, and marking in a single operation, streamlining processes.

Versatility in Material Handling

These machines offer exceptional versatility, accommodating a wide range of materials and profiles.

- Material Compatibility: Cut various metals including steel, stainless steel, aluminum, copper, and brass.

- Profile Flexibility: Handle round, square, rectangular, oval, and custom-shaped tubes and pipes.

- Thickness Range: Efficiently cut materials of different thicknesses, adapting to diverse project requirements.

- Application Diversity: Suitable for industries like automotive, aerospace, construction, furniture, and more.

Superior Cut Quality

The laser cutting process ensures superior cut quality, enhancing the final product’s performance and appearance.

- Clean Edges: Produces smooth, burr-free edges that often eliminate the need for secondary finishing.

- High Precision Cuts: Maintains tight tolerances even on complex shapes and intricate patterns.

- Minimal Heat Impact: Reduces thermal distortion, preserving the material’s structural integrity.

- Consistent Quality: Delivers uniform results across all parts, essential for mass production.

Reduction of Material Waste

Efficient material usage is a critical advantage of tube laser cutting machines.

- Optimized Nesting: Advanced software arranges parts to maximize material utilization.

- Minimal Kerf Width: The narrow laser cut reduces the amount of material removed.

- Error Reduction: Precision cutting minimizes mistakes that lead to scrap, saving resources.

- Cost Savings: Less waste translates to lower material costs and improved profitability.

Automation and User-Friendly Operation

Modern tube laser cutting machines are designed for ease of use and integration into automated workflows.

- CNC Control Systems: Intuitive interfaces simplify programming and operation.

- Automated Loading/Unloading: Reduces manual handling, speeding up production cycles.

- Real-Time Monitoring: Provides immediate feedback and diagnostics, enhancing process control.

- Safety Features: Incorporates protective enclosures and sensors to ensure operator safety.

Long-Term Cost-Effectiveness

While the initial investment is significant, the long-term financial benefits are substantial.

- Reduced Labor Costs: Automation decreases the need for manual labor, lowering operating expenses.

- Lower Maintenance Costs: Fewer mechanical components result in less wear and reduced maintenance.

- Energy Efficiency: Modern lasers consume less energy compared to older technologies.

- Increased Throughput: Higher production rates contribute to a quicker return on investment (ROI).

- Market Competitiveness: Enhanced capabilities allow you to take on more complex projects, attracting new customers.

Comparing Tube Laser Cutting with Traditional Methods

Traditional Cutting Methods

- Mechanical Sawing: Uses physical blades to cut metal tubes and pipes. It is relatively slow and less precise, and the blades wear out quickly, leading to increased maintenance costs.

- Plasma Cutting: Employs a high-velocity jet of ionized gas to cut through metal. It offers faster cutting speeds than sawing but often results in rough edges and lower precision.

- Oxy-Fuel Cutting: Utilizes a flame fueled by oxygen and gas to cut steel. It is effective for thick materials but lacks the precision needed for intricate designs and cannot cut non-ferrous metals.

Tube Laser Cutting

- recision and Accuracy: Offers unparalleled precision with the ability to execute intricate designs and maintain tight tolerances.

- Efficiency: Significantly faster cutting speeds and reduced setup times enhance productivity.

- Versatility: Capable of cutting a wide range of materials and profiles, including round, square, and custom-shaped tubes.

- Superior Cut Quality: Produces clean, smooth edges that often eliminate the need for secondary finishing.

- Automation: Integrates CNC control and automated material handling, reducing manual labor and the potential for errors.

- Cost-Effectiveness: Although the initial investment is higher, the long-term savings in labor, maintenance, and material waste make it more economical.

Industries Benefiting from Tube Laser Cutting Machines

Construction and Infrastructure

- Structural Components: Tube laser cutting machines enable the precise fabrication of beams, columns, and supports, enhancing the structural integrity of buildings and infrastructure projects.

- Architectural Designs: Allows for the creation of intricate metal designs for facades, railings, staircases, and other architectural elements, improving aesthetics without compromising strength.

- Efficient Production: Accelerates project timelines by reducing cutting and assembly times, leading to faster construction processes.

Automotive Industry

- Chassis and Frame Manufacturing: Provides accurate cutting for complex geometries required in vehicle frames and chassis components, contributing to overall vehicle safety and performance.

- Exhaust Systems: Enables precise fabrication of exhaust pipes and systems, improving engine efficiency and reducing emissions.

- Customization: Facilitates the production of custom parts for specialized vehicles, including prototypes and limited-edition models.

Aerospace and Aviation

- Aircraft Components: Ensures high-precision cutting of lightweight materials essential for aircraft structures, such as fuselage frames and wing components.

- Engine Parts: Produces components that meet strict aerospace standards, where accuracy and material integrity are critical.

- Space Exploration Equipment: Supports the manufacturing of parts for satellites and spacecraft with exacting specifications.

Furniture and Interior Design

- Innovative Designs: Allows designers to create unique and intricate metal furniture pieces with complex shapes and patterns.

- Custom Fixtures: Enables the production of bespoke lighting fixtures, fittings, and decorative elements that enhance interior spaces.

- Rapid Prototyping: Speeds up the development of new designs by quickly producing prototypes for testing and refinement.

Metal Fabrication and Manufacturing

- Versatile Production: Accommodates a wide range of projects, from small custom jobs to large-scale manufacturing runs.

- Precision Parts: Delivers high-quality components for machinery, equipment, and tools that require exact dimensions.

- Efficiency: Reduces production times and costs through automated processes and minimal material waste.

Medical Devices

- Surgical Instruments: Produces precise and intricate instruments necessary for complex medical procedures.

- Equipment Components: Manufactures parts for medical equipment like imaging machines and diagnostic tools, where precision is paramount.

- Compliance with Standards: Meets stringent medical industry regulations for quality and safety.

Custom Fabrication

- Artistic Projects: Assists artists and sculptors in bringing their visions to life by cutting complex shapes and designs in metal.

- Prototyping and Small Batches: Ideal for producing prototypes or limited runs of custom parts without the need for expensive tooling.

- Architectural Metalwork: Supports custom architectural elements like gates, signage, and decorative structures with high precision.

Key Factors When Choosing a Tube Laser Cutting Machine

Power and Capacity

The machine’s power and capacity directly affect its performance and the range of applications it can handle.

- Laser Power: Higher wattage lasers can cut through thicker materials and increase cutting speeds. Choose a laser power that matches the maximum thickness and types of materials you plan to work with.

- Cutting Capacity: Consider the maximum tube length, diameter, and weight the machine can accommodate. Ensure it can handle the sizes of tubes and profiles used in your projects.

- Material Compatibility: Verify that the machine can efficiently cut the types of materials you use, such as steel, stainless steel, aluminum, copper, or brass.

- Future Needs: Anticipate future projects that may require higher power or capacity to avoid outgrowing your equipment too quickly.

Software Integration and Control Systems

Advanced software and control systems enhance precision, efficiency, and ease of operation.

- CNC Control System: A user-friendly CNC interface simplifies programming and operation, reducing training time and the likelihood of errors.

- Software Compatibility: Ensure the machine’s software is compatible with common CAD/CAM programs for seamless integration from design to production.

- Automation Features: Look for features like automated loading and unloading, material handling systems, and real-time monitoring to boost productivity.

- Remote Diagnostics and Updates: Machines that support remote diagnostics can reduce downtime, and software updates can keep your machine current with the latest features.

After-Sales Service and Technical Support

Reliable after-sales service and technical support can help maintain operational efficiency.

- Installation and Training: Choose a manufacturer that provides comprehensive installation services and thorough training for your staff.

- Maintenance and Repairs: Ensure they offer prompt maintenance services, easy access to spare parts and have a responsive technical support team.

- Warranty: A solid warranty protects your investment and reflects the manufacturer’s confidence in their product.

- Customer Support Network: A global or well-established support network can provide quicker assistance when needed.

Brand Reputation and Reliability

The manufacturer’s reputation can be an indicator of the quality and reliability of their machines.

- Industry Experience: Manufacturers with a long history in the industry, like AccTek Laser, have proven expertise and reliability.

- Customer Reviews and Testimonials: Research feedback from other users to gauge satisfaction levels and machine performance in real-world applications.

- Quality Certifications: Certifications like ISO 9001 indicate adherence to international quality management standards.

- Innovation and Technology: Brands that invest in research and development are likely to offer more advanced and efficient machines.

Summary

Get Laser Cutting Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.